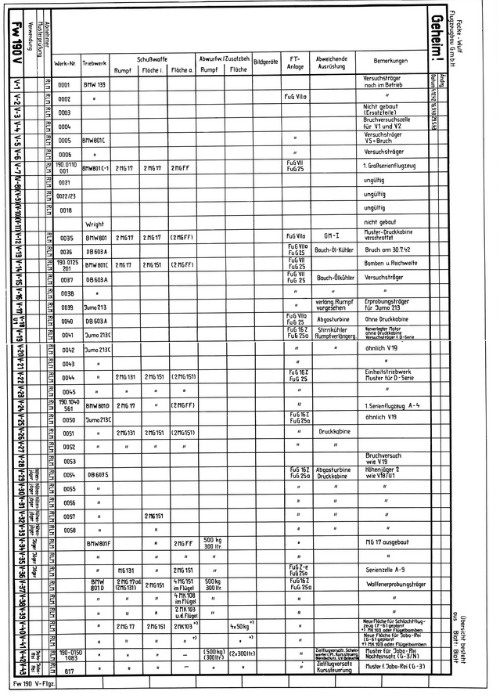

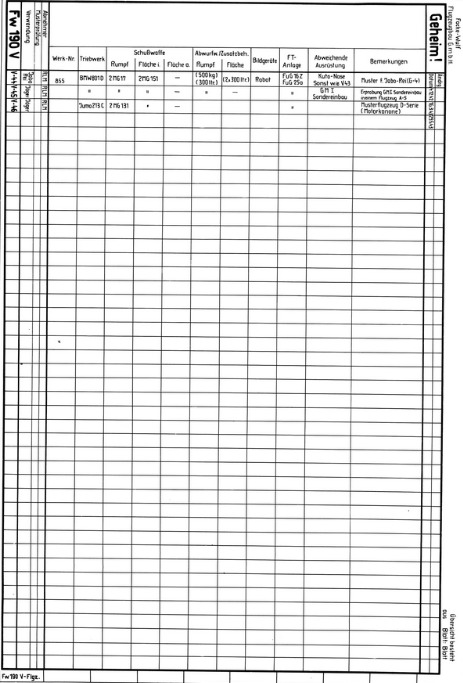

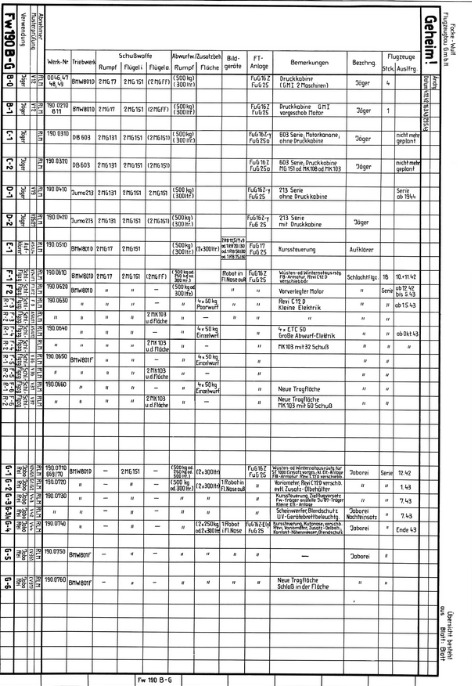

these information i provide could be wrong and not 100% right this topic just talks about fw 190d 15 /d14 / d13 / d12 / d11 / d9 engines & performance & data!

if you have better information feel free to share them !!

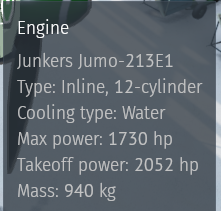

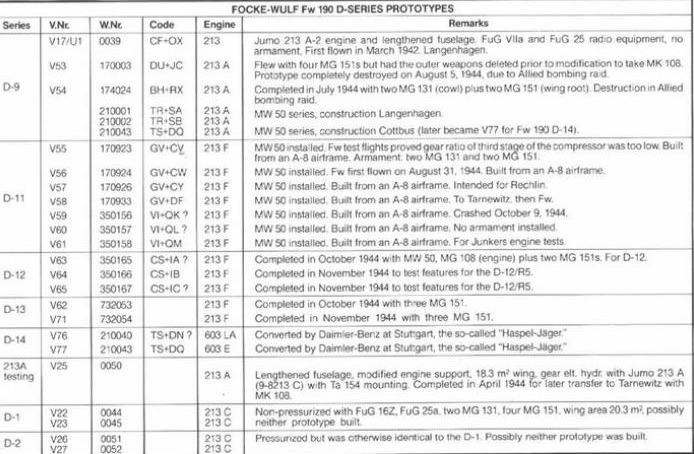

From all sources / books it point out that the fw 190 D13 engine is jumo 213F not the jumo E !

updated 1/16/2026. Added new data / Add new info about Fw 190 D14/15

Happy new year :D

brain hurts

fw 190 another book

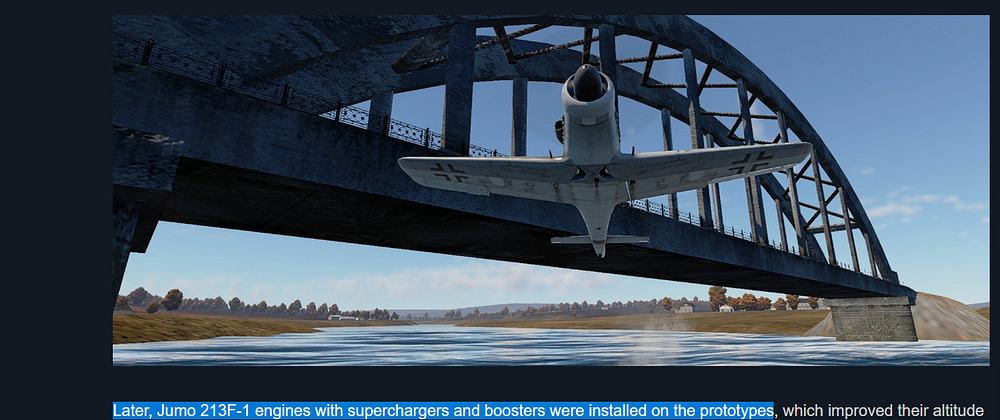

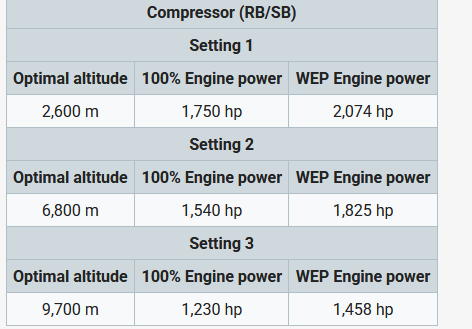

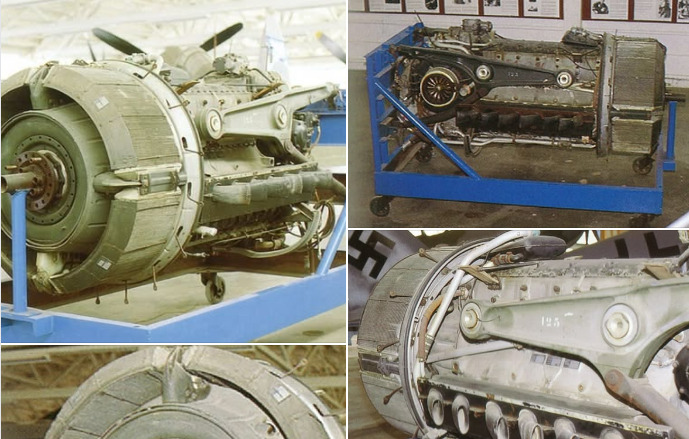

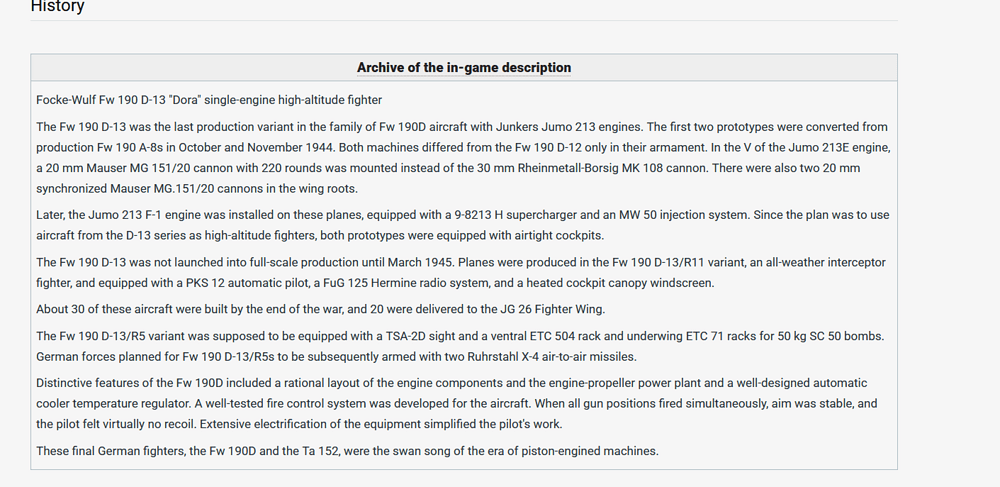

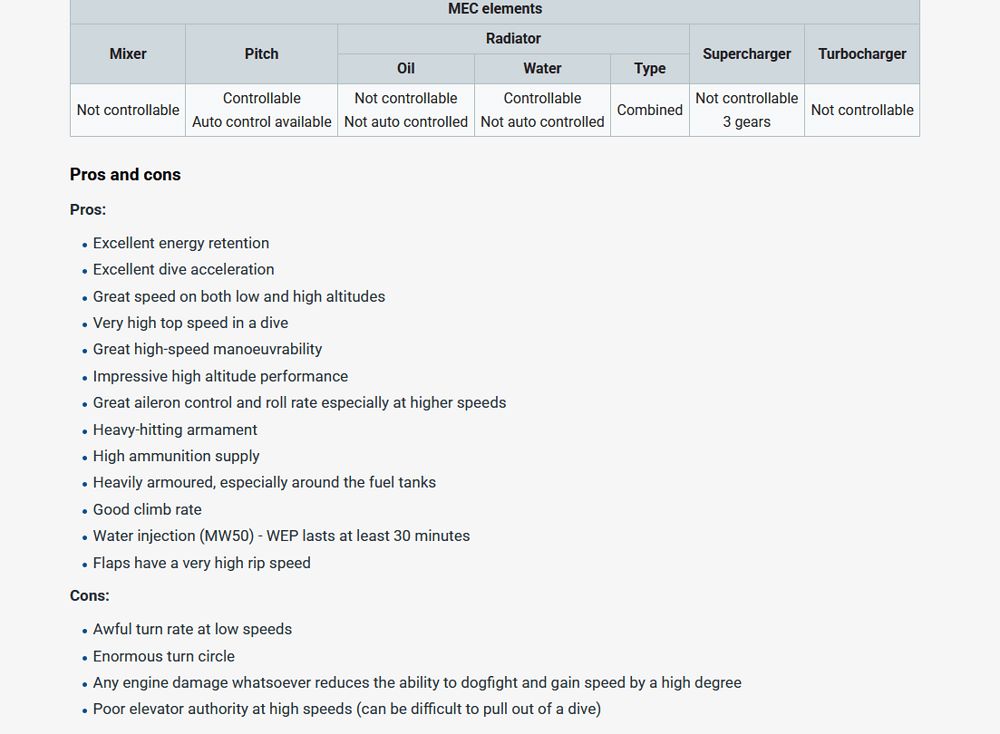

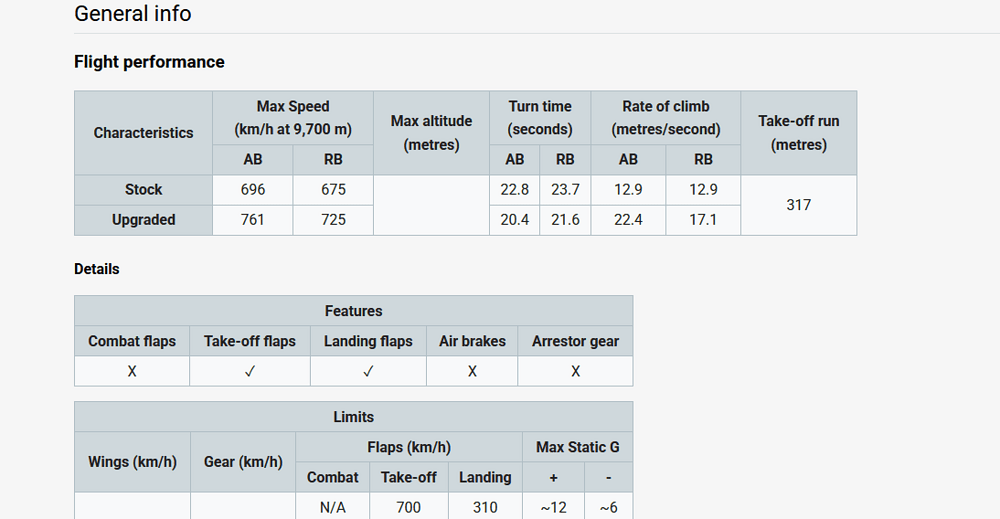

Fw 190 d13 in game

in game fw 190 d13

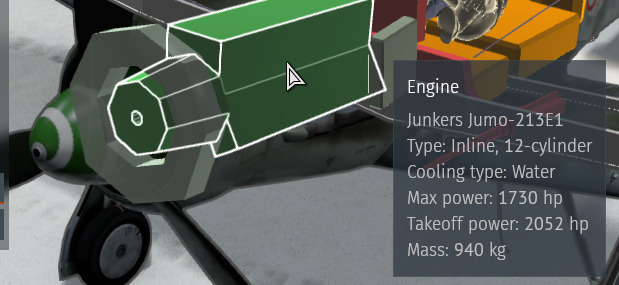

Max power (WEP): ~2,052 hp

Cruise power: ~1,730 hp

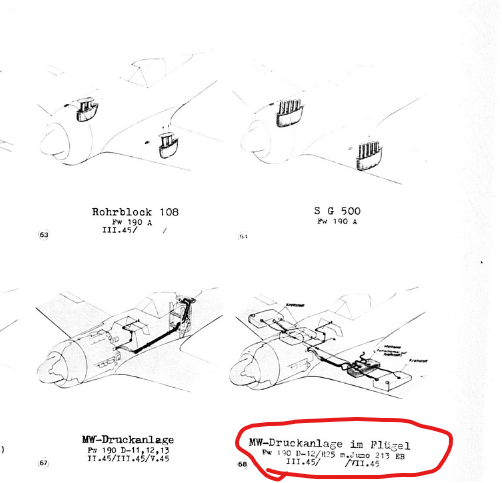

Boost system: MW 50 methanol-water injection

old wiki stats

old wiki stats

new wiki really bad at showing alt stats

new wiki image

new wiki image

but the engine could reach more !?

~2,050–2,250 hp with MW 50 boost

if these extra hp get added will help the plane a little bit in dog fights !

am trying to find books with data about the fw 190 d13 engines good source to bug report it

i found these info

that’s fw 190 d9

that’s fw 190 d9

https://ww2aircraft.net/forum/attachments/fw-190d-9-performance-pdf.619382/

WWII Fighter Performance

WWII Fighter Performance

First of all, this topic has been one of the most heated debates since it was first discussed during WWII. The data presented is based on continuing research.

The complex structure of aircraft and the manufacturing process, whether during a war time environment or not, makes each example somewhat unique, if not structurally but also from a performance standpoint due to structure finish, alignment, control surface and power plant rigging. Most aircraft manufacturers will only guarantee their published performance numbers within around 2 to 6 percent from one copy to the next even for modern aircraft. Atmospheric conditions, aircraft weight, field maintenance / rigging and operational abuse are also factors that need to taken into consideration.

The source of information can be more or less subjective than others and some information can be misrepresented as the numbers for the “type” as a whole. An example would be “P-51” without a reference to which sub-type of either “A”, “B”, “C” etc. and what external or internal variations or modifications existed on the particular aircraft being presented. Performance tests conducted by manufacturers, allied and well as axis, frequently are based on an aircraft that has been prepared for testing by smoothing the surface of the aircraft by various means which may include filling, sanding and polishing as well as properly rigging all flight controls and systems and these tests are conducted, typically by experianced test pilots. Also, the handling qualities and actual turn radius’s are rarely measured but are compared, one type against another, by pilots of varying ability and skill.

With this in mind W.W.II aircraft data, for ALL nationalities, should be taken as general guidelines and not absolutes. One aircraft will always be better or worse than the next, even of the exact same type, and this is verified from reading commentary of both combat and test pilots, of verying ability and experiance with these types of aircraft

If anyone has any additional information or data that you would like share or add to this page, or if you see any errors, please let me know.

The D-9’s that the U.S.A. and England had in it’s possession were reportedly equipped with additional boosting systems (MW-50, etc.) but detailed performance analysis has eluded me from these sources. Interestingly, the D-13 that the US had in their possession had MW-50 and GM-1. I do not know is the U.S.A. did any flight tests with the D-13 but flights of some extant, with at least 3 or 4 Fw190D-9’s, has been refered to in various literature and documents. The flight testing done by the British included the use some of additional boosting systems and give a completely different view, compared to U.S.A. testing, of this fine aircraft.

The Fw190D-9

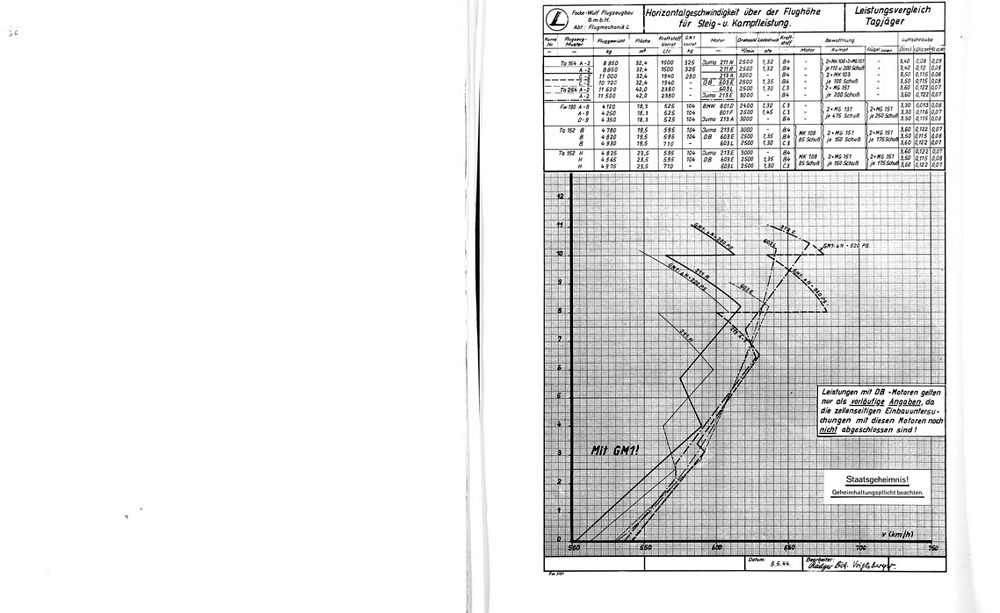

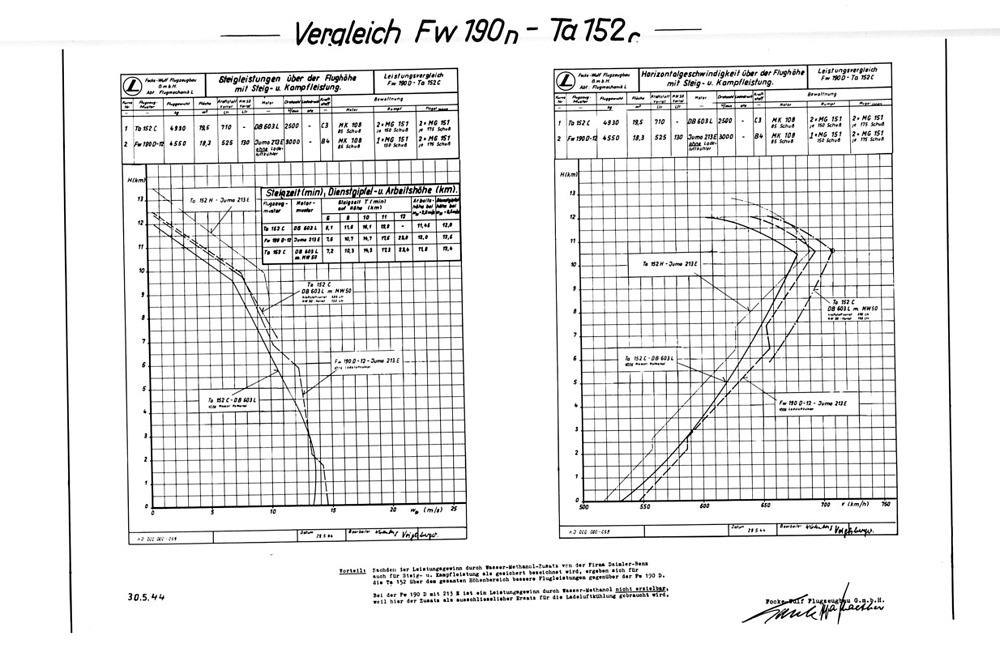

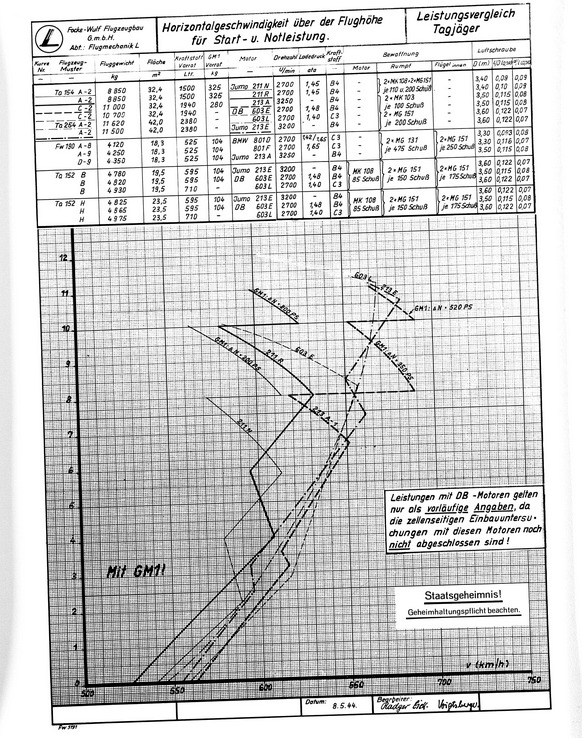

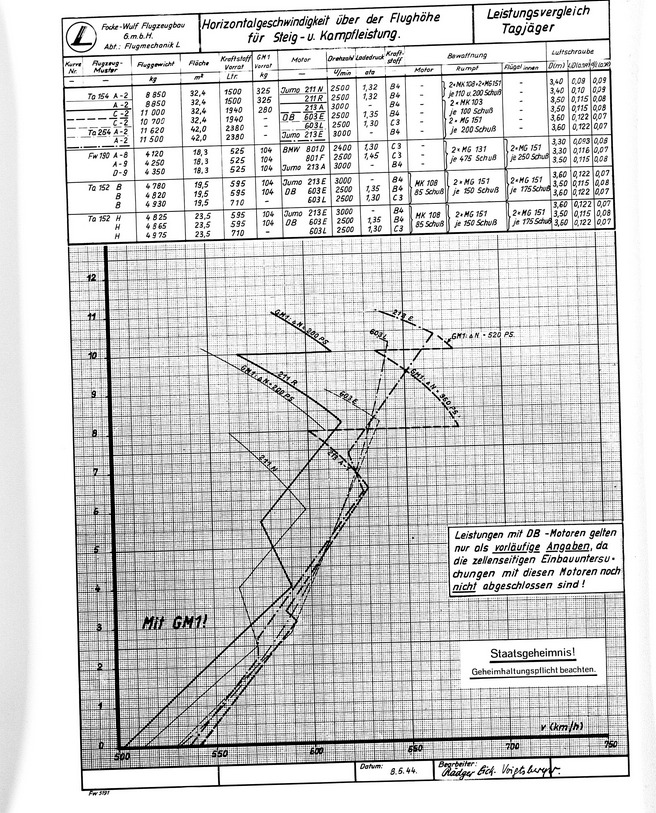

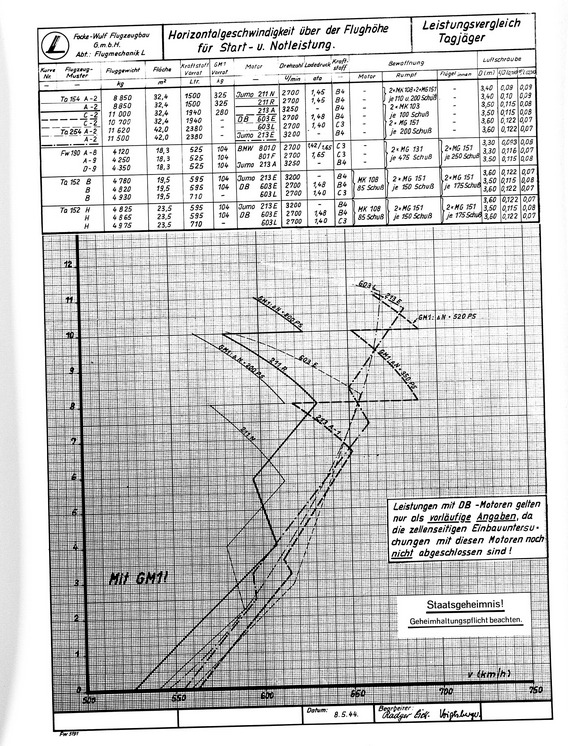

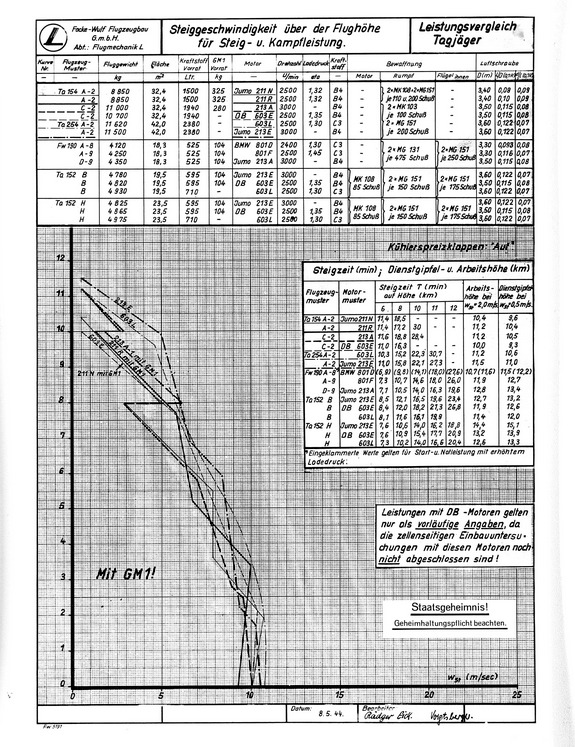

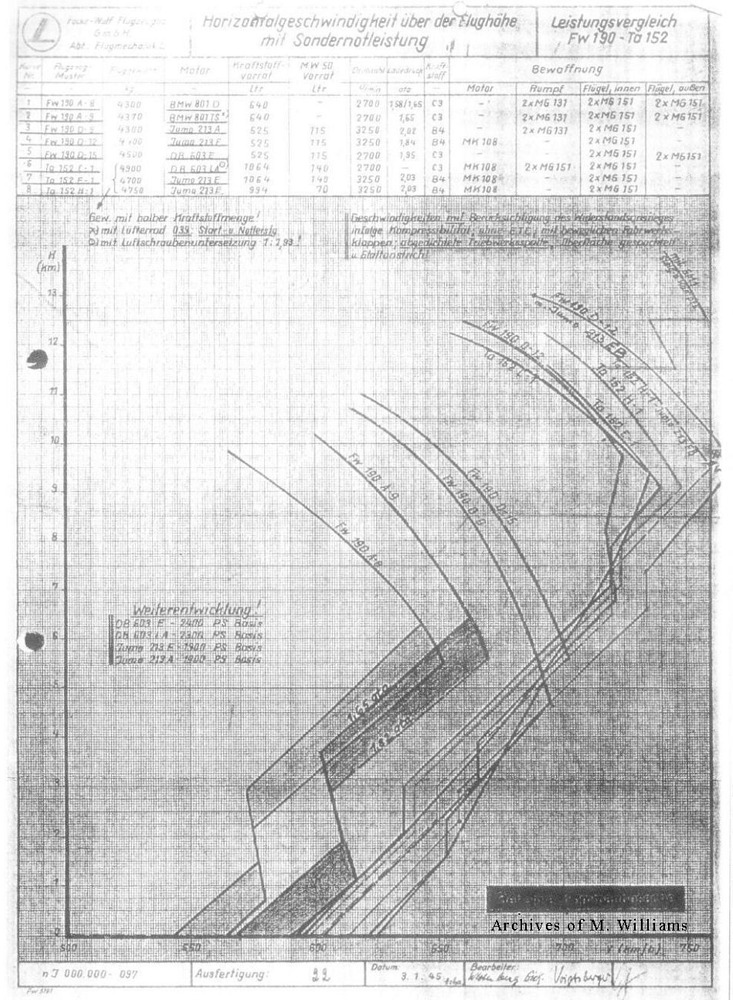

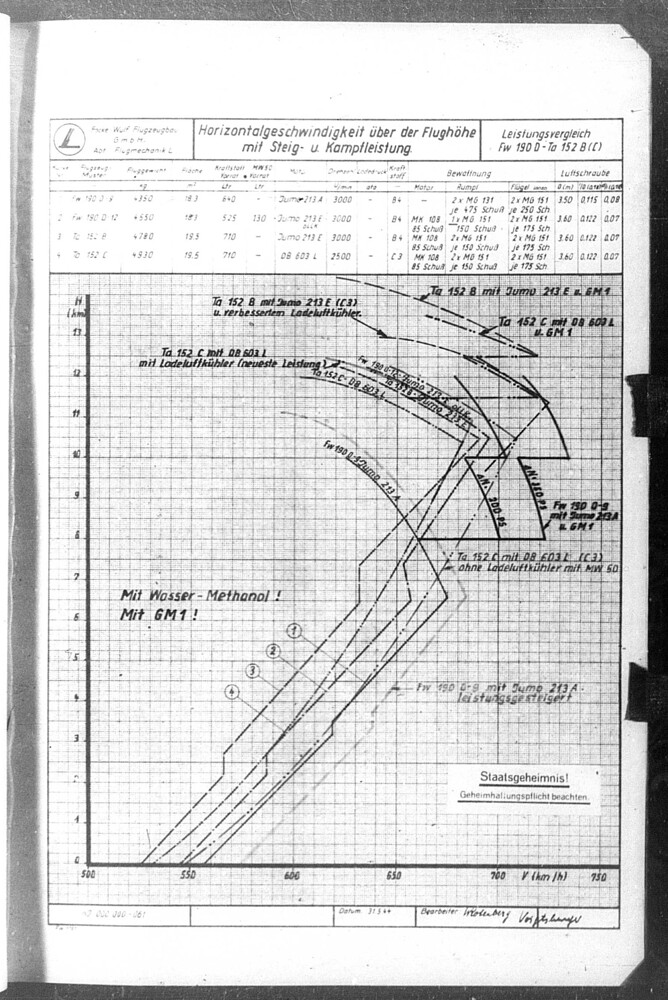

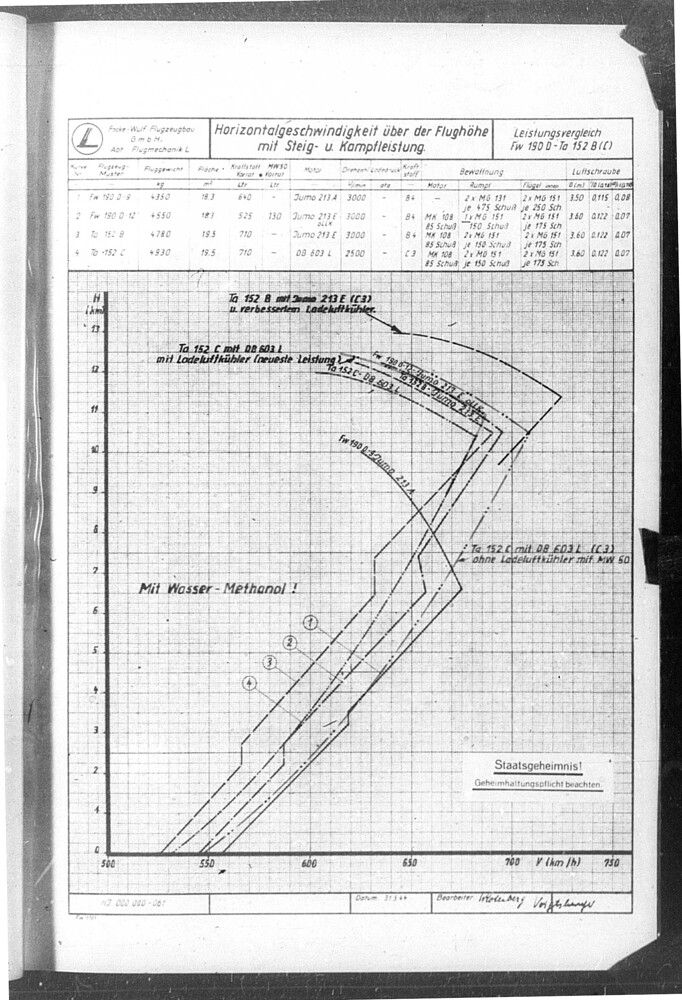

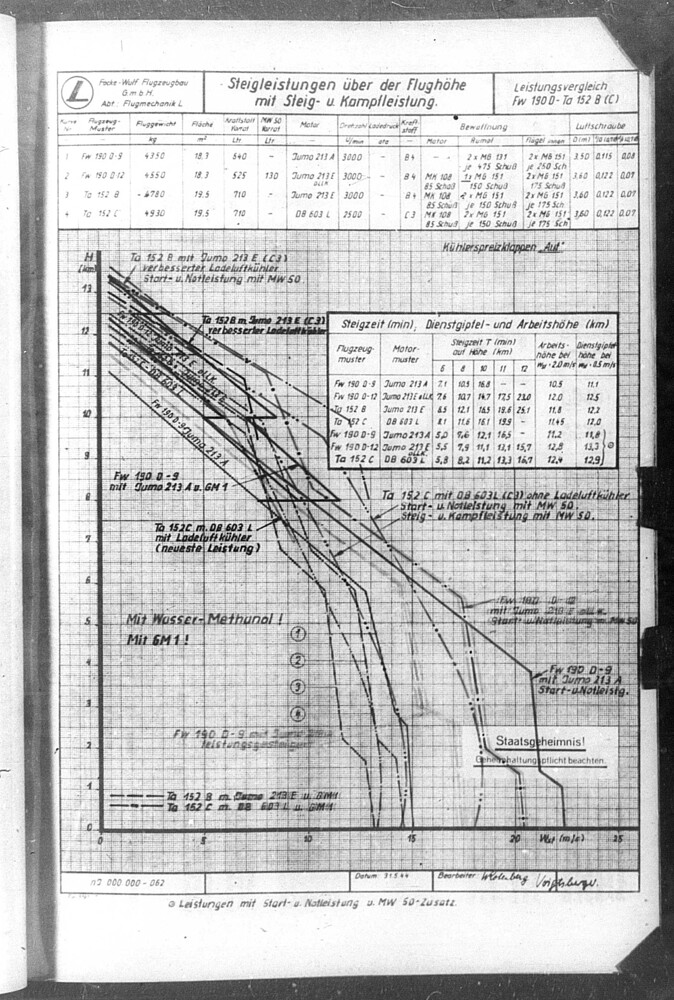

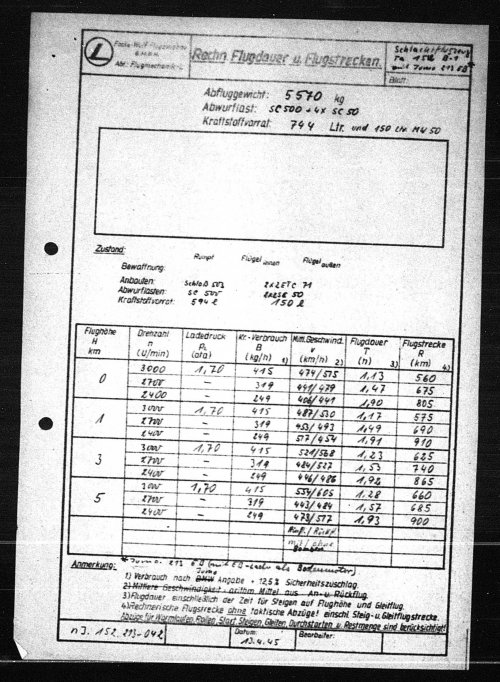

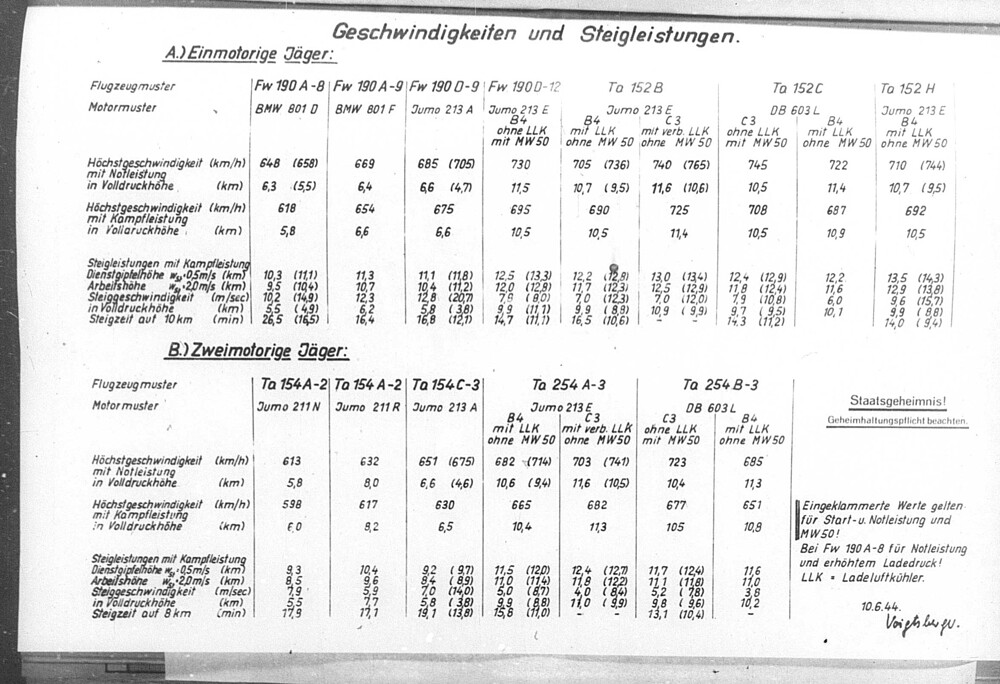

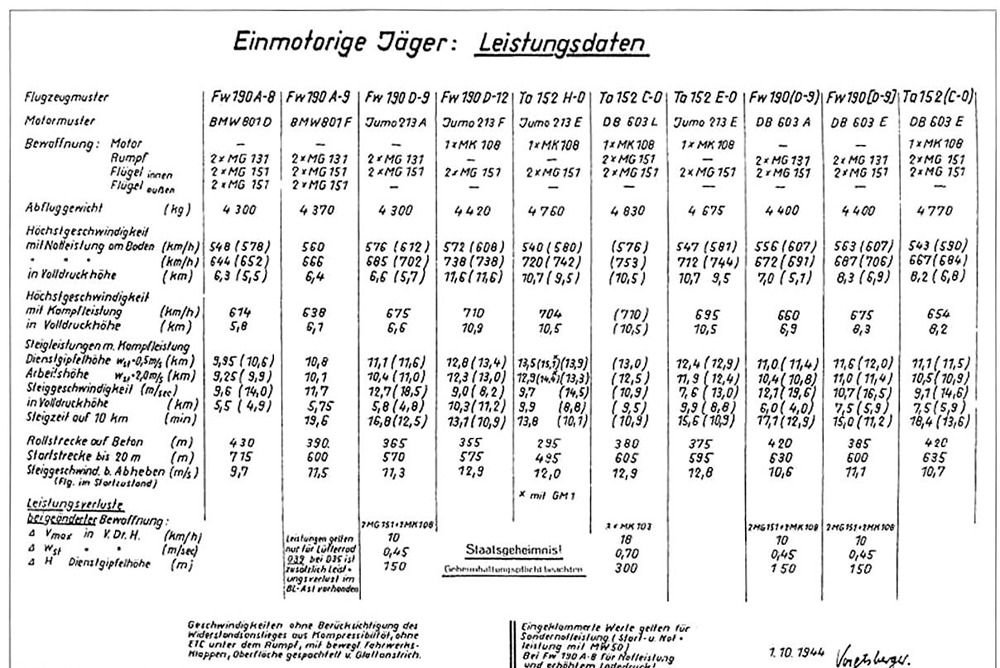

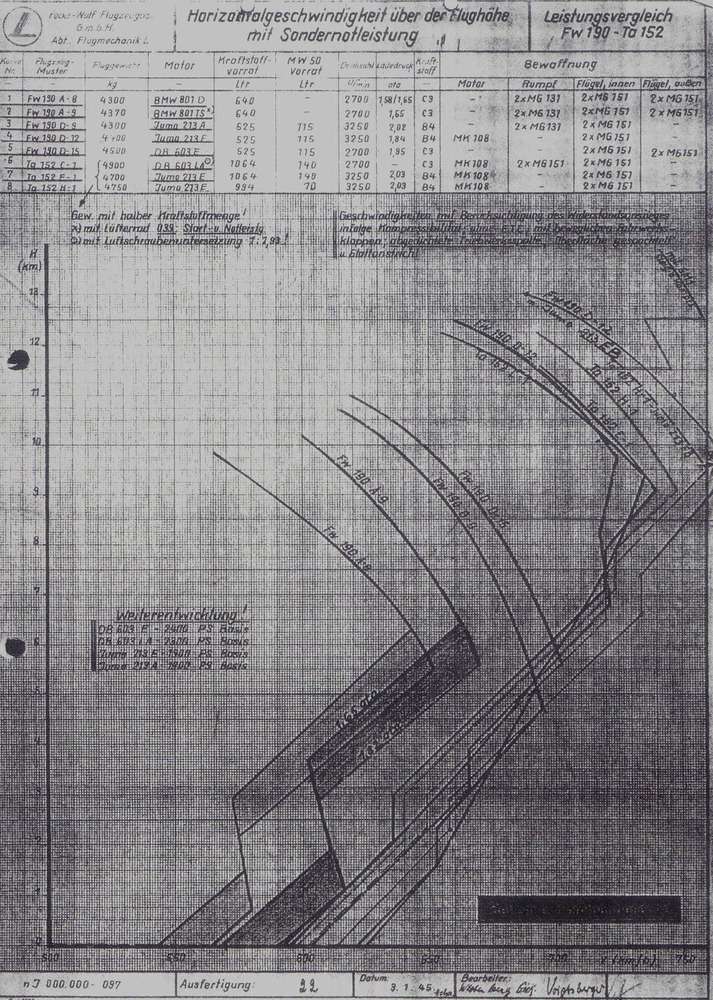

The following values are the most commonly used figures, for maximum speeds, in most publications from western sources and match captured manufacturers "Focke-wulf" test charts of a Fw190D-9 under Takeoff-Emergency power, using B4 / 87octane fuel, with a Jumo 213A-1 in May 1944. I suspect that the below figures are maximum speeds, with MW-50, of U.S.A. testing.

This gave the following speeds:

357 mph / 574 km/h (sea level)

397 mph / 639 km/h (10,830 ft / 3,300 m )

426 mph / 685 km/h (21,650 ft / 6,600 m )

397 mph / 639 km/h (32,800 ft / 10,000 m )

An early Dora with a stock Jumo 213A, without any modifications was not much of an improvement over the the Fw190A-8 except for somewhat better high altitude performance. The first production Dora’s soon received a field modification of a non-standard, low pressure, MW-50 installation “Oldenburg system” and a system referred to as “Ladedruckssteigerungs-Rüstatz” which increased power output of the Jumo 213A from 1750 to 1900PS without an additional boosting agent such as MW-50 or GM-1 up until the first of 1945 when production high pressure MW-50 kits, compressor modifications and C3 fuel were prevelant in D-9’s.

The addition of a “Ladedruckssteigerungs-Rüstatz” increased output from 1750 to 1900PS by allowing an increased maximum boost pressure , without an additional boosting agent. This could be used below 5000m and with the addition MW-50 gave an Emergency output of 2100PS. In addition, this enabled the previous “Emergency” power setting to be maintained for 30 min on the deck and the “Climb and Combat” power setting (1620PS) to be maintained indefinitely. This “Rüstatz” was in use with III/JG54 in October '44 and was in wide spread use with three other Jagdgeschwader by December '44.

From what I have read in one publication, 1 PS-Pferdestaerke is equivalent to approximately 0.986hp. Others have stated that 1 PS equals 1 hp.

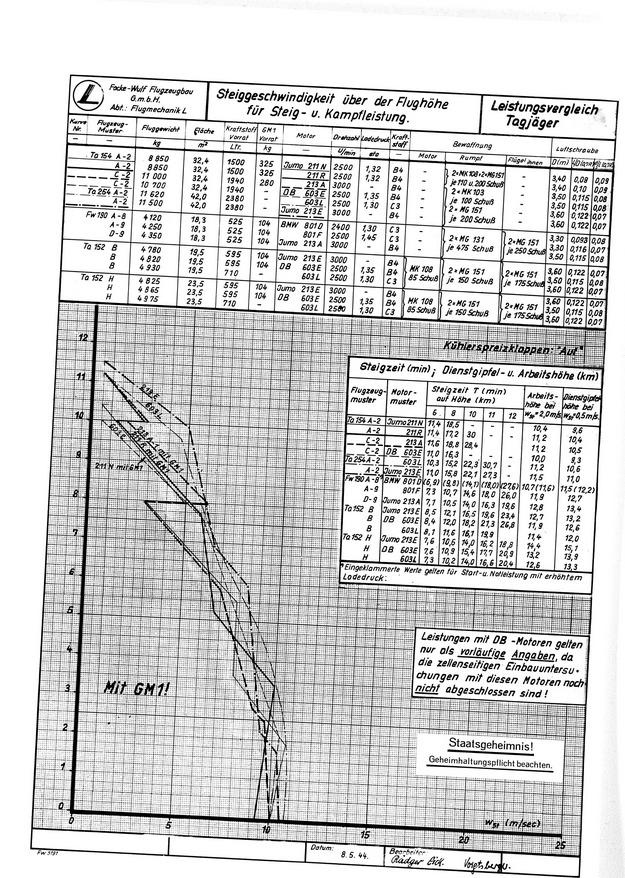

There are 5 speed curves represented on captured Focke-Wulf Flugzeugbau G.M.B.H. graphs available from the Smithsonian Institution. I have included additional tables for the use of GM-1 not represented on the

graphs from the Smithsonian but verified from U.K. documents. There is no known evidence that specifically states that GM-1 was used on the D-9 operationally but it was certainly possible since system and performance tests were accomplished… All these graphs and numbers are for a Fw190D-9 at it’s normal loaded combat weight ( 4,270 kg ) which includes; (2)MG131 (13mm) and (2)MG151/20 (20mm) guns along with the ETC 504 ordnance rack. It is probable that this aircraft was also “prepared” for testing but I have not been able to find comparable performance charts to verify this.

I have Fw190D-9 charts of testing done at Rechlin of series production aircraft that is completely stock, no modification to engine ( 1750 PS maximum ) or airframe as well as charts for a series production D-9 with the Ladedrucksteigerungs-Rüstazt ( 1900 PS maximum ).

The charts and performance presented on this web page present the very best performance, I believe, of a Fw190D-9 at normal gross weight with a ETC 501 ordnance rack with my best explanation of what the various power settings represent.

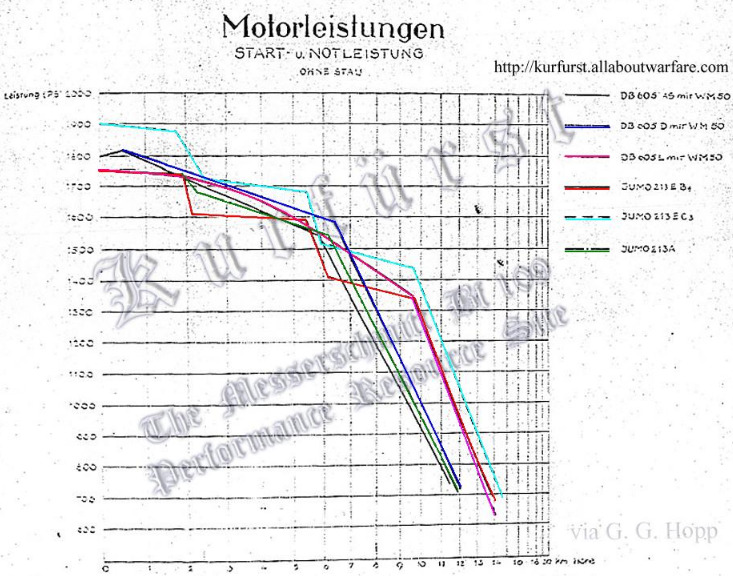

Power setting Translations;

1) Start -u. Notleistung - Takeoff & Emergency

Emergency power (i.e. take off or emergency) The Jumo 213 A-1 had a normal takeoff power of 1285kw (1750PS). A power output could be achieved, through a conversion kit, of 1395kw (1900PS) with increased boost pressure up to flight altitudes of 5000meters. The past takeoff performance (1750PS at ground level) could now be used for 30 minutes, and combat performance (1620 HP at ground level) became certified for continuous duty. This is the first sufficient measure to be corresponded that met the desires of the pilots for increase in output. With the “Ladedruckssteigerungs-Rüstatz” this becomes 1900ps, sustainable for 10 minutes.

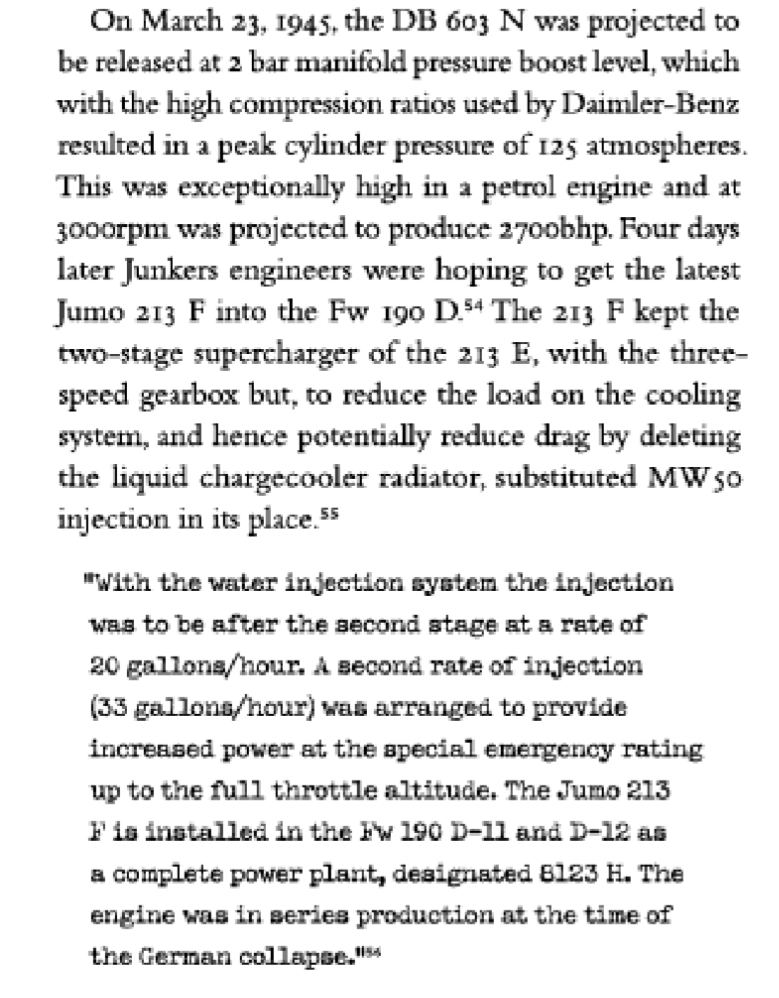

2) Sonder - Notleistung - Special Emergency

I believe this power setting is similar in principle to the Fw190A using “Erhöhte Notleistung” with C3 injection. That is, bleeding of the airline of the blower to induce a petrol surge and use it as a charge cooler. The setting was the same as in the A-8. There was a button, or lever, on the control panel to open the valve. To summarize, it was a petrol injection in the eye of the blower. It had the effect of allowing increased boost by its charge-cooling effect. It could only be used at full speed and 3,250 rpm. It was usable for 10 minutes, This power curve is listed with C3 fuel. I do not yet have a power curve to verify engine output in this configuration but it would be greater than 2100PS based on the speed and climb curves.

After the use of this Special Emergency power, no form of Emergency power could be used for at least five minutes

3) Sonder - Notleistung mit A Lader als Bodenmotor

Special Emergency power with compressor as the base-engine I am not really sure what this means.

I have viewed a chart that lists a similar power setting with a Ladergang which I believe is a special low altitude compressor gear. This appears to be an additional engine/compressor modification. I have no idea how many aircraft actually had this “power egg” or blower gear but the chart lists it’s use. I have speculated that the Dora “Red 13” of JV44 may have had one of these engines/ compressors. I do not have a engine power curve for this setting but based on the numbers it must have produced a significantly higher power than 2100PS at low altitude. This may be the 2240PS power setting?

4) Sonder - Notleistung mit Ladedruckerhoehung mit MW50 u. 1.8 ata. Special Emergency Power (with MW50) 2100PS at 3,250rpm, MW-50 at 150 l/h and B4 at 800 l/h.

Maximum power with MW50 was 2,100 hp at 3,250 rpm and was not to be used above 16,500ft. (around 5000 meters). In any case, the RAE tested the Jumo 213 A-1 with MW50, and at 21,000ft the engine

produced 1680 hp instead of the 1600 hp. At that altitude the output is the same whether you are using Takeoff & Emergency or Special Emergency power. This power setting was to be used for 10 minutes then 5 minutes at normal power before used again. The The Jumo 213A engine power chart also shows a dashed line at 2,240PS.

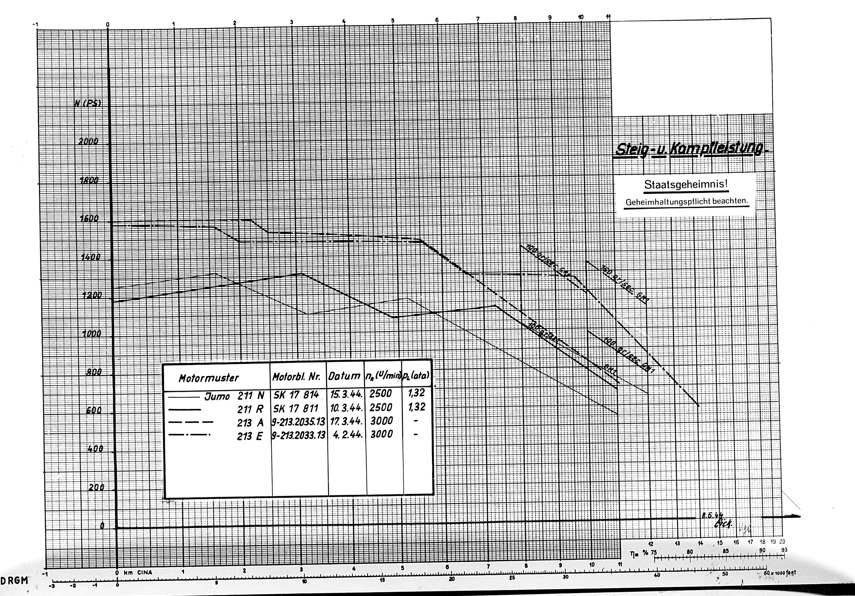

5) Steig - u. Kampfleistung-Climb & Combat

This could be maintained for 30 minutes with a stock Jumo 213A. With the “Ladedruckssteigerungs-Rüstatz” this power could be maintained indefinitely. Combat and Climb power covers the same principle as in any other plane. This is similar to what the UK documents have found: 1680 ps @ 3000 rpm.

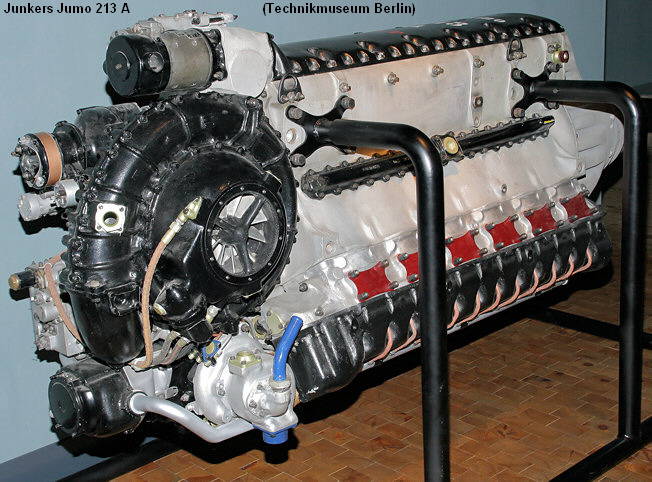

Engine types

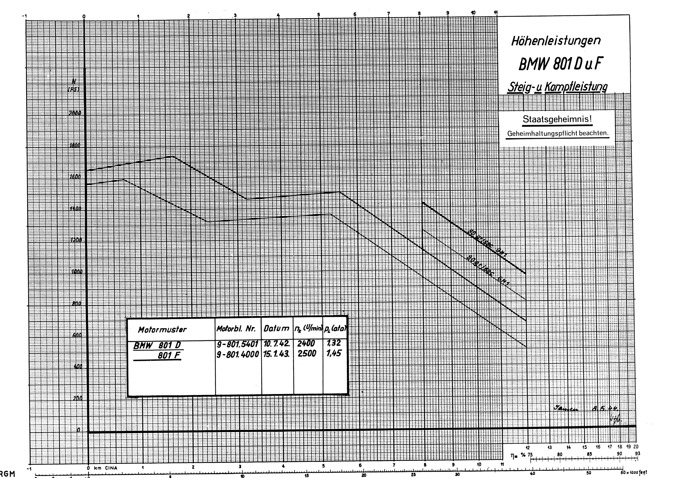

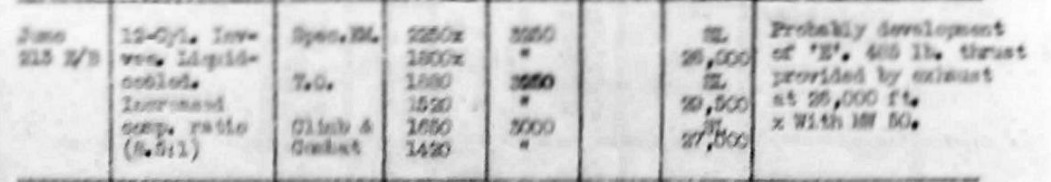

Jumo 213AG (single stage 2 speed supercharger) this unit unit had the single stage two speed supercharger optimised as “boddenladder” ie supercharger to increase power not compensate for speed. This unit achieved 2250hp, nevertheless it had good performance at all altitudes. This unit is associated with the 2240hp often mentioned.

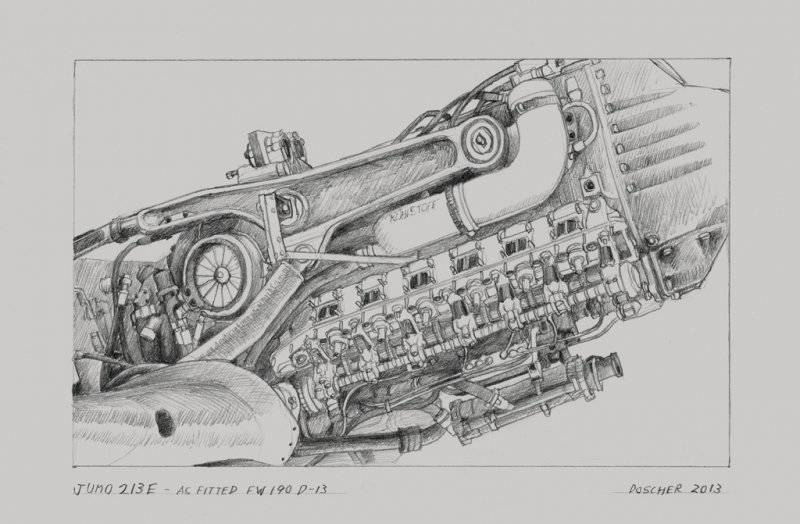

Jumo 213E (two stage intercooled 3 speed supercharger ) never saw service as the engine was optimised for C3 fuel and the anticipated shortages of C3 fuel forced the development of the Jumo 213E1, however a version of the Jumo 213E known as the Jumo 213F without the sizeable intercooler (probably housing cooling only)

Jumo 213E1 (two stage intercooled 3 speed supercharger ) which could use B4 fuel + MW50 + GM1. Used on Ta 152H and some Ju 88G7, Ju 88S3 and Ju 388 (test)

Jumo 213F (two stage non intercooled 3 speed supercharger) and interim version for the fw 190D13 Used on Fw 190D13. I believe had higher Compression Ratio but required C3 fuel to achieve same power as Jumo 213E1 due to minimal intercooling.

Jumo 213F1 (two stage non intercooled 3 speed supercharger) used a pump to inject MW50 instead of the less reliable supercharger pressurisation test flown on Fw 190D11 and intended for Fw 190D13

Note the difference between a Jumo 213F0 and Jumo 213F1 was that the F1 had a high pressure pump driven MW50 system whereas the F0 had only a supercharger blown low pressure system. Also different are that the F1 (like the E1) has a strengthened supercharger spline since 3rd gear tended to destroy the shaft when engaged on the F0 and E0 engine.

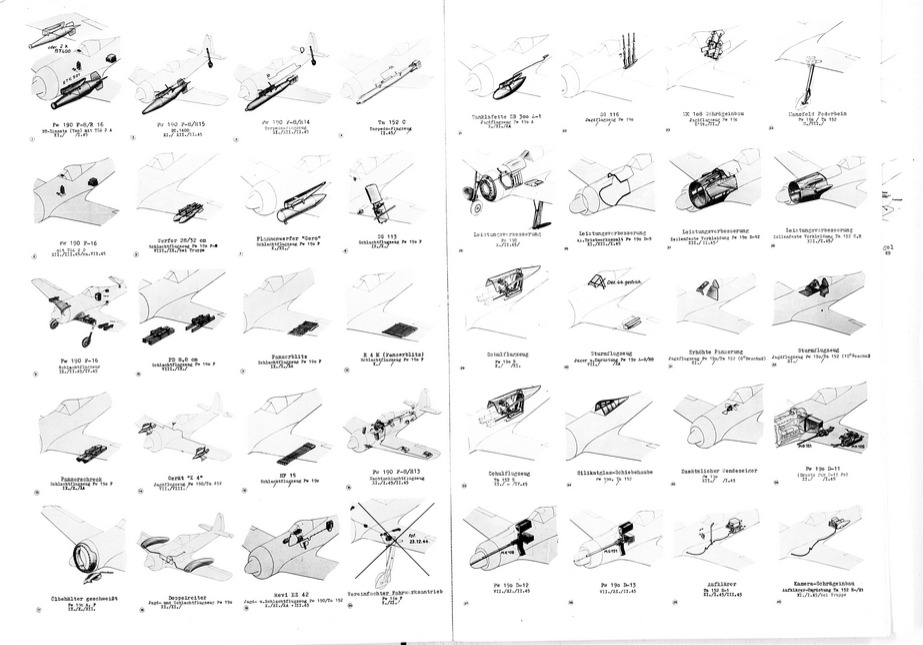

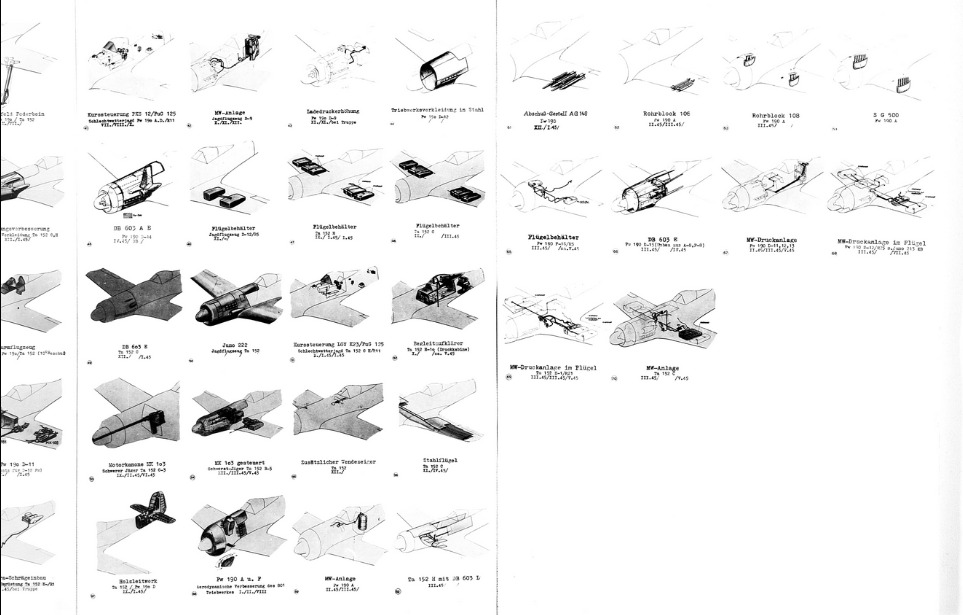

Extra fw 190 info

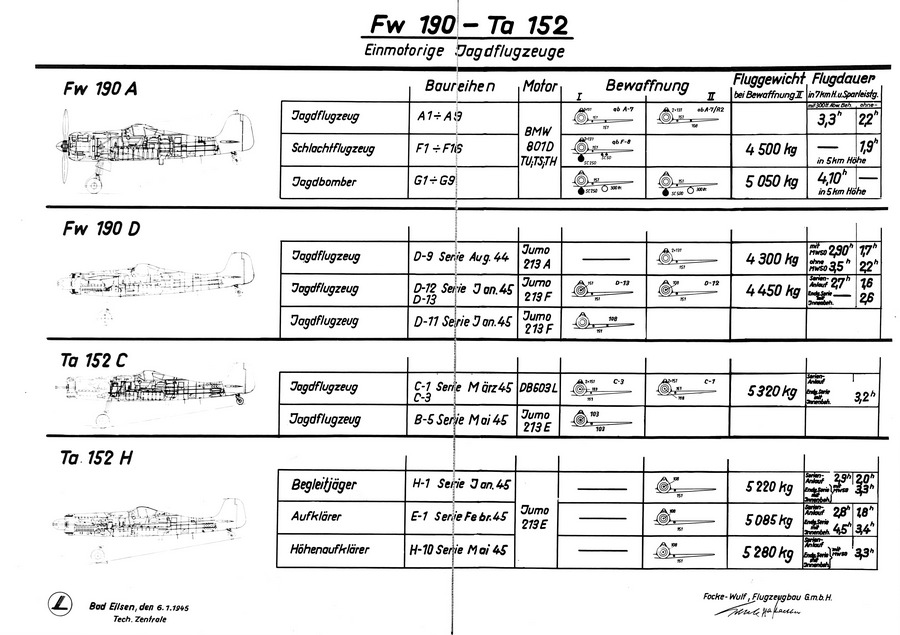

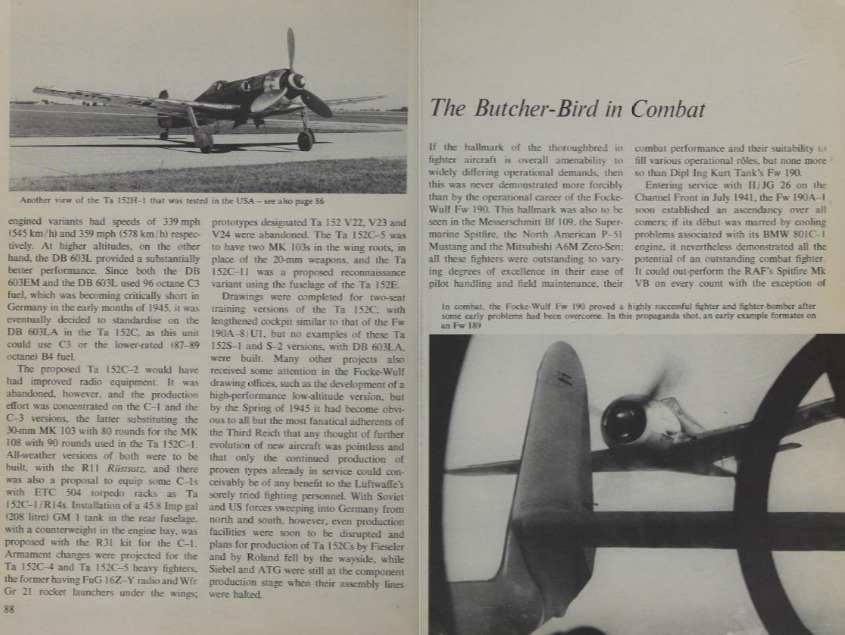

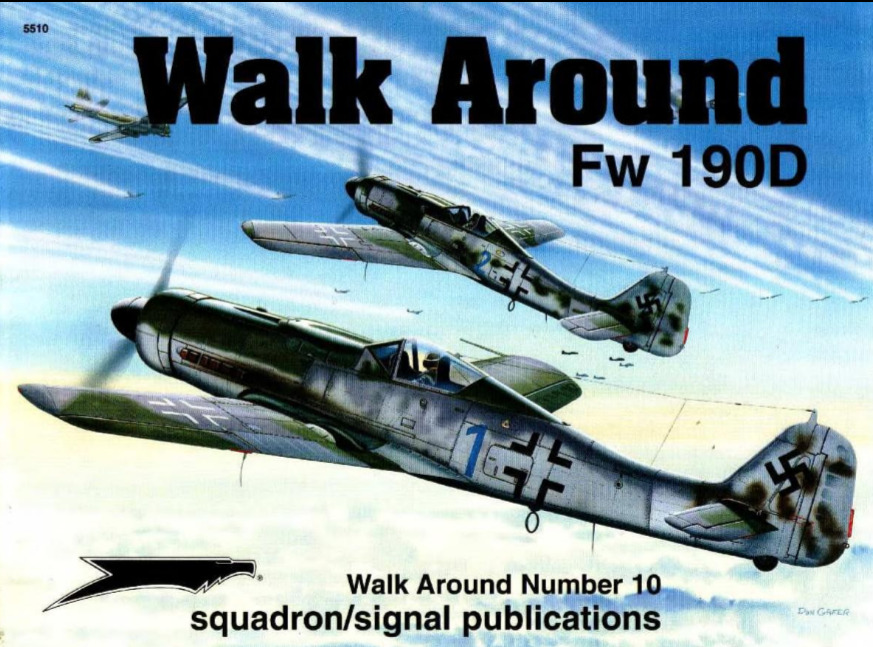

The Focke-Wulf Fw 190D was a high altitude version of the aircraft, powered by an inline engine hidden behind an extended version of the normal fuselage, making it look like a radial powered aircraft.

The Fw 190D was the third attempt to produce a high altitude version of the Fw 190. First came the Fw 190B, which used a turbo-supercharged version of the radial BMW 801 engine used in the Fw 190A. Second came the Fw 190C, powered by the inline Daimler-Benz DB 603 engine. Both of these variants suffered from problems with their turbo-superchargers, and work on them was soon abandoned because of the success of the Fw 190D.

The Fw 190D used the 1,750hp Jumo 213 A twelve-cylinder in-line liquid cooled engine. Some work on matching the Fw 190 to this engine began as part of the same programme as the Fw 190B and Fw 190C, with two versions suggested – the D-1 with a normal cockpit and the D-2 with a pressurised cockpit. Prototypes were allocated to both projects – V22 and V23 for the D-1 and V26 and V27 for the D-2. One Fw 190, V17, had already been given a Jumo 213 engine during 1942, and was flying by the end of the year. However the project really gained impetus early in 1944, during the development of the Focke-Wulf Ta 152.

Early in 1943 Kurt Tank began work on a new fighter, with a superficial resemblance to the Fw 190 but using a new airframe. In April 1943 the RLM (German Air Ministry) gave this aircraft the designation Ta 153, but soon afterwards they rejected it on the grounds that it would cause too much disruption on the production line. Tank responded with an aircraft that used more components from the Fw 190, and in May this was designated as the Ta 152A and Ta 152B, one using the Daimler Benz DB 603 and the other the Junkers Jumo 213. In December 1943 the Ta 152H, a high altitude version, joined the development programme.

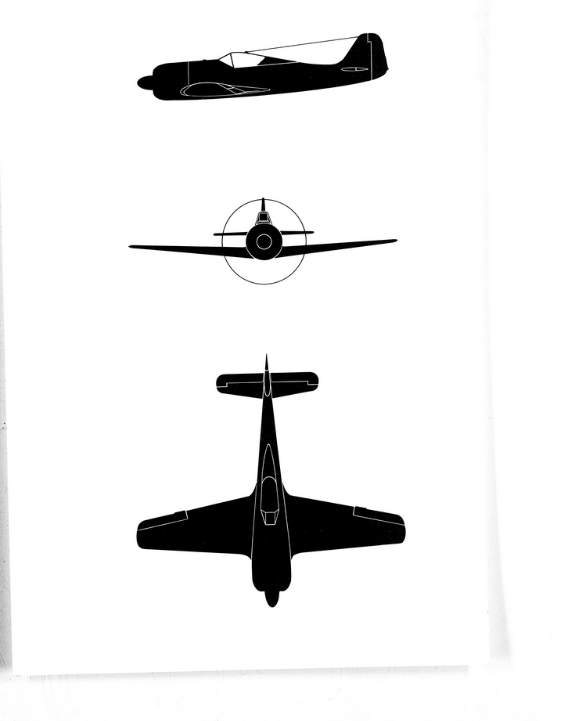

![]()

Focke Wulf Fw 190D from the left

The RLM also wanted a quick solution alternative (Schnellosung). At a meeting on 5 July 1943 Messerschmitt and Focke-Wulf were both asked to produce designed for high altitude fighters that used as many components from their standard fighters as possible. Tank already had a series of designs under way (Rechniersiche Ankundigung¸ or Analytical Prospectus), which had been under development since early in 1942. Of these Ra-1 and Ra-8 were both powered by the Junkers Jumo 213A engine. Ra-1 used the standard Fw 190A wing with a hydraulic undercarriage, while Ra-8 used the standard Fw 190A wing but with an extended rear fuselage.

On 13-14 January 1944 Tank suggested producing an interim design, using as much as possible of the airframe from the Focke-Wulf Fw 190A-8 with the Junkers Jumo 213A engine. This option was expected to take less time to complete than any version of the Ta 152, and would also provide security against a shortage of the BMW 801 engines used in the standard Fw 190. This project was approved, as the Fw 190D-9 (to match the A-9, then under development). At some point the D-1 and D-2, and their main prototypes, were cancelled.

The Jumo 213 was longer than the BMW 801 radial engine used in the Fw 190A, and so the ‘Dora’ had a longer nose to carry the engine and a 50cm extension in the rear fuselage to balance it. It also used the larger tail fin already under development for the Ta 152. Bigger wheels and a strong engine mount were required to cope with the heavier engine. The D-9 used the same undercarriage, wings, radio and electronics as the A-8 and A-9. The appearance of the aircraft didn’t change as much as one might have expected with the change from a radial to an inline engine, as the Jumo 213 was contained within a similar circular fuselage, with a ring-shaped annular radiator between the engine and the propeller.

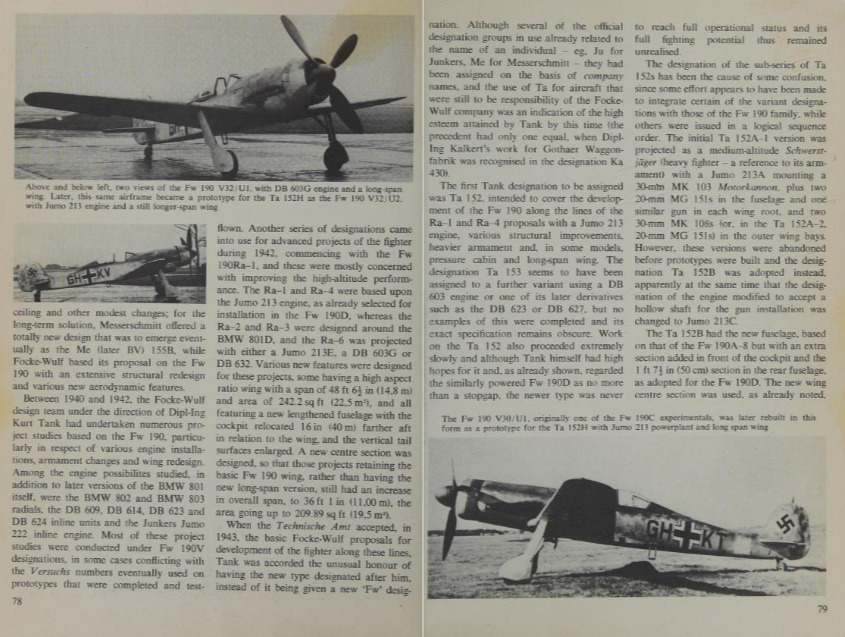

The first prototype for the D-9 was produced by putting the Jumo engine in the V 17 prototype. This was the engine that had originally been allocated to this aircraft, and was probably installed in 1942, but it may later have been given a DB 603. If so that was now replaced with the Jumo 213 as the V 17/U1. It made its maiden flight in this format on 17 May 1944, and then went to Rechlin for tests that lasted from 11 June-6 July.

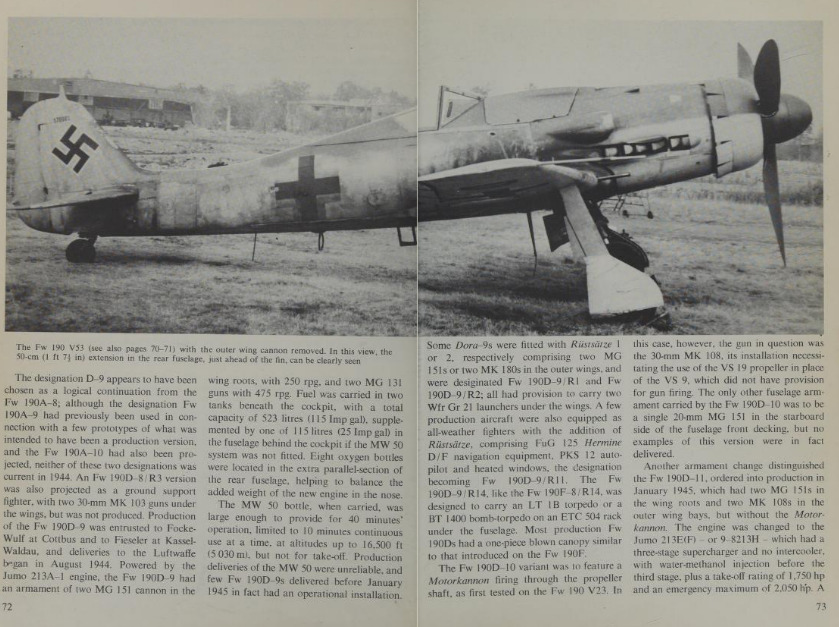

It was followed by the second prototype, V53, which made its maiden flight by 12 June. This version used a Jumo 213 CV engine that had space for a cannon to fire through the propeller hub.

![]()

Plans of the

Focke Wulf Fw 190D

The third prototype, V54, introduced the MW 50 boost system. This used a mixture of methanol, water and anti-corrosives that could be injected into the supercharger for up to ten minutes at a time, boosting power from 1,750hp to over 2,200hp and raising the top speed to 426mph from 360mph.

On 5 August 1944 the Americans bombed the Focke-Wulf plant at Langenhagen, destroying or damaging a number of Fw 190 and Ta 152 prototypes. Amongst them was V53, which was damaged, and V54, which was destroyed. However by that point the D-9 had already entered production, and the first was completed at Focke-Wulf’s Cottbus factory in the summer of 1944. Fieseler, Mimetall and Dornier also produced the D-9, while some may have been converted from A-8s at Focke-Wulf’s Langenhagen facility.

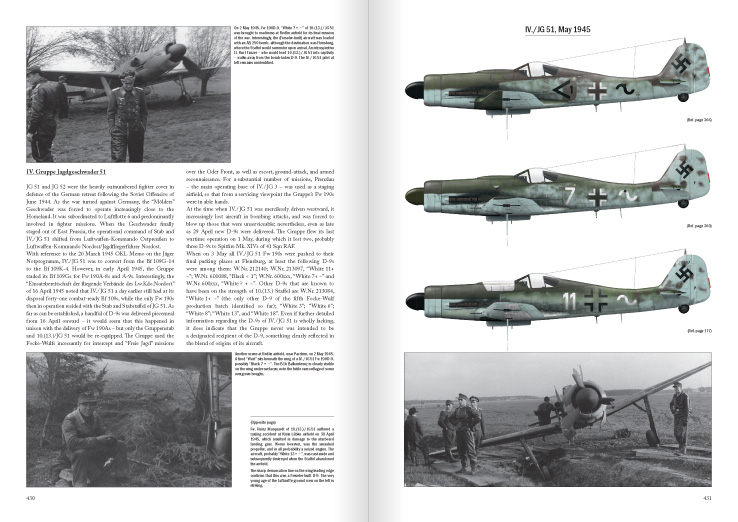

The Fw 190D-9 had a similar performance to the P-51D Mustang and the Spitfire Mk XIV, but it arrived rather too late, in too small numbers and at a time when the Luftwaffe was critically short of fuel. The first unit to gain them was III./JG 54 ‘Grunherz’, under Hptm Robert ‘Bazi’ Weiss, which got them in September 1944 then moved to bases at Hesepe and Achmer near the Dutch border, to protect the Me 262 jets of Kommando Nowotny, which were vulnerable when taking off and landing. On 8 November 1944 the group lost three pilots, including Major Mowotny, when they were attacked by a formation of P-51s. The group was then withdrawn to form the core of the first jet fighter wing, Jagdgeschwader 7. III./JG 54 remained in combat, suffering its worst day on 29 December when it lost six pilots. It became IV./JG 26 on 25 February 1945, under Major Hans Klemm.

The second D-9 unit was II./ JG 26 ‘Schlageter’ (Major Karl Borris), which was based at Handrup, to the north-west of Osnabruck. This unit received its aircraft in October 1944. JG 2 ‘Richtofen’ and JG 301 in the Reich Defence also got the D-9.

JG 26’s first known mission with the D-9 came on 3 December when some made up part of a larger formation that intercepted an RAF formation. The type was then seen in slowly increasing numbers. The first combat loss came on 18 December when an aircraft from II./JG 26 was shot down.

III./JG 54 became operational as a standard fighter unit on 25 December 1944. Although the D-9 was an excellent fighter, it was facing vastly larger numbers of high quality allied fighters, generally flown by better trained pilots (by this point many German fighter units were made up of a small group of surviving ‘experts’ and larger numbers of poorly trained novices). On 27 December the group lost four aircraft in a clash with Tempests from No.486 Squadron, only claiming one victory. On 29 December the group suffered its worst day, during an operation against low flying Allied aircraft. The group was ordered to patrol over a wide area in small numbers, and lost six pilots in an initial clash with Spitfires from No.411 Squadron and a total nine during the day, including Weiss.

![]() Focke Wulf Fw 190D from the front

Focke Wulf Fw 190D from the front

JG 54, JG 25, JG 2 and JG 301 all used the type in Operation Bodenplatt, mass attack on Allied fighter airfields in Holland, Belgium and northern France, which inflicted near fatal damage on the German fighter wings, which couldn’t afford the heavy losses suffered on the day. Although the operation did destroy a large number of Allied fighters, most of them were on the ground, and could easily be replaced, while their pilots survived.

During 1945 almost all available fuel went to the jet fighters. A standard example of the impact of this on piston engines units is JG 6 ‘Horst Wessel’ under Major Gerhard Barkhorn, which had 150 new D-9s from a nearby FW factory in April 1945, but could only patrol with four of them due to lack of fuel!

In the last few months of the war individual experts were able to make great use of their D-9s, but their units continued to suffer heavy losses. The D-9 might have been an excellent fighter, but it arrived far too late to have any real impact on the war in the air.

By April 1945 the D-9 was in use with Stab, I, II and III./JG 2, Stab and IV (Sturm)./JG 3, Stab and II.(Sturm)./JG 4, Stab, I and II./ JG 6, Stab, I, II and IV./JG 26 and I and II./JG 301.

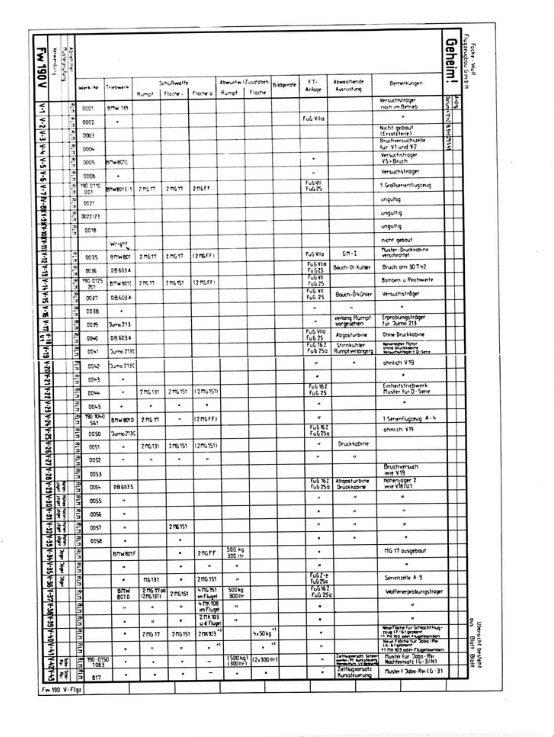

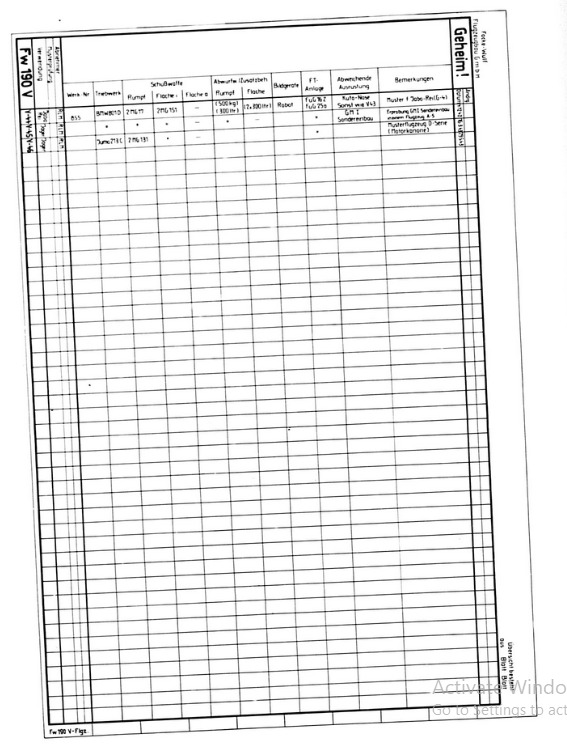

Prototypes

A series of prototypes were produced by modifying the airframes of Fw 190A-0 pre-production aircraft.

Fw 190 V 17 (W.Nr.0039)

This was the first prototype, and was converted from a standard A-0 over the winter of 1941-42. It flew with a Jumo engine by the end of 1942. This aircraft was later used as the prototype for the Fw 190 D-9 production model, and re-designated as the Fw 190 V 17/U1. A Jumo 213A-2 was installed at Adelheide in the spring of 1944, and the aircraft made its maiden flight in this configuration in May 1944 from Langenhagen. As V 17U/U1 it used a 1,776hp Junkers Jumo 213 A-1 engine with MW-50 water-methanol injection to raise power to 2,240hp and give a top boosted speed of 426 mph

Fw 190 V19

This was an engine test bed for the Fw 190 Ra-1 study. It got a Jumo 213 and became Fw 190 Wb-1 (Weiterentwicklungsbau 1 or Development construction 1), but was then destroyed in a crash on 16 February 1944 before other engines could be tested.

Fw 190 V20 (W.Nr.0042 TI+IG)

V20 was allocated to the Jumo 213 tests, but was destroyed in the August 1944 raid while getting a DBV 603L engine.

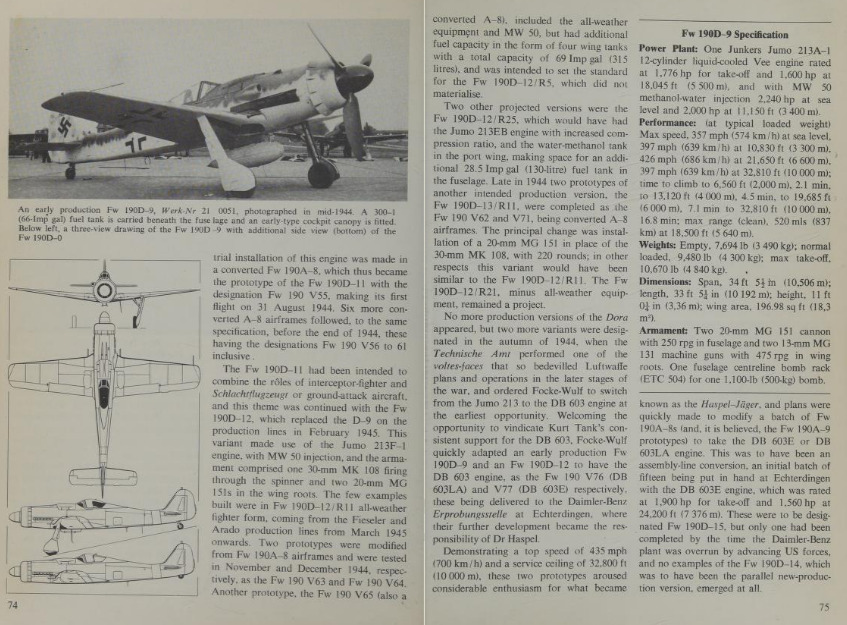

Fw 190 V21

V21 was allocated to Jumo 213 tests

Fw 190 V22

Fw 190 V23

Fw 190 V25

V25 was allocated to Jumo 213 tests

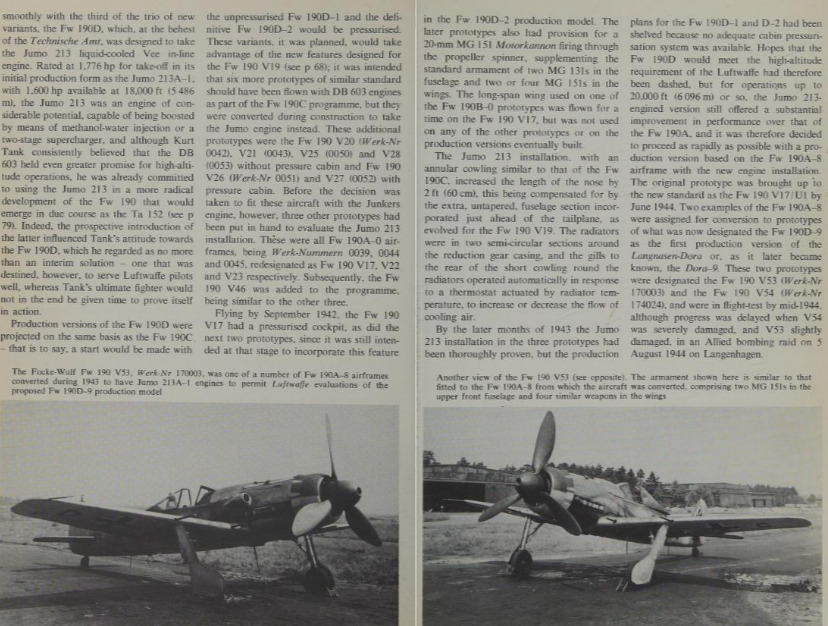

Fw 190 V53 (W.Nr.170003)

V53 was the first production prototype for the D-9. It carried two 13mm MG 131 machine guns and four 20mm MG 151 cannon. It made its maiden flight by June 1944. V53 was destroyed when the USAAF bombed Langenhagen on 5 August 1944.

Fw 190 V54 (W.Nr.174024)

V54 was the second production and third prototype for the D-9. It made its maiden flight by July 1944. It was armed with two 13mm machine guns and two 20mm cannon. V54 was destroyed when the USAAF bombed Langenhagen on 5 August 1944.

Fw 190D-1

The Fw 190D-1 was the original designation for a version of the aircraft to be powered by a Jumo 213 engine, with an unpressurised cockpit. Two prototypes were allocated to the project, V22 and V23, but after the D-1 was cancelled so were the two prototypes.

Fw 190D-2

The Fw 190D-2 was the original designation for a version of the aircraft to be powered by a Jumo 213 engine, with a pressurised cockpit. Two prototypes were allocated to the project, V26 and V27, but after the D-1 was cancelled so were the two prototypes.

Fw 190D-9

The D-9 combined the A-8 fuselage and wings with the Jumo 213A-1 engine. The first production aircraft were completed at Focke-Wulf’s factory at Sorau in Silesia in late August 1944. Problems with engine meant that the second aircraft wasn’t completed until mid-September, but construction soon sped up. By the end of September production was underway at Focke-Wulf’s factory at Cottbus, and in October work began at Roland (WFG) at Nordenahm and Fieseler at Kassel. Junkers and Siebel produced parts, and Arados was also involved in the programme. The total number produced is unclear, with at least 670 known and no records for December 1944 or February 1945 to the end of the war. 1,500 serial numbers are known to have been allocated to the D-9, but that doesn’t mean that all of these aircraft were completed.

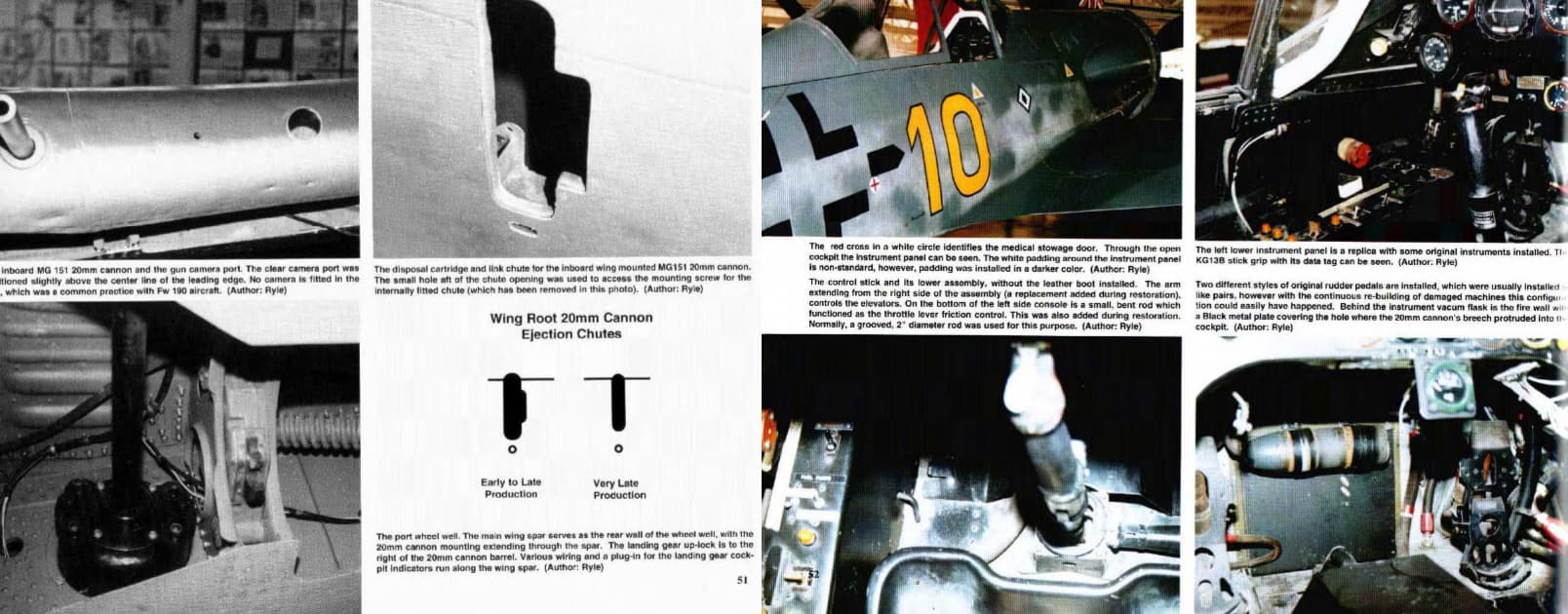

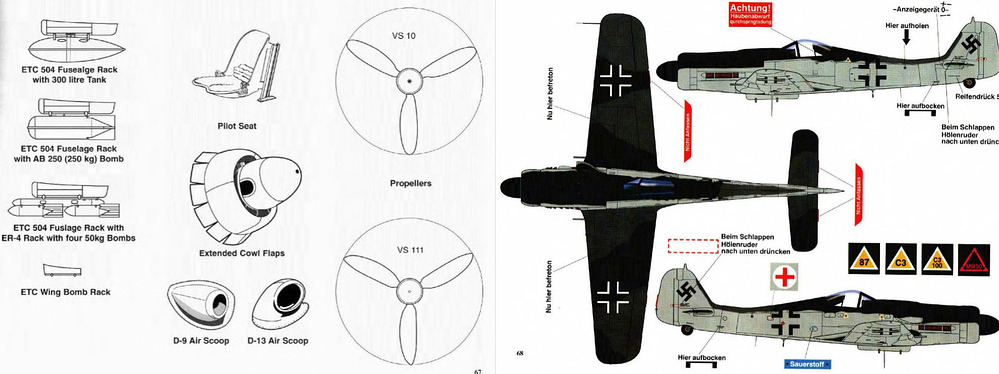

The standard D-9 was armed with two 13mm MG 131 machine guns above the engine and two 20mm MG 151 cannon in the wing roots. It could also carry an ETC 501 or ETC 504 stores carriers below the fuselage.

The D-9 entered service with III./JG 54 as soon as the first aircraft were available in September 1944. 12./JG 54 was given the task of protecting the Me 262s of Kommando Nowotny when they were landing or taking off and were at their most vulnerable.

Very few of the early aircraft were equipped with the MW 50 injection equipment. The first D-9 unit, III./JG 54, began to convert to the type in September 1944, and by the end of October had 68 aircraft, of which only one had the MW 50 installed. However 53 had been given a new Junkers kit that increased the manifold pressure in the engine and boosted power from 1,750hp to around 1,870hp.

By the end of December 1944 there were 183 D-9s in service with three units (III./JG 54, II./JG 267 and III./JG 26), with some equipped with both the MW 50 and Junkers kits, some with one or the other and some without either. However new aircraft coming off the production line mainly had both.

Early in 1945 the D-9 was issued to JG 2, JG 3, JG 6, JG 51 and JG 301, although these units normally operated a mix of types. In service the D-9 was considered to be as good as its main opponents (in particular the Merlin powered P-51 Mustangs and the Griffon powered Spitfire Mk.XIV. It handled better than the Fw 190A, was faster and climbed quicker. It could out-turn most Soviet fighters at the normal combat levels, and was quicker in the dive than the Yak-3 or Yak-9.

Fw 190D-9/R1

The D-9/R1 carried an extra pair of 20mm MG 151 cannons in the outer wing positions.

Fw 190D-9/R2

The D-9/R2 removed the machine guns above the engine but added 30mm MK 108 cannon in the outer wings.

Fw 190D-9/R5

The D-9/R3 was a fighter bomber version, with extra fuel in the wings and two ETC 50 or ETC 71 bomb racks below each wing, allowing the aircraft to carry for SC50 bombs.

Fw 190D-9/R6

The D-9/R6 was the standard kit that allowed the W.Gr 21 rocket to be carried below the wings, for use against American bomber formations.

Fw 190D-9/R11

All weather fighter with FuG125 radio, PKS 12 directional controls and standard FuG 16 Za and FuG 25a controls.

Fw 190D-9/R14

The R14 was given an ETC 504 bomb rack under the fuselage, capable of taking one LT 1b torpedo or two BT 1400 bomb-torpedoes.

Fw 190D-9/R20

The R20 was given a high pressure MW50 power boost system. This later became a standard fitting.

Fw 190D-10

The D-10 was an up-armed version of the aircraft. The MG 131 machine guns were removed, and a single 20mm MG 151 cannon carried in their place. It was also hoped to mount a 30mm MK 108 firing through the engine spinner, but this didn’t work. The type never entered production, although it is possible that two D-9s were converted to the D-10 standard.

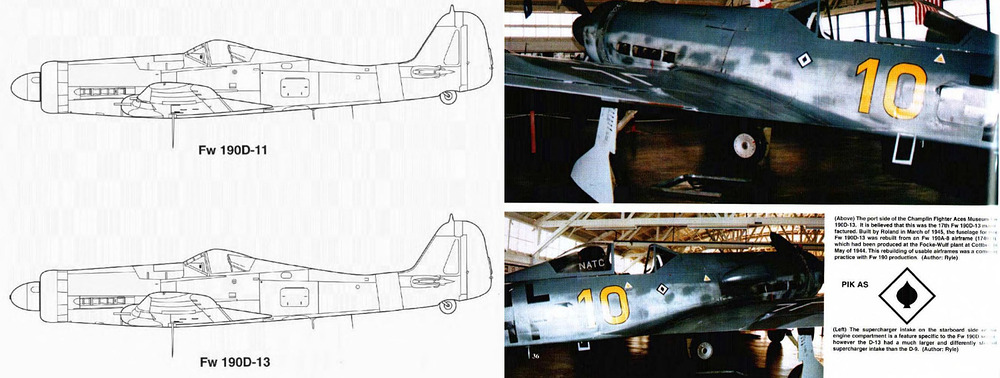

Fw 190D-11

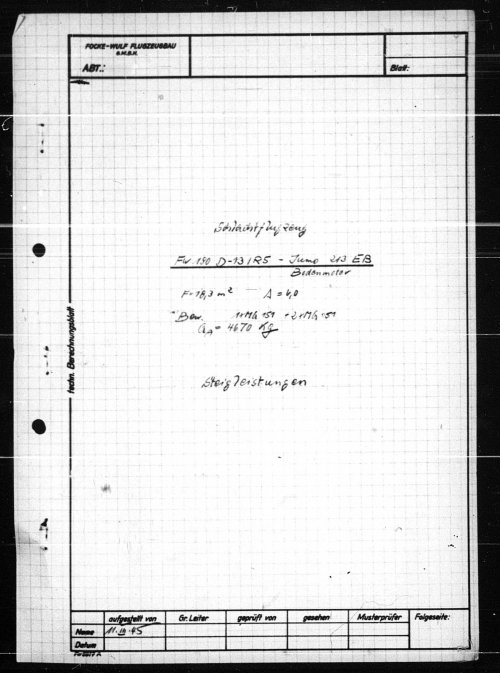

The Fw 190D-11 was a very heavily armed version, armed with two 20mm MG 151 cannon in the wing roots and two 30mm MK 108 cannon in the outer wing positions. It was powered by the Jumo 213F engine which had a three stage turbo-supercharger, and used the MW50 injection system.

Seven prototypes of the D-11 were produced, possibly followed by at least 17 production aircraft completed in March 1945 by converting A-8s.

V55 (W.Nr.170923) was the first prototype. It had a Jumo 213F engine, two 13mm MG 131 machine guns and two 20mm MG 151/20 cannon.

V56 (W.Nr.170924) had the MG 131s removed and the wing mounted MK 108 cannon added. All further prototypes apart from V60 carried these guns.

V 57 (W.Nr.170926) was rebuilt from a Fw 190A-8.

V 58 (W.Nr.170933) was similar to V 57.

V 59 (W.Nr.350156) was similar to V 57 and V 58.

V 60 (W.Nr.350157) was an unarmed prototype.

V 61 (W.Nr.350158) was delivered to Junkers for engine trials.

A number of R kits were designed for the D-11, but there is no agreement on what they were, and it is unlikely that any were used.

R5 was either a TSA 2D bomb aiming device combined with eight 50kg bombs (presumably two under each wing and four under the fuselage) or extra fuel.

R11 was the bad-weather kit, including the FuG 125 D/F radio.

R20 combined was either the PKS 12 radio, or the Jumo 213F-1 engine.

R21 was the all-weather with the F-1 engine.

R25 is an alternative code for extra fuel.

The D-11 turned out to be rather too heavy for its tyres, and was followed by two lighter versions.

Fw 190D-12

The Fw 190D-12 was armed with one 30mm MK 108 in the engine and two 20mm MG 151 in the wing roots. Three prototypes were produced by converting A-8s (V 63 (W.Nr.350165), V 64 (W.Nr.350166) and V 65 (W.Nr.350167)). The D-12 was to be produced at Arado and Fieseler, starting in March 1945. Production was delayed when Allied bombing destroyed the factory producing the Mk 108 cannon.

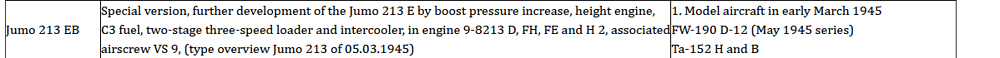

As with the D-11, there is no agreement on the details of the R kits. R5 was either extra fuel or a ground attack version. R11 was an all-weather version. R14 was to carry a torpedo. R21 was either a ground attack version or the all-weather version with a Jumo 213F-1 engine. R25 was was to use the Jumo 213EB engine, which added 200hp to its power, and was expected to give a top speed of 478mph at 31,000ft.

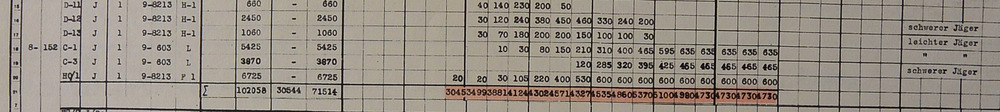

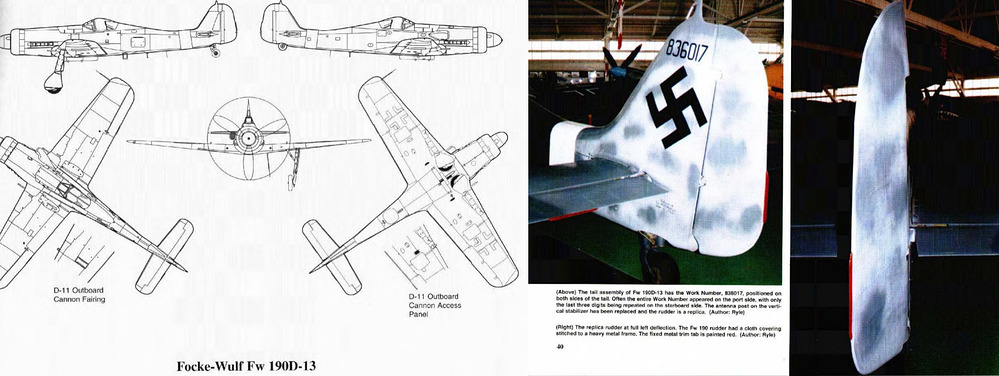

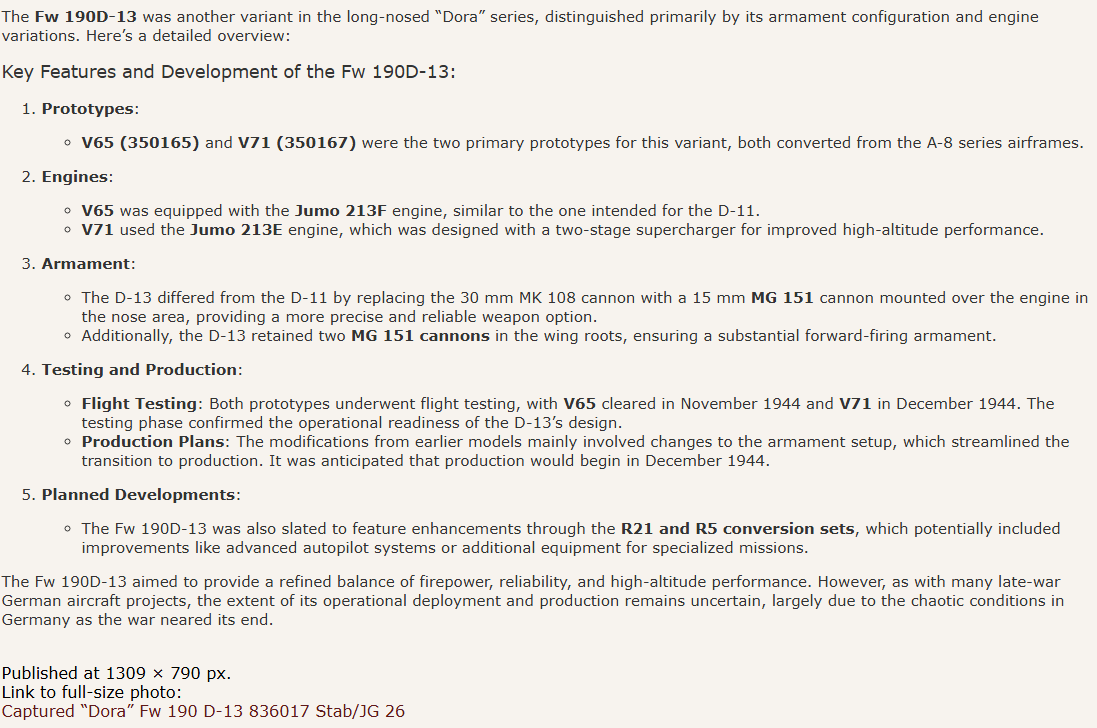

Fw 190D-13

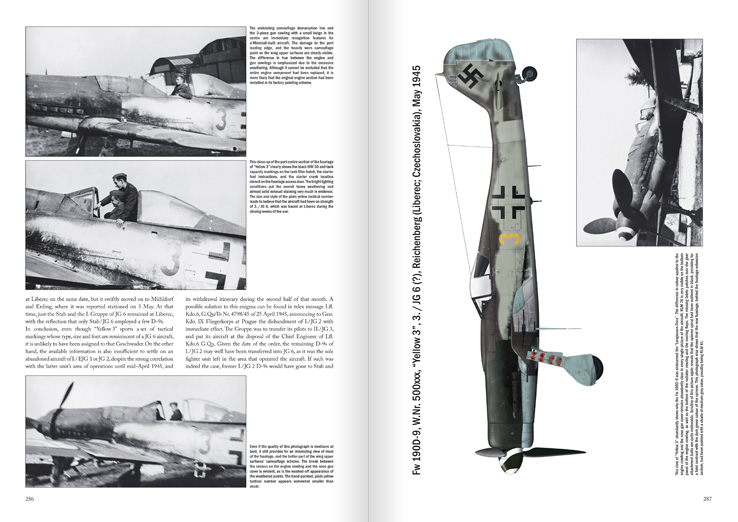

The Fw 190D-13 was armed with three 20mm MG 151 cannon – one in the engine and two in the wing roots. Two prototypes were produced - V 62 (W.Nr.732053) and V 71 (W.Nr.732054), both converted from Fw 190A-8s. The D-13 was to have entered production at Arbeitgemeinschaft Roland in March 1945. The D-13 used the same R kits as the D-12, but with the same disagreements over what they actually were. It is possible that a number of D-13/R11s were completed at Roland and delivered to JG 26.

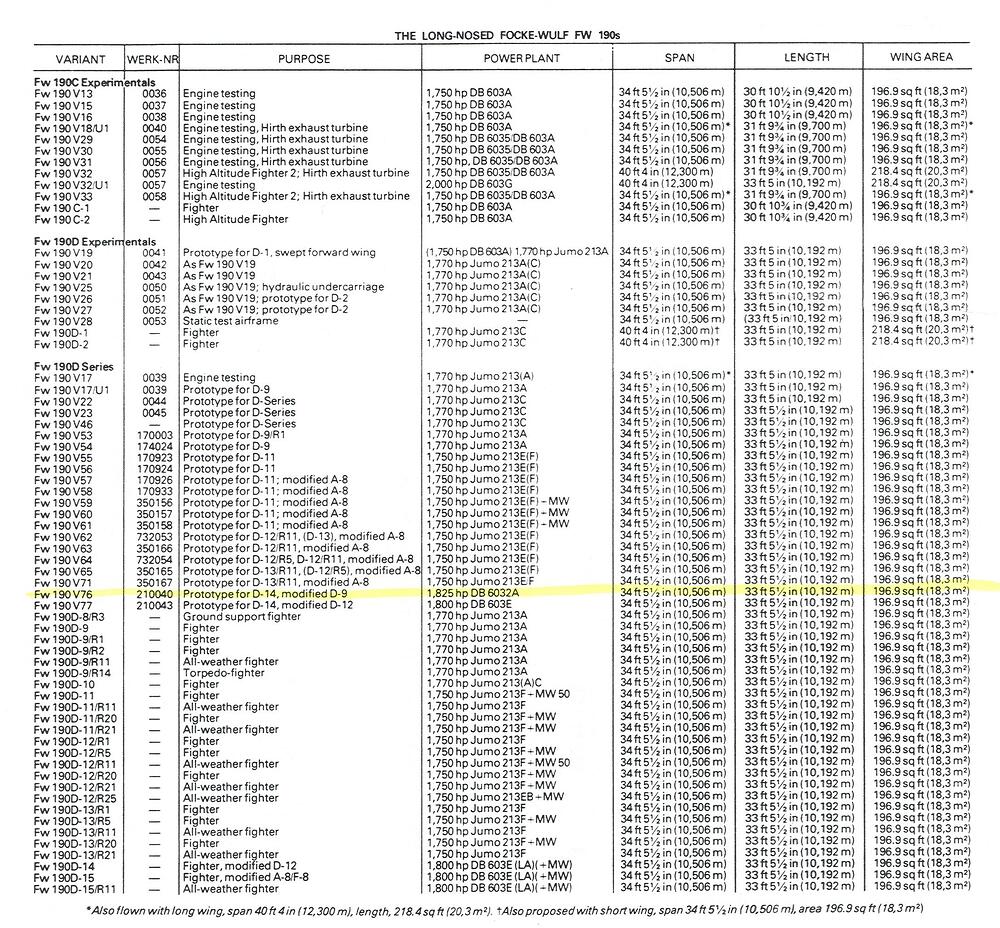

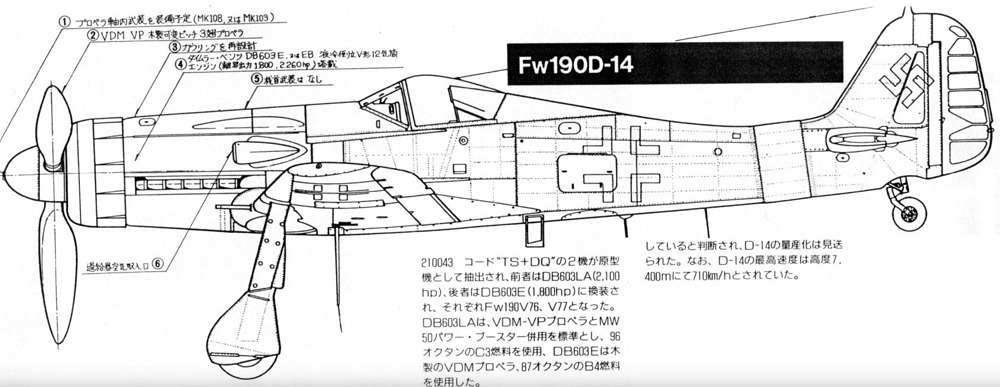

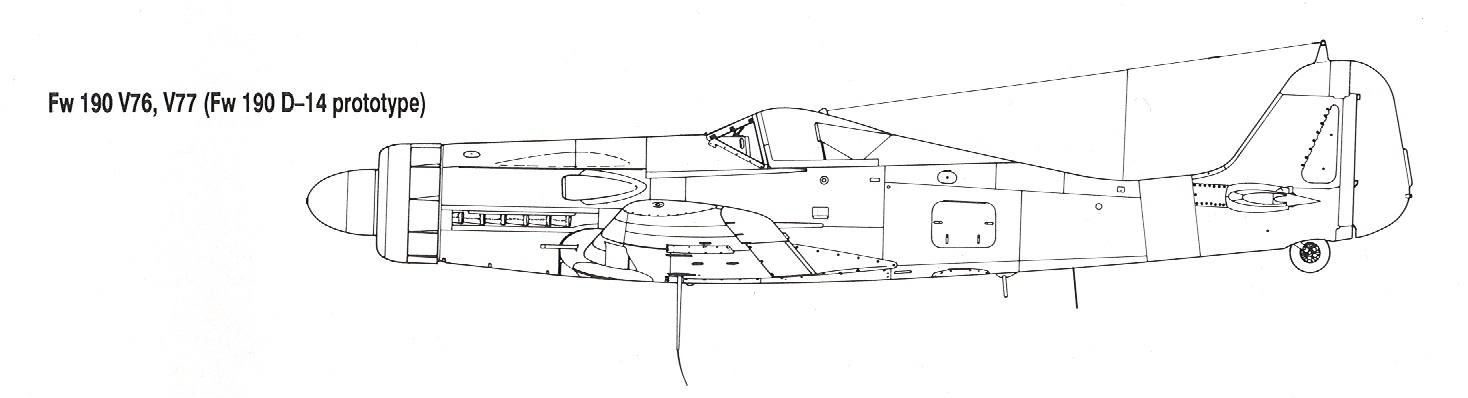

Fw 190D-14

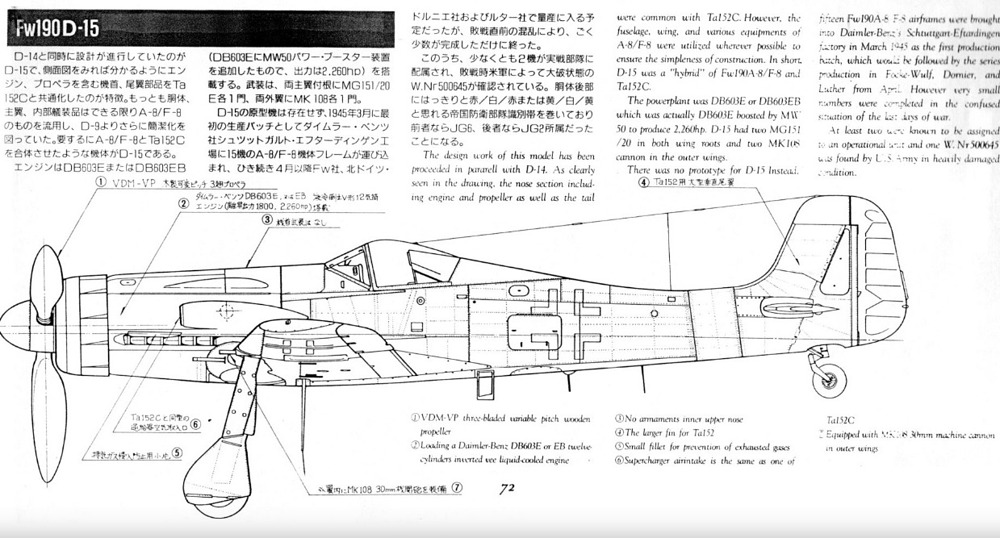

The Fw 190D-14 was the first attempt to mount a 1,750hp Daimler-Benz DB 603 engine in the Fw 190D, after the failure of the Fw 190C in 1943. It was based on the D-12, although the two prototypes had to be converted from D-9s. V76 (W.Nr.210040) made its maiden flight on 20 November 1944 with the DB 603 engine. V77 (W.Nr.210043) was completed with the Jumo 213 for comparative tests, in which the DB 603 was found to be the better engine at all altitudes. The D-14 programme was cancelled on 31 January 1945 in favour of the D-15.

Fw 190D-15

The Fw 190D-15 replaced the D-14 on 31 January 1945. It was to be a basic conversion of the Fw 190A-8 or A-9, with the DB 603 engine and longer tail. One prototype may have been completed before the end of the war.

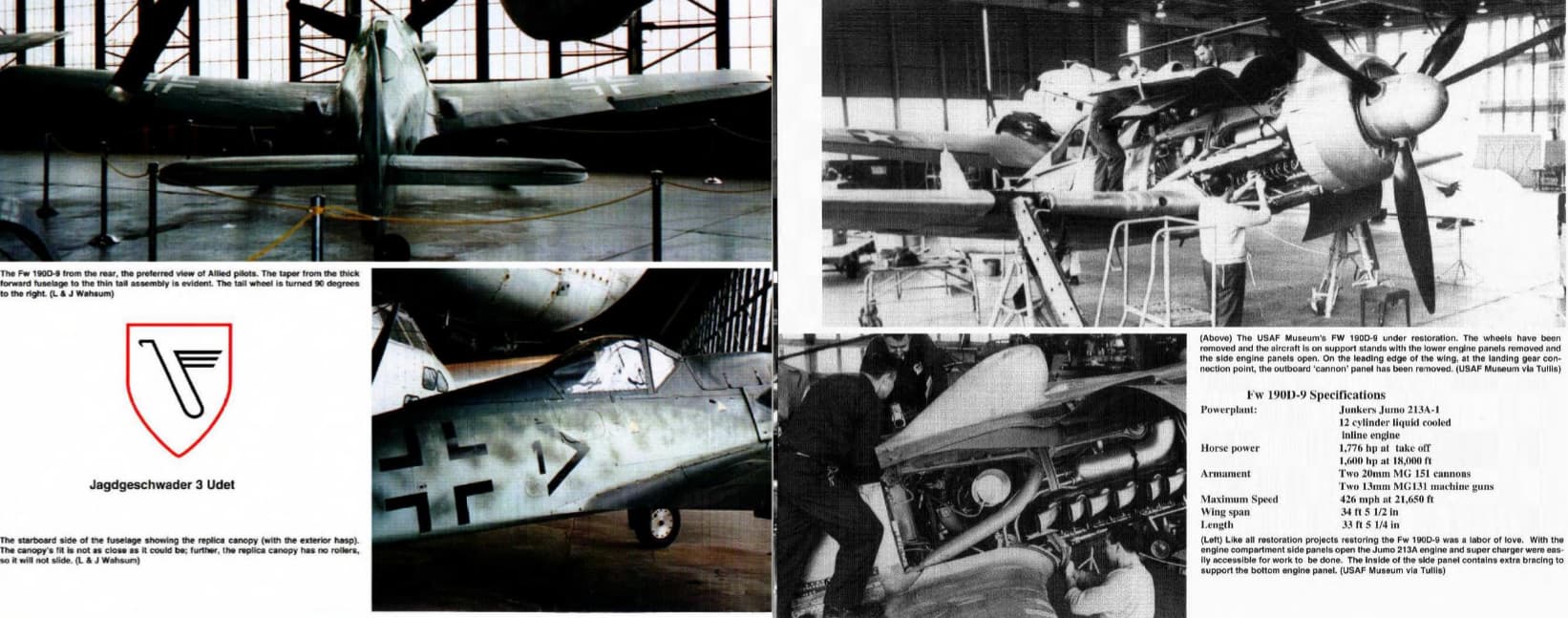

Fw 190D-9

Engine: Junkers Jumo 213A-1 12-cylinder inverted V

Power: 1,776hp (normal take off), 1,200hp (continuous running), 2,240hp (boosted)

Crew: 1

Span: 34ft 5.5in

Length: 33ft 5.5in

Height: 11ft 0in

Empty weight: 7,694lb

Loaded weight: 9,480lb

Maximum take-off weight: 10,670lb

Max speed (boosted): 357mph at sea level, 397mph at 10,820ft, 426mph at 21,655ft, 397mph at 32,810ft

Climb Rate: 7min 6sec to 19,865ft (6,000m)

Service ceiling: 39,370ft (12,000m)

Endurance:

Range: 519 miles at 18,500ft

Armament: Two 13mm MG 131 machine guns above engine and two 20mm MG 151/20 cannon in wings

Bomb load: One 1,102lb/ 500kg SC500 bomb

Book

Fw 190D-9: Defence of the Reich 1944–45 (Dogfight)

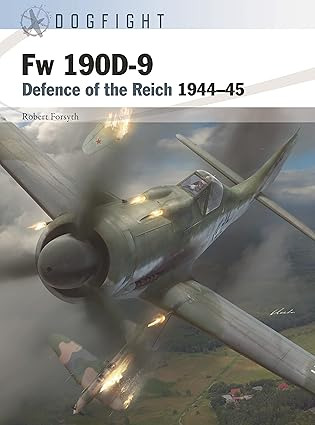

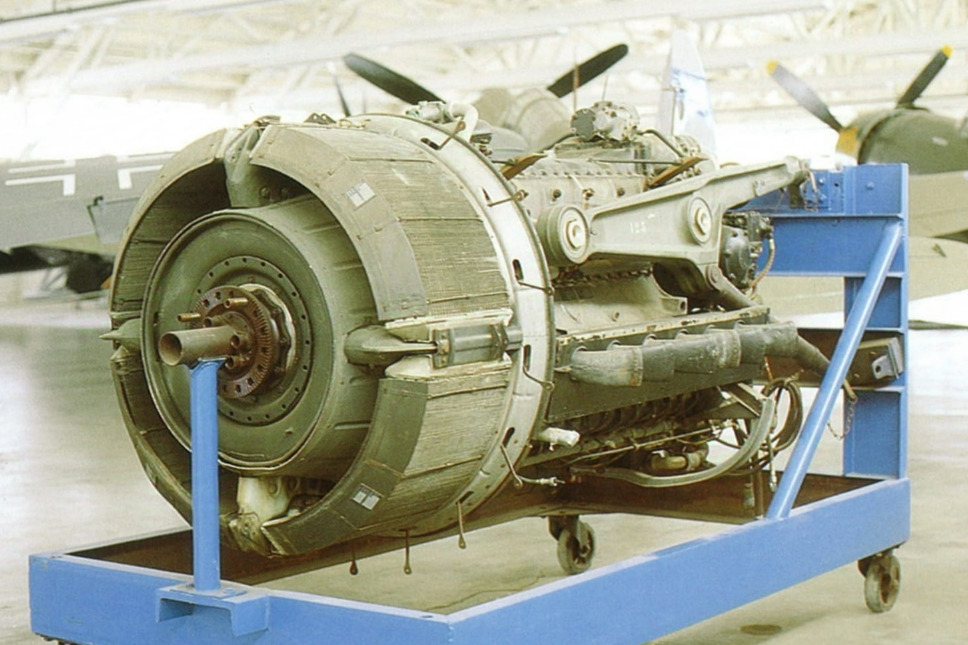

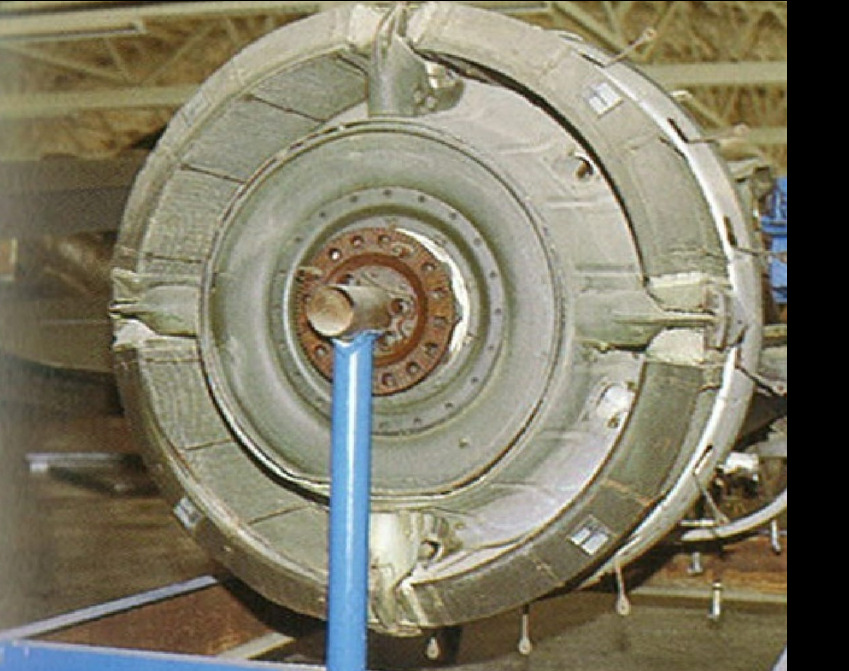

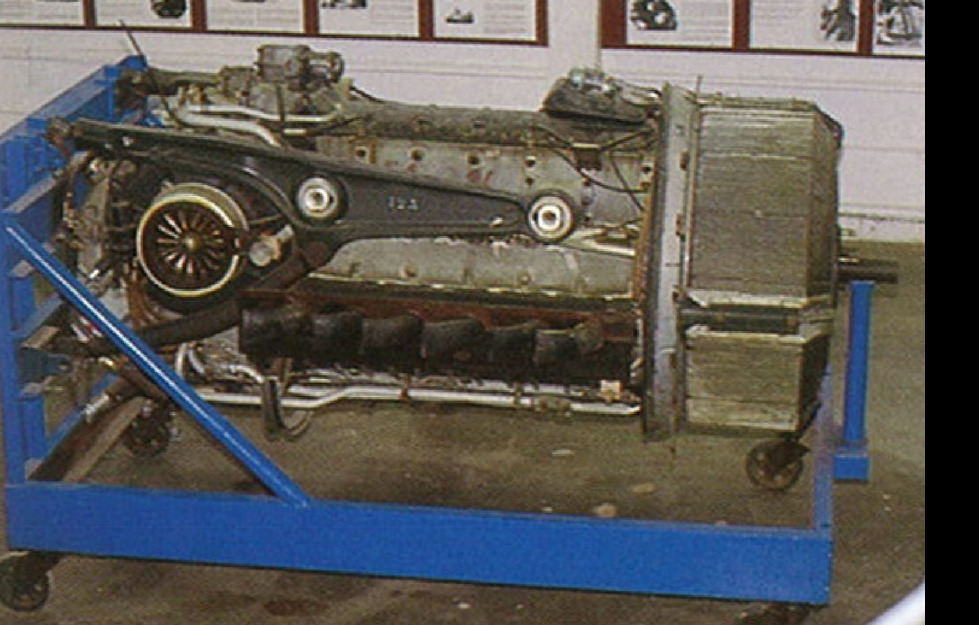

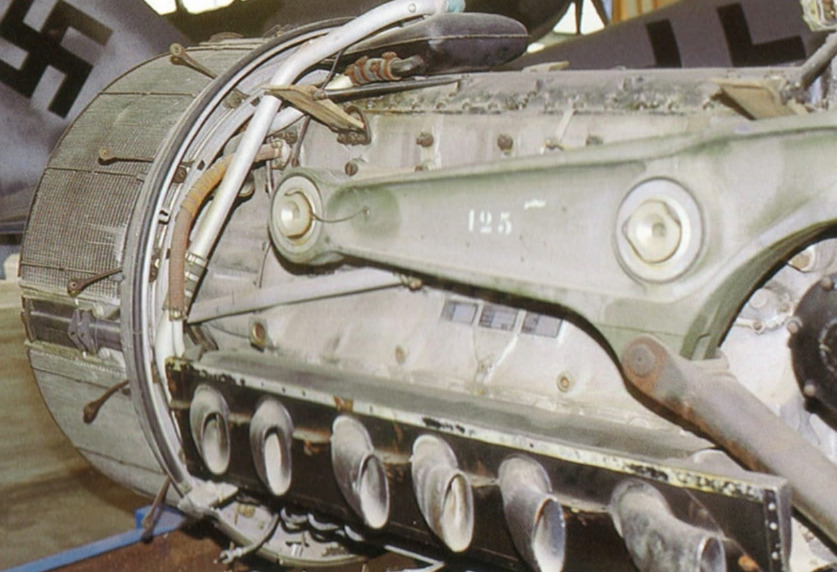

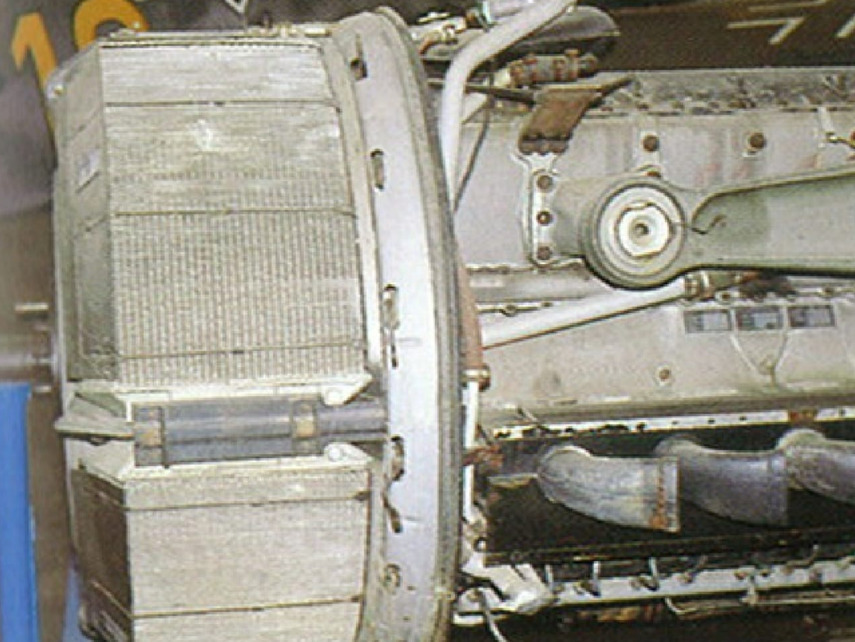

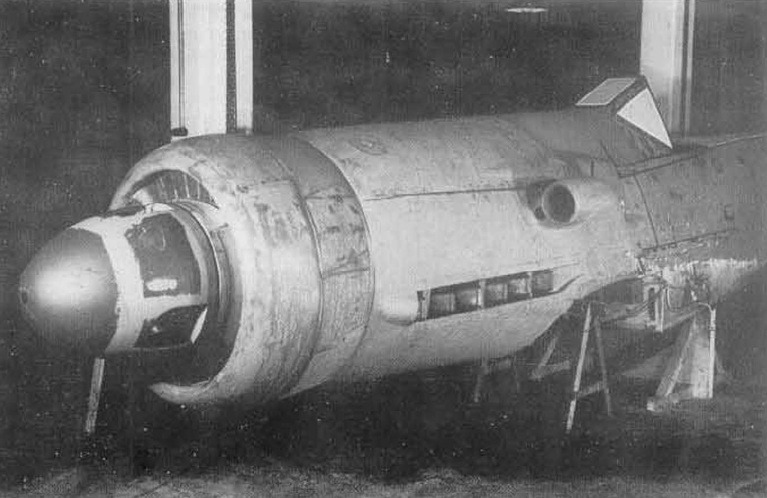

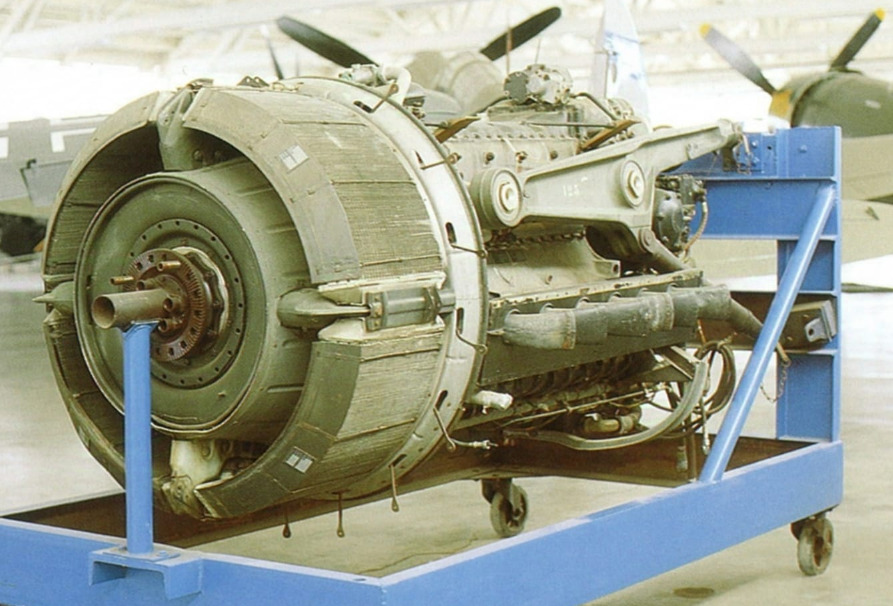

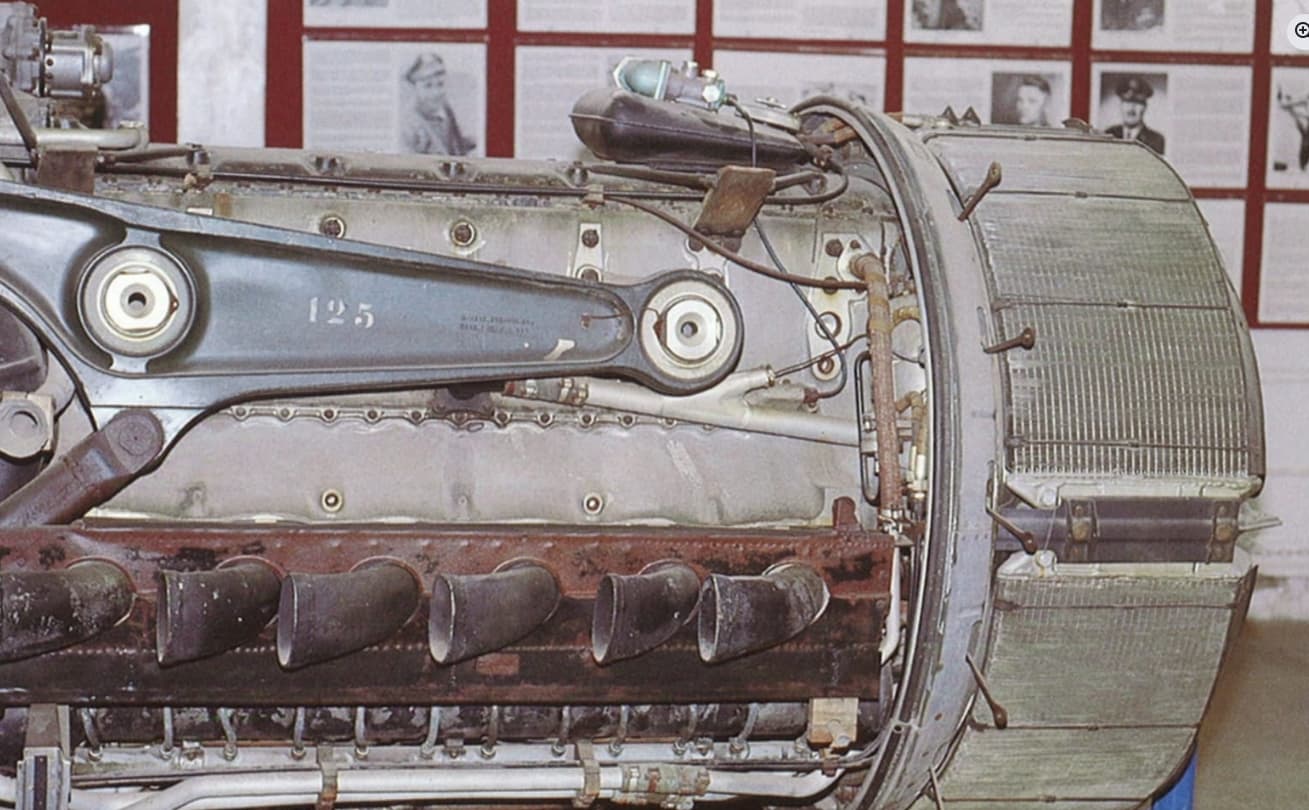

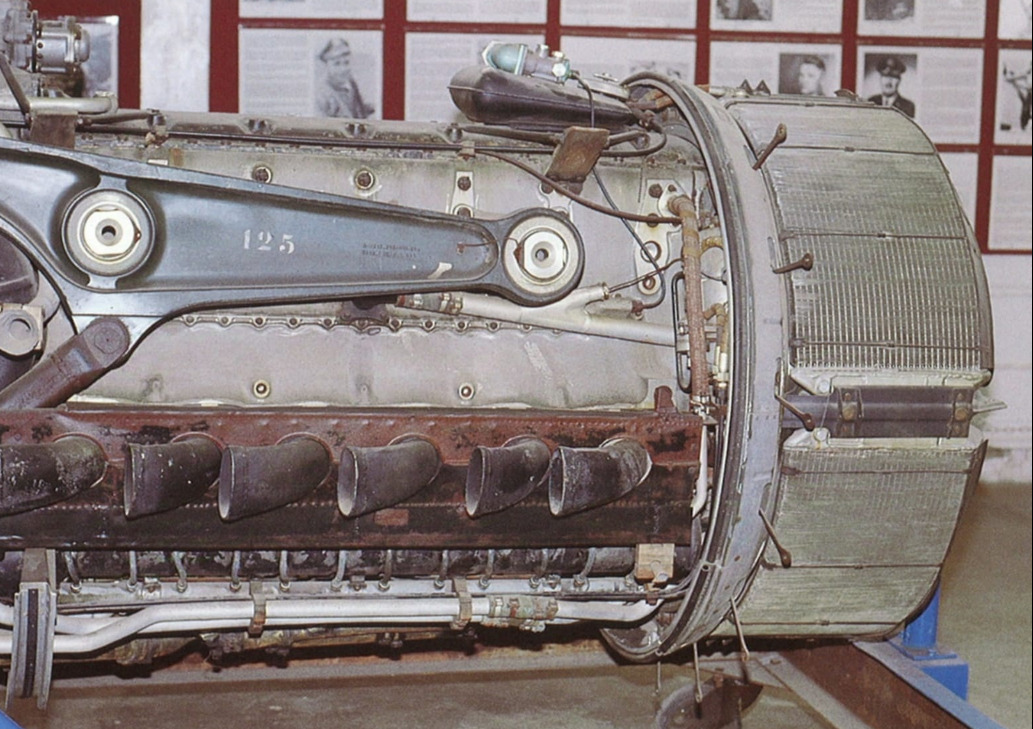

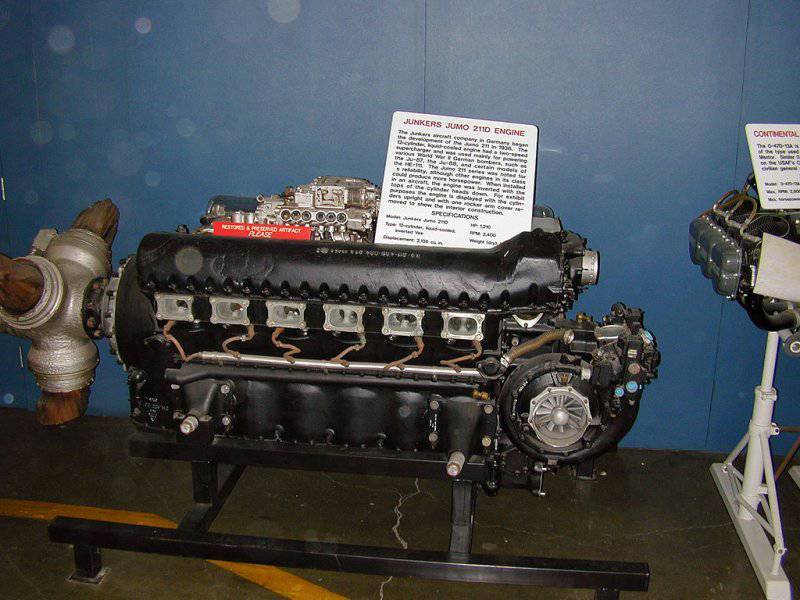

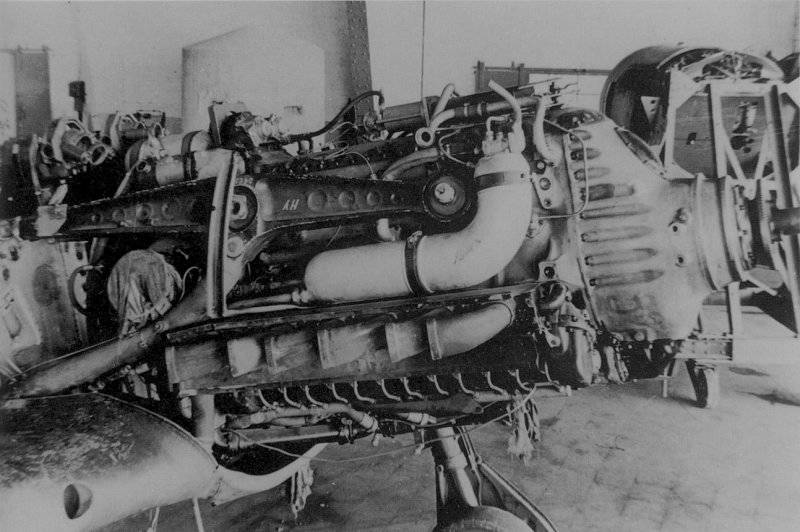

Really life images of engines Fw 190 D13 / D14 / engine types images

that’s Fw 190 D14

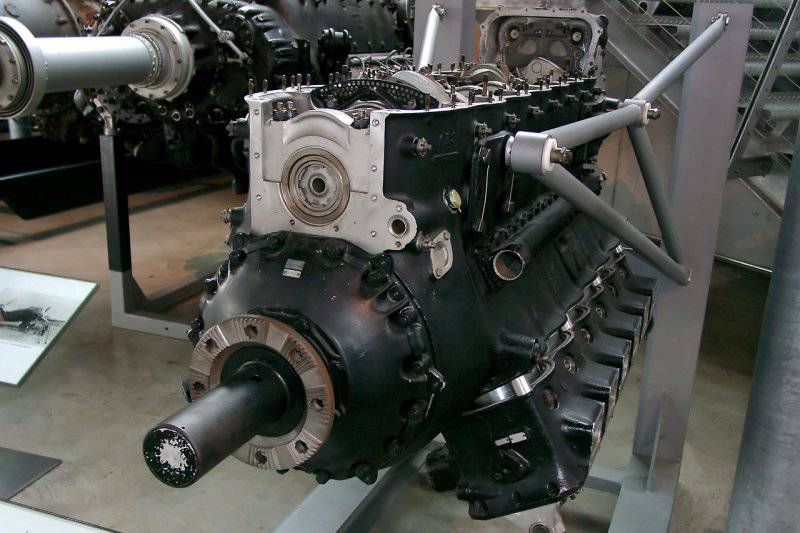

The military has constantly strived and is striving to obtain higher flight characteristics of aircraft. The main way to achieve success in this direction is the development and use of aircraft power plants of greater power. To simplify development and reduce the time for design and organization of production, designers and manufacturers of aircraft engines rely on previously developed and well-proven designs. This approach was also used in the creation of the Jumo-213 engine, for which its predecessor Jumo-211 was used as the initial base. The dimensions of the engine and the V-shaped arrangement of 12 cylinders have not changed. The working volume has also remained the same - 35 liters. Improvements that concerned the increase in possible thermal, kinematic and mechanical loads of engine parts, an increase in maximum speed, the development of superchargers of greater performance and some other improvements made it possible to increase the power of the Jumo-213 engine by 25% in comparison with the Jumo-211.

Jumo-211

The general management of the development of the Jumo-213 engine was carried out by Dr. Lichte. Dr. Lichte was in charge of both the development of the engine and its achievement to the required level of reliability, as well as the organization of serial production after the first “A” variant ready for series production. The head of the work, Dr. Lichte, said: “Initially, the Jumo-213 was designed to achieve maximum mechanical and thermal loads and represented the highest stage in the development of four-stroke internal combustion engines that operated according to the Otto cycle.” This statement characterizes the engine as a very serious achievement in the field of aircraft engine building. The first pre-production version of the engine in mid-1942 developed a power of 1750 hp (1285 kW) at 3250 rpm. This figure was 30% higher than the power of the serial Jumo-211F engine, produced at that time. At the same time, in comparison with the Jumo-211F, the new engine had a lower specific fuel consumption. There are no documents about earlier tests of the Jumo-213 engine.

The first ideas for the development of a 35-liter aircraft engine with increased power appeared in the fall of 1936 - winter of 1937, after the start of tests of the Jumo-211 engine. It was planned to begin testing the Jumo-213 in the spring of 1938, after designing, finalizing and assembling the first prototypes. An RLM document dated June 21, 1939 states that tests of the Jumo-213 prototype engines began in August 1938. In another document dated November 4, 1939, compiled following a meeting of representatives of Jumo and RLM, it is reported that during the tests of this engine on test benches (carried out during the year), the Jumo-213 managed to develop a power of 1500 hp. Although somewhat lower than expected. In this regard, it was necessary to refine the gas exchange process and fuel injection systems.

Jumo-213

From the above, it follows that bench tests of the Jumo-213 engine were carried out with problems, and the elimination of the problems that arose took a lot of time, which was sorely lacking during the war years. However, in January 1940, despite the problems, the Ju-52 was prepared for flight tests of the Jumo-213, which had reduced power. Based on the results of these tests, a detailed report on the engine was drawn up. It was planned to produce 30 Jumo-213 engines of the zero series. Optimistic plans for the engine could not be implemented in practice so quickly, since during bench tests, new problems arose, the elimination of which took time. As mentioned above, in principle, the Jumo-213 differed little from its predecessor Jumo-211. This mainly concerned the engine block and the location of the cylinders. In accordance with the requirements of the increase in power and the experience gained during the work, the prototype received some improvements in terms of design and operation. New developments and the most important changes used in the Jumo-213 engine were:

Water-cooled cylinder heads; adjustment of the gas distribution mechanism; 1 exhaust valve and 2 intake valves for each cylinder; injection of special mixtures that provide additional cooling of the cylinders and removal of heat from them.

Camshafts of a new type, which rested on 7 main journals; counterweights at both ends of the camshafts; ball bearings; additional shaft for power take-off to the fuel pump.

A new type of crankshaft with 7 main journals and one additional front pulley to meet the requirements of achieving maximum speed; power take-off for the drive of mechanisms in the rear of the crankshaft; counterweights; At the front is a reduction gearbox for the propeller.

Controllable pitch propeller having a pressurized lubrication system through a hollow shaft; In the front part of the engine block there are special bearings that take axial and radial loads and the rear pulley.

Use of high-altitude DVL superchargers in single-stage and two-stage versions with two and three speeds, as well as adjustable position of the blades at the inlet of the supercharger; increase in the pressure of the injected air by 50% at different altitudes (up to 10 km).

Fuel injection system, made in the form of a double pump that supplies fuel from the tanks; high-pressure fuel pump; spiral air filter; fuel consumption sensor; use of high-pressure fuel pump injectors; the possibility of using ordinary aviation gasoline B4 (octane number 87) or special C2 in short supply for Germany (obtained by distillation of oil) and synthetic C3 with an octane number of 95-100.

Double-circuit pressure cooling system (maximum operating coolant temperature 120 °C).

Pressurized lubrication system using multiple gear pumps that supply and withdraw engine oil; centrifugal oil filter; main and additional oil flows; oil cooler; heat transfer with the cooling system.

Jumo 211

“Commandogeret” - a mechanical “computer” that regulated some parameters of the power plant; the fuel supply was regulated by the pilot; Engine speed, supercharger speed, boost pressure, ignition in the fuel-air mixture cylinders, propeller installation angle were adjusted automatically.

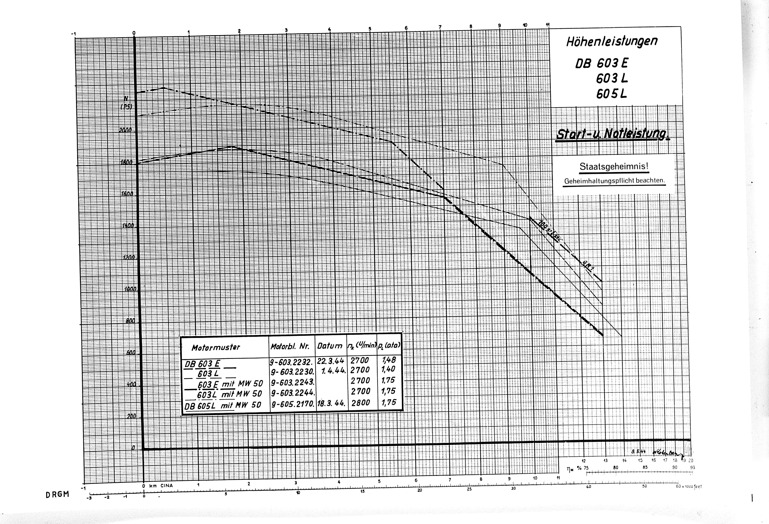

During the war, an increase in the power of the power plant was achieved by increasing the maximum engine speed, increasing its displacement, increasing the boost pressure, as well as due to more advanced internal or external cooling. The MW-50 system was used to improve internal cooling.

All these innovations were based on the high parameters of various engine processes and made it possible to obtain high performance of the Jumo-213 engine. Thus, closer to the end of World War II, another fairly advanced piston aircraft engine for that time was obtained. However, it took some time before it could be completed, and the date of the start of serial production was postponed several times. The director of engine production Jumo Cambeis explained to RLM the reasons for the postponement of the start of production each time. After 7 successful 100-hour engine tests, the JUMO and RLM were finally able to start mass production in October of 1942. For this purpose, under the direction of Dr. Lichte, a “large troupe of Jumo-213” was organized in Dessau, which for many weeks was engaged in such tests around the clock. However, during test flights of Fw-190 fighters equipped with Jumo-213, a powerful engine vibration appeared, transmitted to the body of the aircraft and preventing the pilot from observing the instruments and using the sight of the onboard weapons. The vibration was insignificant at first, but then, during the tests, when all the necessary equipment was mounted in the engine compartment, the vibration of the Jumo-213 increased significantly. After lengthy tests during numerous flights and some modifications, in the summer of 1943 it was possible to reduce vibration to a value that allowed the engine to be used on aircraft. For this, a new crankshaft was made. This again required time, and only in October 1943 it was possible to begin serial production of the Jumo-213 engine. Engine production was quite slow: only 74 engines were produced by the end of 1942. During 1943, monthly production was often 1-2 engines. And only in January 1944, 100 engines were produced. Already in March, the number of engines produced was more than 500 units.The

maximum production volume was reached in February 1945 - 994 units. The engine at launch developed about 3250 revolutions per minute. During climb and in combat mode, the speed was 3000 rpm. Economy mode of operation is 2100-2700 rpm. The maximum speed on takeoff of a more advanced version of the aircraft engine - Jumo-213J - was 3700 revolutions per minute. Climb and combat mode - 3400 rpm, economy mode - 3000 rpm. Long time spent on the development and organization of serial production (7 years!) of the engine Jumo-213 and a catastrophic shortage of the necessary materials did not make it possible to produce this engine in significant volumes at the end of the war. In addition, it was not possible to finalize more advanced versions of the Jumo-213 engine. The unfavorable development of events for Germany increasingly required fighters equipped with powerful engines, which were based on one version.

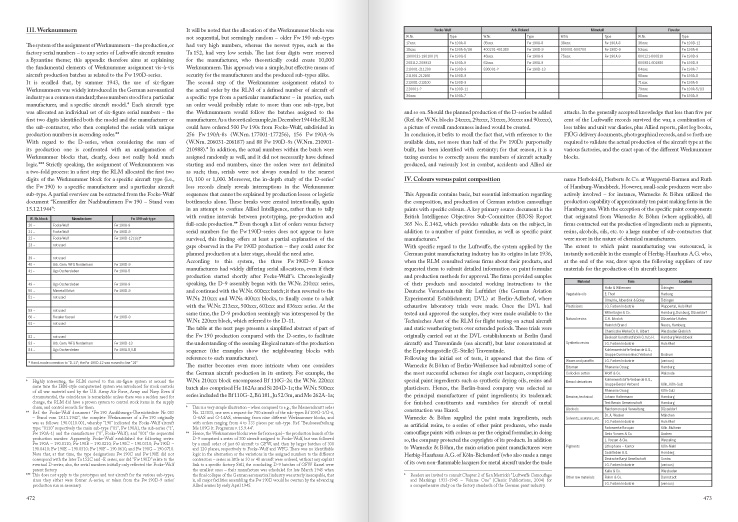

Main modifications and projects of the Jumo-213 engine:

Jumo-213A

A modification of the Jumo-213 engine, intended for installation on bombers. The Jumo-213A did not have the ability to install an automatic cannon in the camber of the cylinders. A pre-production batch of the Jumo-213 A modification was released in 1942. In August 1944, large-scale production began. Takeoff power was 1750 horsepower (1285 kW), altitude 5500 m. When equipped with the MW-50 system, the engine could develop 2100 hp (1540 kW) for 10 minutes. After that, the engine should run normally for at least five minutes. If the MW-50 system is turned on, the boost pressure is increased by 0.28 atmospheres. At an altitude of 5000 m, the power developed by the engine was 1900 hp (1395 kW). It was assumed that this modification would be installed on Ju-88 and Ju-188 bombers.

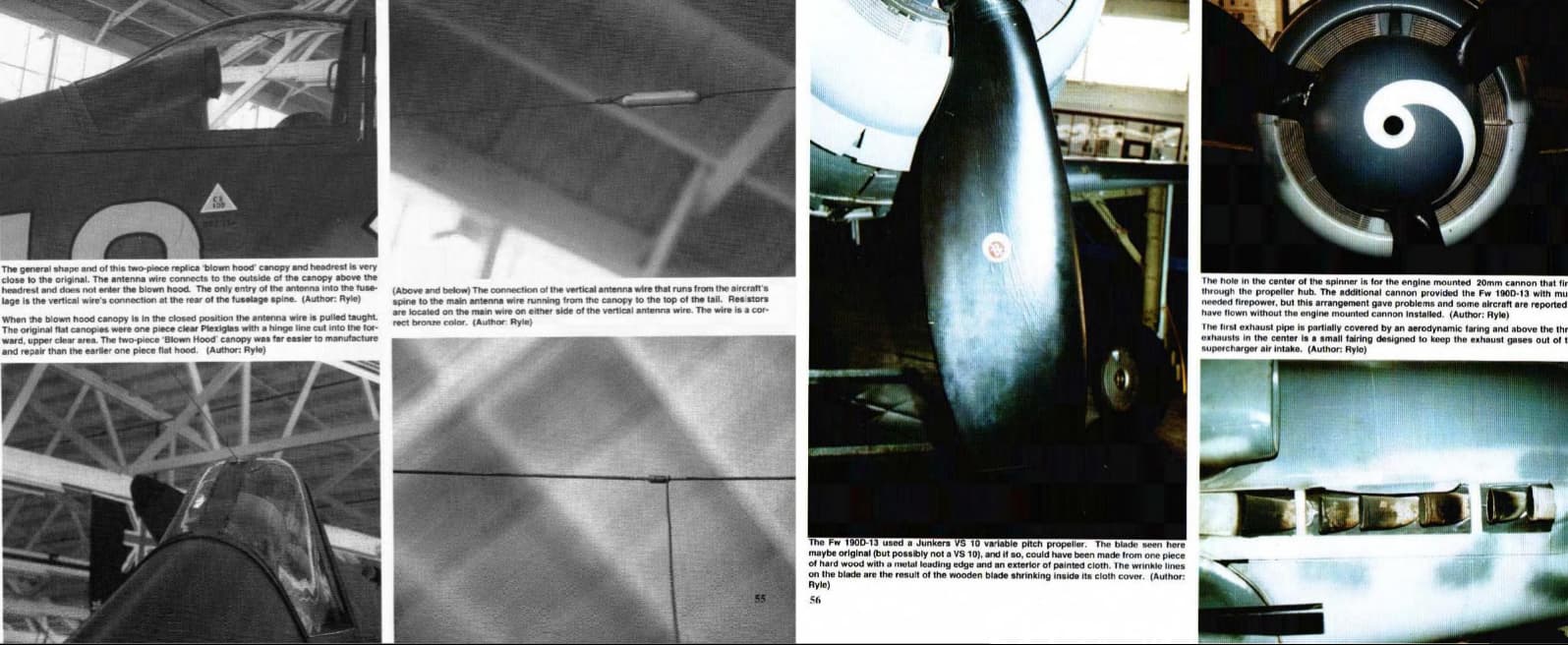

Jumo-213 AG

A variation of the Jumo-213A engine, equipped with a more efficient supercharger. The take-off power of the Jumo-213 AG engine is 1900 hp (1400 kW). This engine was installed on the FW-190 fighters of the D-9 series. The MW-50 system made it possible to increase the engine power to 2240 hp. for 10 minutes. At the same time, the altitude was reduced to 4750 m from 5500 m. With the GM-1 system at an altitude of 10000 m, the FW-190 of the D-9 series developed a speed of 700 km / h. This allowed the aircraft to successfully destroy high-altitude enemy fighters. This speed exceeded that of the FW-190 D-11, equipped with a high-altitude Jumo-213 F engine without the use of the GM-1 system. However, there was a significant drawback - 105 kg of GM-1 mixture placed on board provided only 15-17 minutes of flight. Jumo-213AG for FW-190 D-9 fighters was supplied to aircraft assembly plants complete with a Junkers VS 111 propeller, a radiator with armor, an engine frame, jet exhaust pipes, a coolant temperature regulator, a switchgear that was used to supply warm air for heating to the onboard armament, as well as sensors for measuring temperature and altitude. The version for twin-engine aircraft had some differences from the engine planned for single-engine fighters. This version was made as a “single power plant” and was interchangeable with the DB-603 power plant, which had slightly larger dimensions, but about the same weight. The Jumo-213 AG engine was additionally equipped with a warm air intake system used to heat the wings and cockpit, as well as a 3000-watt generator.

Jumo-213 V

Special modification with a higher compression ratio. The take-off power of this engine was 2000 hp (1470 kW). Jumo-213 B was developed for gasoline with an octane rating of 95 units. The engine passed bench tests, but due to an acute shortage of high-octane aviation fuel, serial production of this engine was not established.

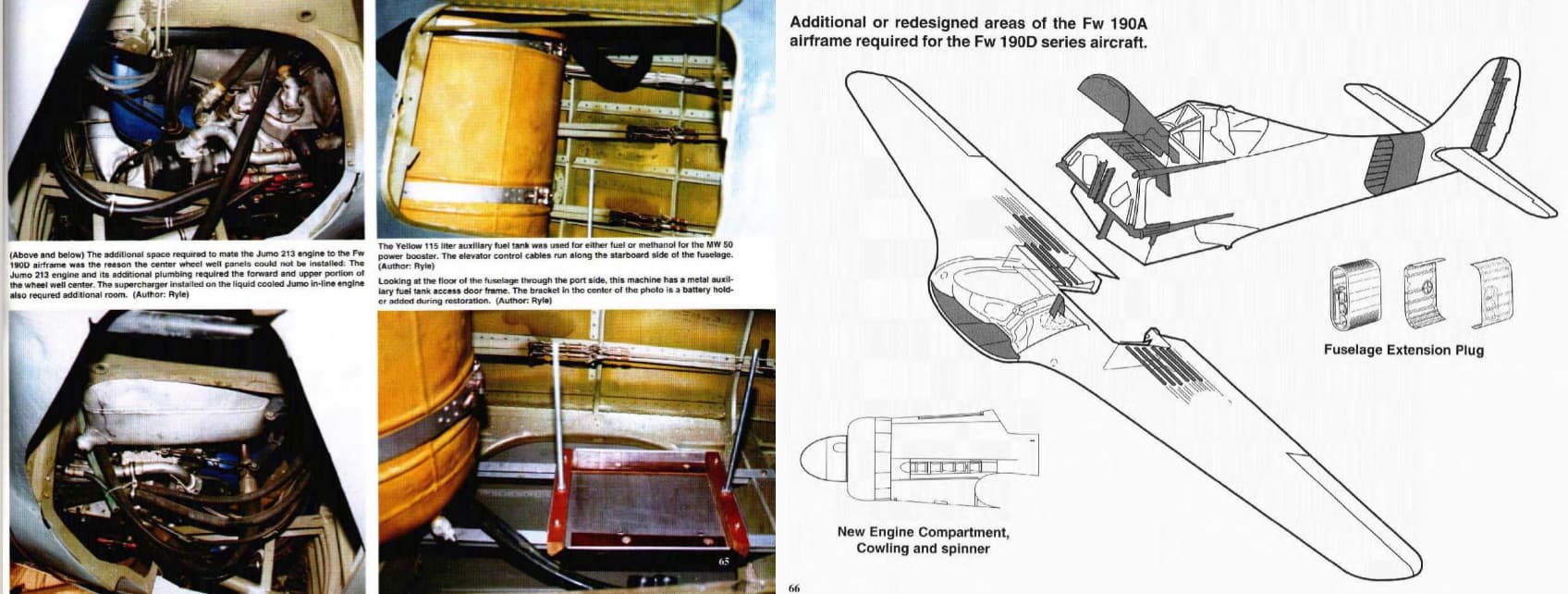

Jumo-213C

Variation of the Jumo-213A engine. The Jumo-213C was intended to equip fighters. It was possible to mount an automatic gun in the camber of the cylinders. The system for adjusting the angle of the propeller blades was changed. The engine had a flange to which the automatic gun was attached. Serial production began in September 1944.Jumo-213E

This modification was originally a Jumo-213A/C engine, which ran on gasoline with an octane rating of 95. The altitude of this engine is 9800 m. Two-stage three-speed supercharger with a built-in charge air cooler. The Jumo-213E1 version, powered by B4 gasoline (octane number 87), developed a takeoff power of 1750 hp. (1285 kW). Initially, it was planned to establish serial production of a more powerful version of the Jumo-213E0 with a takeoff power of 1870 hp. (1375 kW), for which C3 gasoline (octane number 95) was used. In the future, the developers expected an increase in takeoff power to 2000 hp. (1470 kW). However, by the middle of 1943, the production of C3 gasoline did not fully meet the needs of the Luftwaffe, and therefore it was decided to develop and establish serial production of the Jumo-213E1 with a slightly lower capacity. For variant E1 trB4 gasoline (octane number 87), produced in large quantities, was used. The MW-50 system, when used at altitudes below the design altitude, increased the power of the Jumo-213 E1 engine by 300 hp, while the consumption of the water-methanol mixture was 150 liters per hour. The duration of work in this mode was no more than 10 minutes, followed by turning off the system for at least 5 minutes. At altitudes above the calculated one, the use of the GM-1 system made it possible to achieve a short-term increase in power by 400 hp. The mixture supplied by the GM-1 system, depending on the mode, could be consumed at a rate of 60, 100 or 150 grams per second.

Jumo-213EV A version of the

Jumo-213E engine with a higher takeoff power of 1900 hp (1400 kW). The increase in power was achieved by using a more efficient supercharger designed to provide high performance at low altitudes. Bench tests of the engine were carried out. At the beginning of 1945, preparations were made for serial production of the Jumo-213E modification. The altitude of this version was 9000 m against 9800 m for the Jumo-213E1.

Jumo-213F

This modification was a Jumo-213E engine without intercooling of the injected air. Its functions were performed by a mixture injection system consisting of water and methanol (MW-50). This ground level engine developed up to 2120 hp (1560 kW). The altitude of the Jumo-213 F engine is 9500 m. This version was prepared for mass production in 1945. About ten engines of the pre-production batch were sent to the aircraft assembly plants of the Focke-Wulf company. They were used in Fw-190 D-11 fighters, which took part in battles. A small number of Fw-190 D-11 fighters delivered to the troops did not have any serious impact on the enemy, although the machines managed to prove themselves well.

Jumo-213J

This modification is a significantly redesigned version of the high-altitude engine. In this engine, the cylinder diameter was increased to 155 millimeters compared to 150 millimeters in the original version. The piston stroke has been preserved - 165 millimeters. The engine displacement increased to 37.36 liters. The maximum engine speed also increased, which was now 3700 rpm. Each new cylinder head received 4 valves instead of 3. In addition, the engine was equipped with a more efficient supercharger and a more advanced cooling system. By the end of the war, the engine was modified and extremely hastily began to be tested on the stand in the absence of the supercharger necessary for it, as well as a number of other units. It was not possible to conduct a full cycle of bench tests. Takeoff power was supposed to be 2250 hp (1655 kW). The MW-50 system increased power to 2600 hp (1910 kW). The extremely high parameters of the engine limited the engine life to only 40-50 hours, which made it possible to use the Jumo-213J engine mainly on fighters. The altitude of this modification was 11000 m.Jumo-213S

This engine was developed specifically for the Eastern Front, where the main air battles were fought at altitudes below average. The takeoff power of the engine was 2400 hp. Altitude - 4500 meters. Rathe bots on the Jumo-213S were close to completion by the end of the war, as it was quite simple to execute.

Jumo-213T

This modification was a high-altitude engine equipped with a turbocharger (ATL). At ground level, the power of the Jumo-213T engine was to be equal to that of the A, C or E variants - 1750 hp (1285 kW). The design power at an altitude of 11400 m was to be 1600 hp (1160 kW).

All of the above modifications of the Jumo-213 engine were developed in the last years and months of World War II in parallel. The shortage of the necessary materials and the ever-increasing bombing of the Allies significantly slowed down the progress of the work. At the end of the war, not all projects were tested, but a number of engines of the Jumo-213 series were manufactured and used. For example, a number of high-altitude modifications of the Jumo-213 engine (E and EB) were assembled in late 1944 - early 1945. About ten pre-production samples of the F modification were transferred to aircraft assembly plants.

The main goal of work on this type of engine was to obtain power plants small in size and weight. The transition from the production of the Jumo-211 engines to the Jumo-213, which was more advanced in all respects, was quite a difficult task. At first, the takeoff power of various engine options was close to the power of the first serial Jumo-213A, while the altitude increased, as well as the power developed at high altitudes. The last small-scale version of the Jumo-213EV had a slightly increased takeoff power. However, by 1943, the engine power of 2000 hp was not enough to confront the Western Allies, who had large resources at their disposal and had already begun production in increasing volumes of advanced piston aircraft engines, the power of which at a large range of altitudes was more than 2000-2200 hp.

Some previously abandoned projects and research were tried to be revived. Attempts were made to combine already loose or mass-produced engines, as well as to explore the field of turbojet engines more intensively.

Jumo-213 AG

A significant increase in power compared to previously developed modifications was supposed to be obtained on the Jumo-213J modification. This version of the Jumo-213 engine was a new type of aircraft engine with an altitude of 11000 m. The development of a new supercharger required considerable effort from the employees of Jumo and the use of all the experience accumulated up to that time in the development of piston aircraft engines. If the developers had the necessary time to develop this modification, the Jumo-213J could be expected to have the most advanced piston aircraft engine in a number of basic parameters. The difficult situation of German industry and the extremely short time available to the developers of the engine did not allow the production of this engine to be organized in a timely manner, as well as to thoroughly test the engines so necessary for the Luftwaffe. The first production versions of the Jumo-213 engines developed a maximum of 3250 rpm. This figure was very high, as was the associated average piston speed of 17.9 m/s, which was the maximum if we consider the piston aircraft engines actually produced at that time. Jumo-213J with its 3700 rpm and average piston speed of 20.35 m/s exceeded these already high parameters.

The average piston speed of the most advanced aircraft engines in the world for that time rarely exceeded 15-16 m/s. Already at these indicators, large dynamic and kinematic loads on the engine crankshaft began to make themselves felt. Dynamic loads on connecting rods and pistons, valve accelerations and huge loads on bearings and main journals were almost 2 times higher than in engines produced earlier. The resulting loads led to increased vibration and increased wear, which were higher than average for such aircraft engines. Without a doubt, this created many problems in design and production and led to a significant reduction in the resource of engines during operation. The reduction of the engine life of the Jumo-213J modification, intended for fighters, to 40-50 engine hours in a situation that developed in the second half of the war, when everything that was at the disposal of aircraft manufacturers was at stake, was justified. Such a reduction in engine life due to obtaining high power characteristics in civil aviation simply could not take place.

No data on the progress of bench tests of the Jumo-213J engine has been preserved. According to the company Jumo (rather scarce), only on March 14, 1945, 6 Jumo-213E engines were transferred to the appropriate department of the company for modification to Jumo-213J. The first converted model, designated Jumo-213JV1, was again used for bench tests. During the test, increased wear of valve seals and valve seats was revealed. Nothing more is known about the progress of further work on the Jumo-213J engine. In this regard, it is not possible to give a full assessment of the work on this engine.

The same can be said about the blower and the charge air cooling system developed specifically for the Jumo-213J, and there is no data on the performance of the heat exchanger and blower. Radial DischargeAircraft engines also had certain difficulties associated with mechanical limitations caused by the high angular velocity of up to 400 m/s. This value was the limit, and it could not be exceeded. The new two-stage supercharger of the Jumo-213J engine, which had a variable capacity depending on the stage and should have a higher performance than all those used earlier, still had to be completed (this would most likely also take a lot of time), and it was impossible to obtain it in the shortest possible time. This did not allow you to immediately obtain high performance of the entire power plant. In addition, it was necessary to increase the efficiency of the engine cooling system by 30%.

Previous experience showed that cooling-recuperation using the air-to-air principle was already ineffective in the Jumo-211. In this regard, the Jumo-213E engine used heat exchange not with the help of air, but thanks to the cooling system of the engine itself.

Due to its greater efficiency, the air-liquid-recovery cooling system could be smaller, had less pressure loss, and did not create additional resistance to the oncoming air flow. In a more advanced sample of the Jumo-213F high-altitude engine, the external cooling of the air supplied by the supercharger was replaced by a different principle of cooling the injected air. The cooling principle was based on internal cooling by an MW-50 water-methanol mixture injection system, in which the alcohol-water mixture fed into the engine cylinders contained 50% of these components each. When the mixture evaporated in the engine cylinders, the engine cooled without recuperation. In the Jumo-213J engine, it was presumably decided to use the same cooling principle.

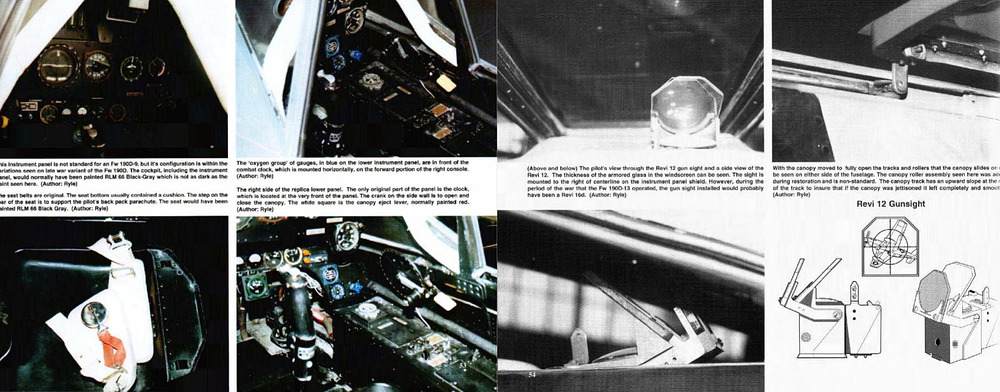

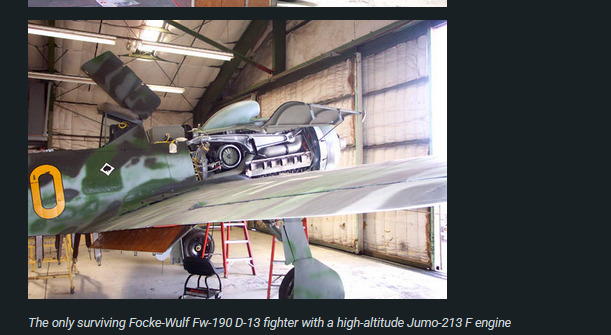

The only surviving Focke-Wulf Fw-190 D-13 fighter with a high-altitude Jumo-213 F engine

The development of new power plants of greater power was associated with the emergence of more and more problems. At the same time, a number of basic parameters could not be exceeded. This significantly increased the time to bring the power plants to an acceptable level of reliability. At the same time, the Jumo-213 engine showed that the principles of operation of piston aircraft engines came close to the limit, exceeding which became extremely dangerous. Reaching the limit values of some parameters had a negative impact on the time of bringing power plants, mastering their mass production, maintenance and repair.

The example of the Jumo-213 shows that the situation with the development of piston engines and the principle of their operation, regardless of the conditions associated with active hostilities, came to the limit beyond which further improvement of the characteristics of piston engines at the current level of development was no longer possible.

In 1943-1945, the Jumo-213 engine was often installed on a large number of German combat aircraft to improve their tactical and technical characteristics as a replacement for the Jumo-211 engine: Ta-152, Ta-154, Fw-190D, Ju-88G, Ju-188, Ju-388, Me-309, He-111H, He-219. The insufficient number of Jumo-213 engines produced affected the production volumes of most of these aircraft: they were not particularly large. In the summer of 1943, when the Jumo-213 engine had already been brought to the required level of reliability, all efforts were thrown into organizing their serial production in the largest possible quantity. The reason for this was that the fighting in the skies of Germany was becoming more and more acute. The use of Ta-152 and Fw-190D fighters equipped with Jumo-213 engines would make it possible to counter to some extent the increasing qualitative and quantitative superiority of the Allied air forces over the Luftwaffe.

Jumo-213 engines gradually began to replace the air-cooled BMW-801 engines installed on Fw-190 fighters, which had large dimensions and weight. The Jumo-213 engine at Jumo’s engine-building enterprises in terms of serial production pushed into the background the promising 24-cylinder multi-row Jumo-222 engines, which had even more power. The reasons for this were the long development of the Jumo-222 engines (mid-1942), as well as the lack of free production facilities and equipment to organize mass production of the Jumo-222 as soon as possible. For the manufacture of the Jumo-213 engines, it was possible to use some of the equipment and tooling used for the production of the Jumo-211 engine.

As noted earlier, Jumo specialists have made great efforts to increase the production of Jumo-213. In the city of Magdeburg, an automatic line for the production of cylinder heads for Jumo-213 engines was installed at an engine-building enterprise. It took no more than 2 minutes to process one cylinder. About 600 cylinder heads were machined during the day. The manufacture of other engine parts was also rationalized: valves, crankshaft and others. Jumo’s test rigs, despite the reduced duration of engine tests, continued to operate around the clock. According to Jumo documents, only 9163 Jumo-213 engines of various modifications were manufactured.

InsignificantJumo-213 production volumes were due not only to the above reasons, but also to the need to pay attention to the development and organization of serial production of the Jumo-004 jet engine. Work on this engine, so necessary for the Luftwaffe, was carried out in Dessau.

The E modification of the Jumo-213 engine became the pinnacle of the development of German aircraft engine building. However, in addition to various versions of the Jumo-213, there were many plans of the Jumo company, which were associated with attempts to develop more powerful engines based on it. From the negotiations between representatives of RLM and Jumo on November 10 and 11, 1938, it follows that already at that time there were plans to produce an experimental batch of Jumo-212 engines. Jumo-212 was a pair of Jumo-213 engines united by a common reduction gearbox. This power plant was considered as one of the options for equipping the He-177 heavy bomber. Another new engine was the Jumo-214 engine, which later became the Jumo-213C. An automatic cannon could be mounted in the cambers of the cylinders of this engine. The Jumo-215 is a twin Jumo-214 which, like the Jumo-212 engine, had a common gearbox for 2 engines. The development of the Jumo-215 began after the Jumo-212 engine successfully passed bench tests. After the end of World War II, work on the Jumo-212 continued in France. At the same time, no more work was done on the Jumo-215.

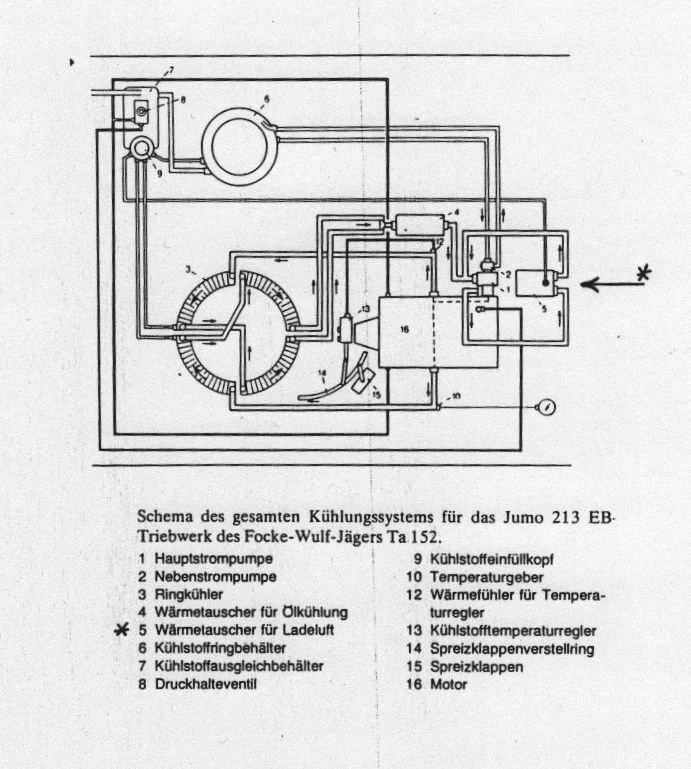

the radiator is the type used on the Ta152 and a few Ju388 but not the Fw190 D13 !!

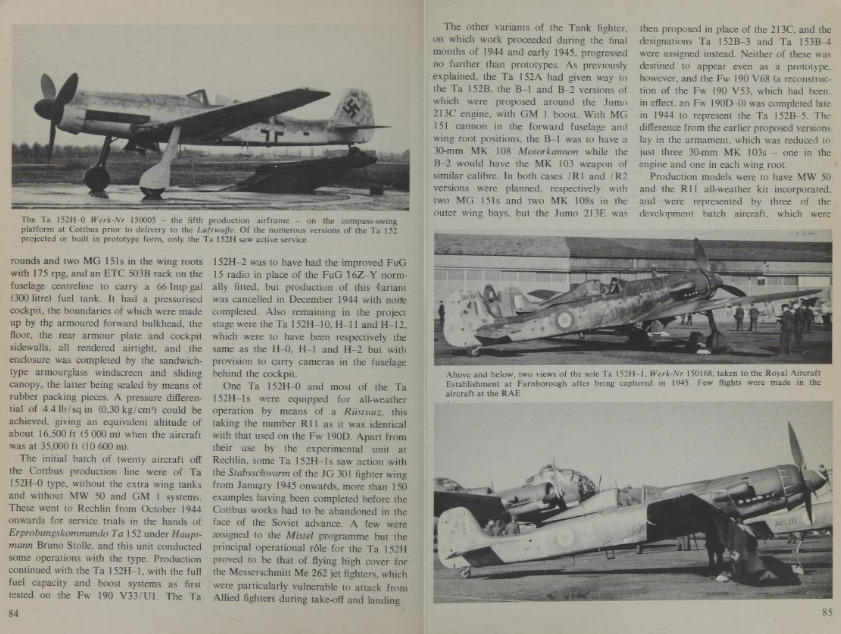

Ta 152

The Focke-Wulf Ta 152B was the original design for a version of the Ta 152 optimised for higher altitudes, but suffered from problems with its Jumo 213E engine, and never got beyond the prototype stage. However a modified ‘Destroyer’ version, the B-5, did reach the prototype stage late in the war.

At the start of 1943 Kurt Tank had produced a design for a replacement for the Fw 190 that would have looked similar but used a new airframe and more powerful inline engines. In April 1943 this project was rejected by the RLM (German Air Ministry) on the grounds that it would have caused too much disruption on the production lines.

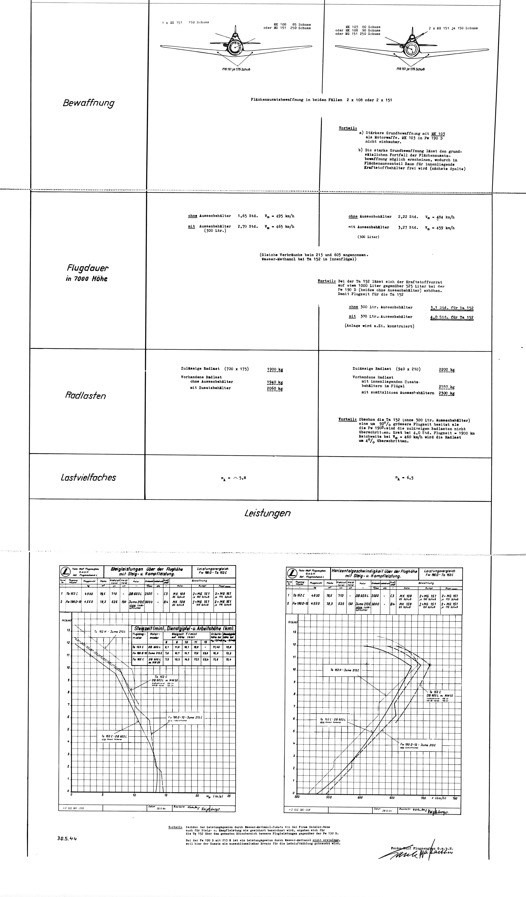

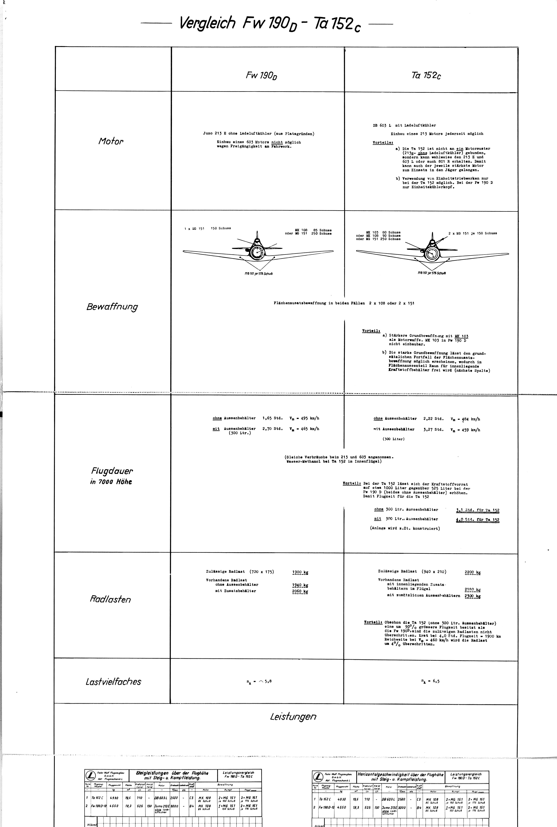

Tank responded with a less ambition design, using more components from the Fw 190. In May 1943 this was given the designation Ta 152A and two variants were produced. The Ta 152 was to use a Jumo 213A engine, optimised for low and medium altitude while the Ta 152B was to use the Jumo 213E, which had a three-speed two-stage intercooled supercharger that greatly boosted power at higher altitudes. Both versions were to be able to take the Daimler-Benz DB 603G engine if required.

Both aircraft were to use the same fuselage. This was based on that of the Fw 190A-8, but with an extra 77.2cm in front of the cockpit to fit the engine and some of the armament and a 50cm extension to the rear fuselage. The wings were moved 42cm forward to improve the central of gravity. The wheels were larger (740mm) and the wingspan extended by 50cm by adding another 25cm inside the wheels on each side. Both versions were to carry an engine mounted 30mm MK 108 cannon and four 20mm MG 151 cannon in the wings. They were also to carry a ETC 503 bomb rack below the fuselage.

Work on the Ta 152A made rapid progress, with the first prototype (Fw 190 V29) making its maiden flight on 7 July 1943. However the Jumo 213E engine proved to be more troublesome, and the Ta 152B was repeatedly delayed. New versions of the aircraft soon appeared to compete with it. In December 1943 Tank submitted plans for a very high altitude version, the Ta 152H, and six prototypes were ordered. In January 1944 the Fw 190D-9, an interim design using the Jumo 213A, was approved. At about the same time the Ta 152C, powered by the Daimler-Benz DB 603L was approved.

Late in 1944 the Ta 152B was temporarily revived, this time as a heavy fighter to replace the Me 410. The Ta 152B-5 was to use the Jumo engine, and be armed with three 30mm MK 103 cannon, one in the engine and one in each wing root. Production was to begin at Erla in May 1945 and at Gotha in July 1945.

Ta 152B -1

According to Focke-Wulf documents the B-1 was to have been armed with four 20mm MG 151/20 cannon, two in the wings and two in the fuselage, and a 30mm MK 108 cannon in the engine. It was to be powered by the Jumo 213E engine. It had three field conversion kits, each of which added guns to the outer wing position. R1 was for two MG 151/20s within the wings. R2 was for two 30mm MK 108 cannon within the wings. R3 was for two 30mm MK 103 cannon carried in gun pods below the wings.

Ta 152B -2

The B-2 was probably to have been similar to the B-1, but with the 30mm MK 103 cannon.

Ta 152B -3

The B-3 was either an armoured ground attack version, or the B-1 with a different model of the 213E engine.

Ta 152B -4

The B-4 was either a heavy fighter project or the B-2 with a different model of the 213E engine

Ta 152B-5

The B-5 was the revived heavy fighter version of the aircraft. It would have been similar to the Ta 152C-3, but powered by a Jumo 213E-2 engine with MW 50 powerboost. It would have been armed with three 30mm MK 103 cannon, one in the engine and one in each wing root.

Production was to have begun at Erla in May 1945 and Gotha in July 1945.

One prototype of the B-5 was built, W.Nr.170003. Some confusion has been caused by the decision to alter this aircraft’s V number, from V53 when it was being used to test the Fw 190D-9 to V68 when it was used to test the MK 103 cannon ready for use in the Ta 152B-5. The conversion was completed by 13 December 1944, and the aircraft went to Tarnewitz for weapons trials at the end of the year.

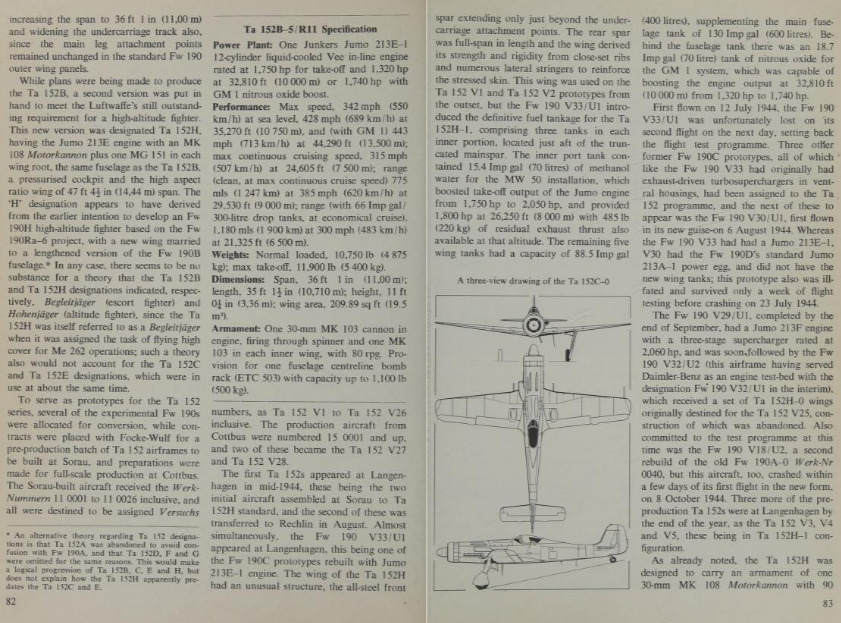

Ta 152B-5/R11

The standard version of the B-5 was to be the B-5/R11, with all-weather equipment. Early in 1945 the Ta 152C-3, armed with three 30mm Mk 103 cannon, was cancelled. Three of its prototypes, V19 (W.Nr.11019), V20 (W.Nr.110020) and V21 (W.Nr.110021), were allocated to the B-5/R11 programme instead. V19 and V20 were meant to be ready by March 1945 and V21 by April, but none appear to have been completed.

Stats

Ta 152 B-1 (Focke-Wulf official stats from January 1945)

Engine: Jumo 213 EB

Power: 2,00hp at take off, 1,580hp combat rating, 1,320hp max continuous power at sea level

Crew: 1

Span: 36ft 6.25in

Length: 35ft 6in

Height: 11ft 2 3/8in

Empty weight: 8,840lb

Maximum take-off weight: 11,728lb

Max speed: 395mph at sea level, 442mph at 14,436ft, 398mph at 32,809ft

Climb Rate: 9.8min to 26,247ft

Service ceiling: 36,743ft

Endurance: 705 miles cruising range

Armament: One 30mm MK 108 in engine, four 20mm MG 141/20

Source:

Rickard, J (23 April 2019), *Focke-Wulf Ta 152B

Books/Sources

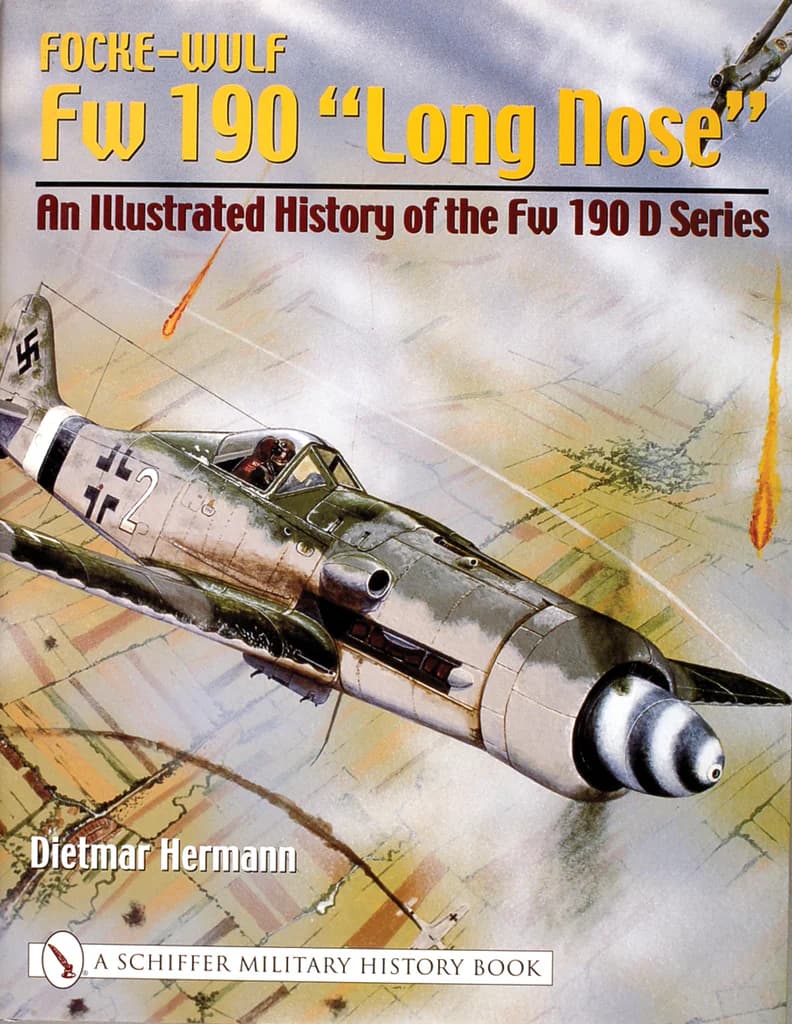

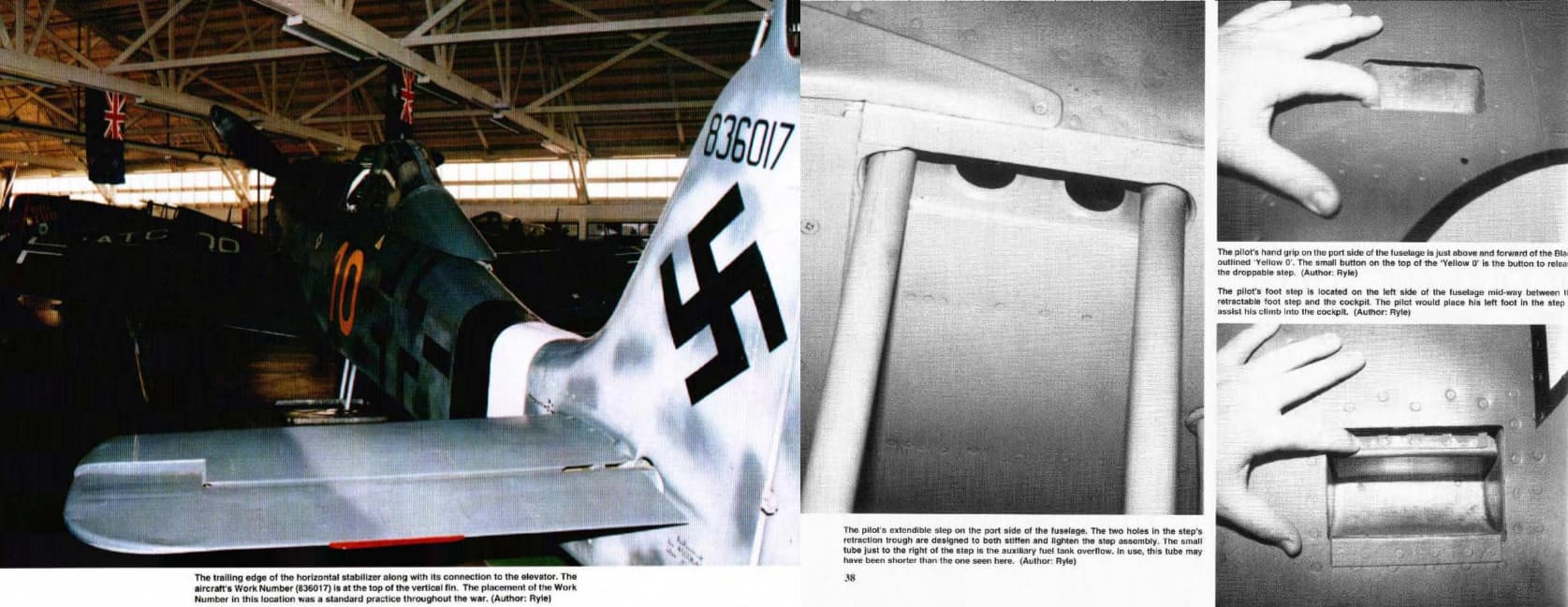

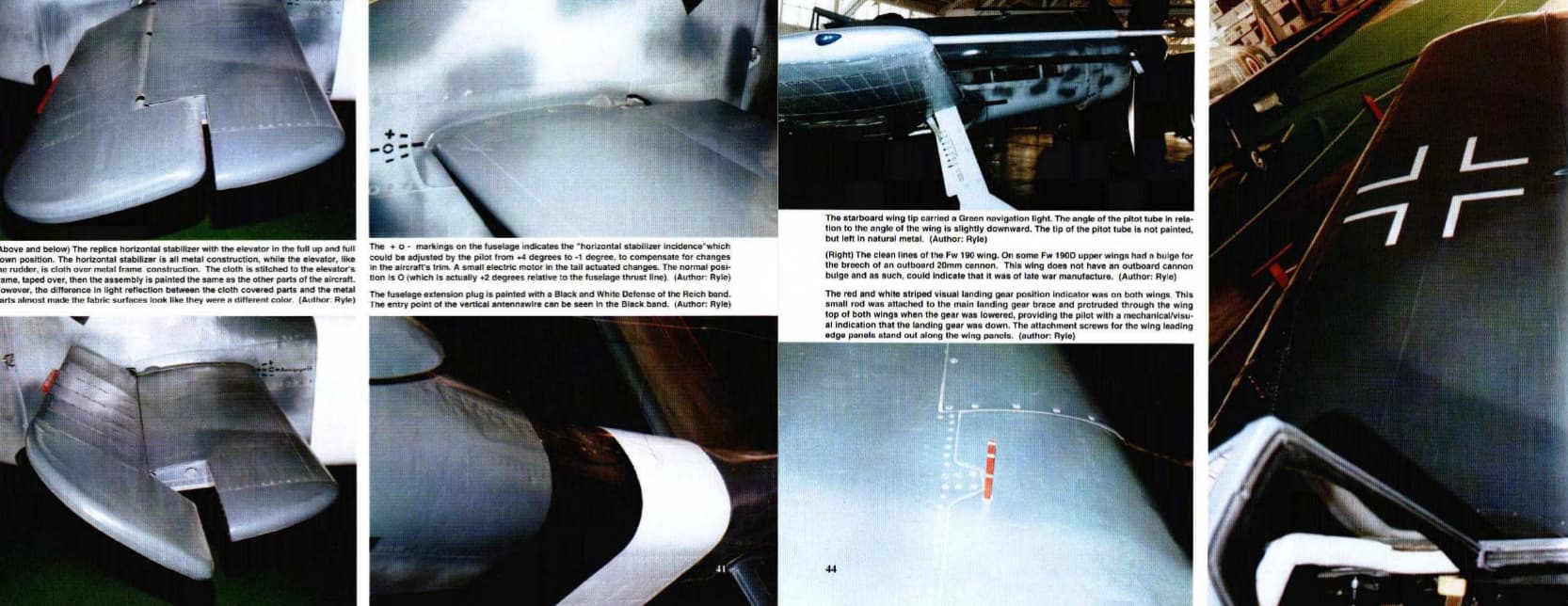

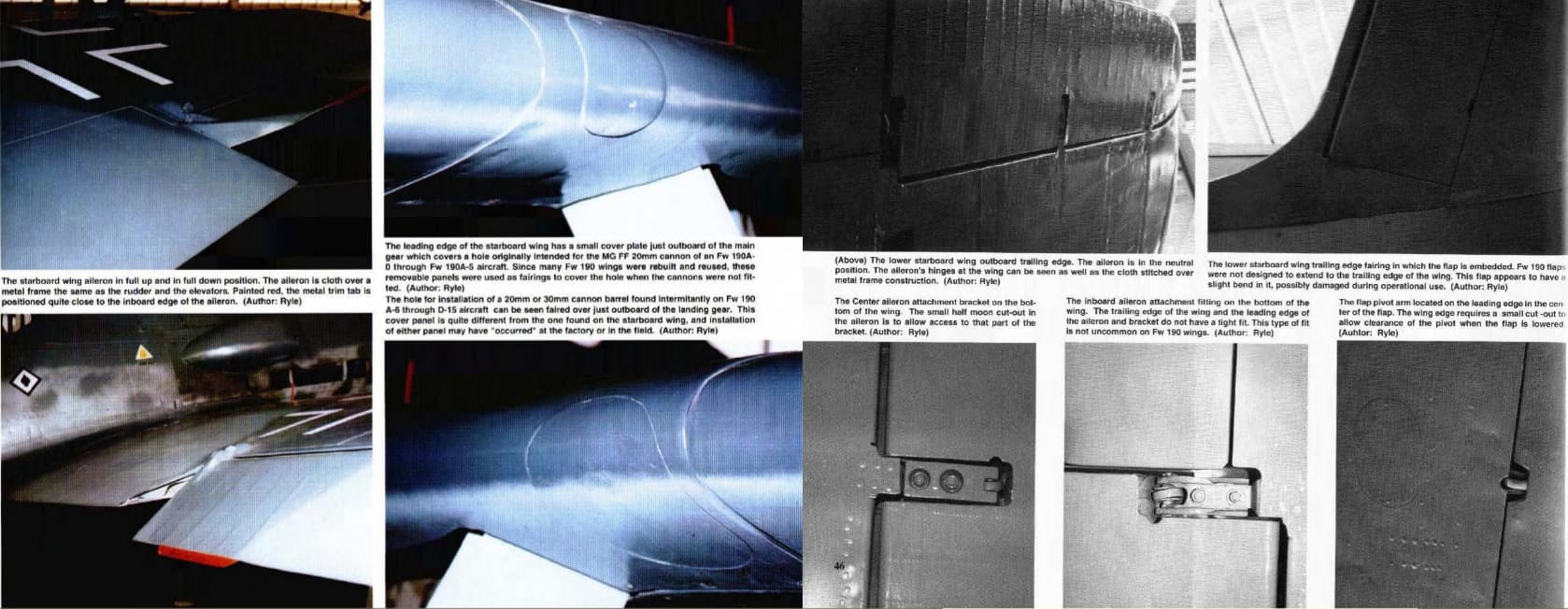

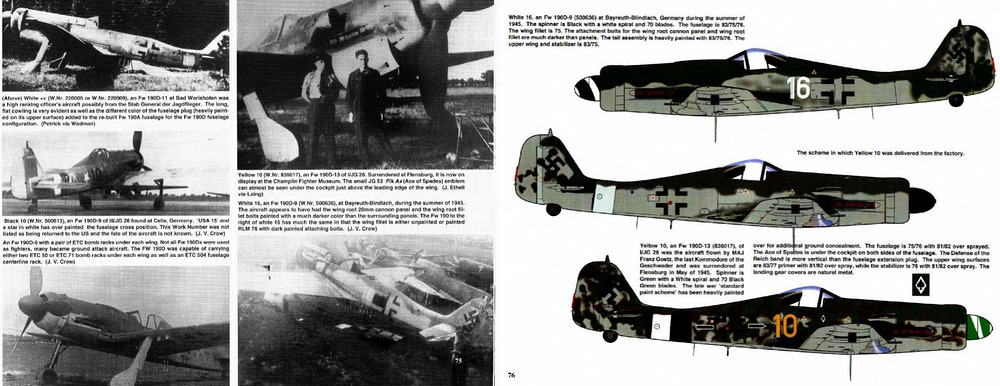

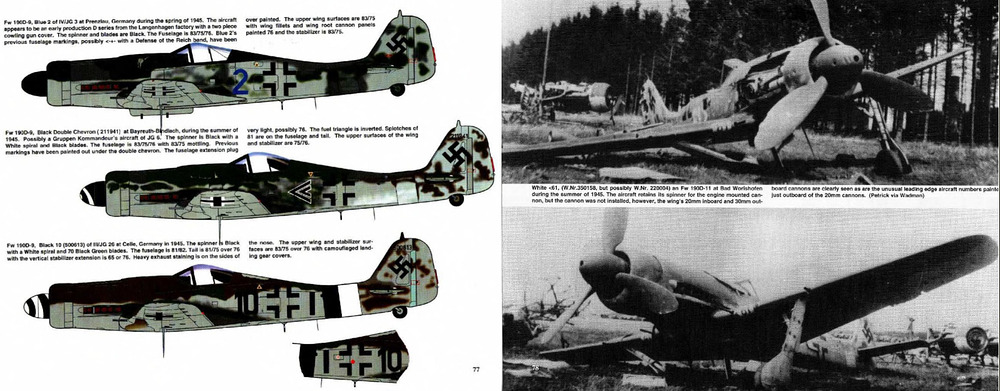

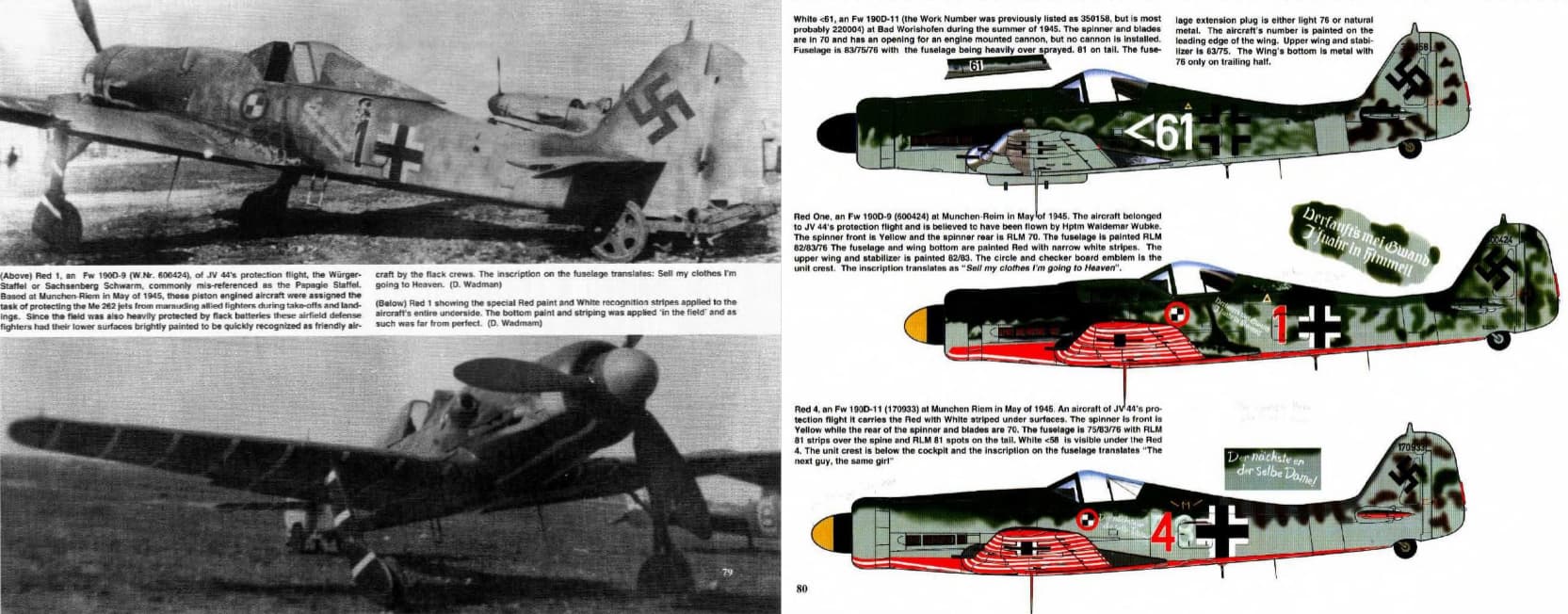

Jerry Crandall – Yellow 10: Story of the Ultra‑Rare Fw 190 D‑13

Jerry Crandall – Focke Wulf Fw 190 Dora D‑9/D‑11/D‑13

Focke-Wulf Fw 190 “Long Nose” : An Illustrated History of the Fw 190 D Series

By Dietmar Hermann

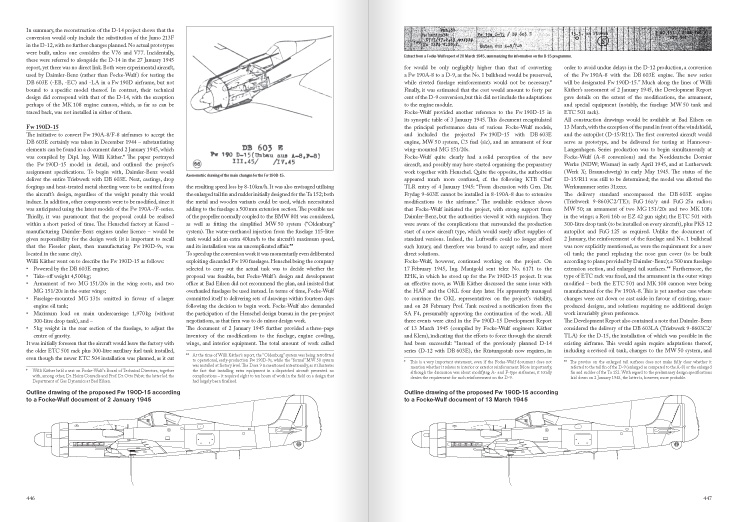

The first Fw 190 equipped with a Daimler Benz liquid-cooled engine took to the air in early 1942, followed six months later by another powered by a Jumo 213.

Production of the Fw 190 C, Fw 190 D and Ta 153 was delayed by the German air ministry. Not until 1944, by which time Germany had lost control of the air, did the Fw 190 D-9, an interim fighter powered by the Jumo 213 A, enter production.

The Fw 190 D-9 proved an immediate success, largely due to an excellent prototype test program under Dipl.Ing. Hans Sander. The type quickly entered service with the Luftwaffe and more than 1,700 examples were completed by the end of the war.

The Fw 190 D-9 gave rise to a number of improved variants with the more powerful Jumo 213 F engine and a heavier armament, however only a handful of the D-11 and D-13 versions were completed.

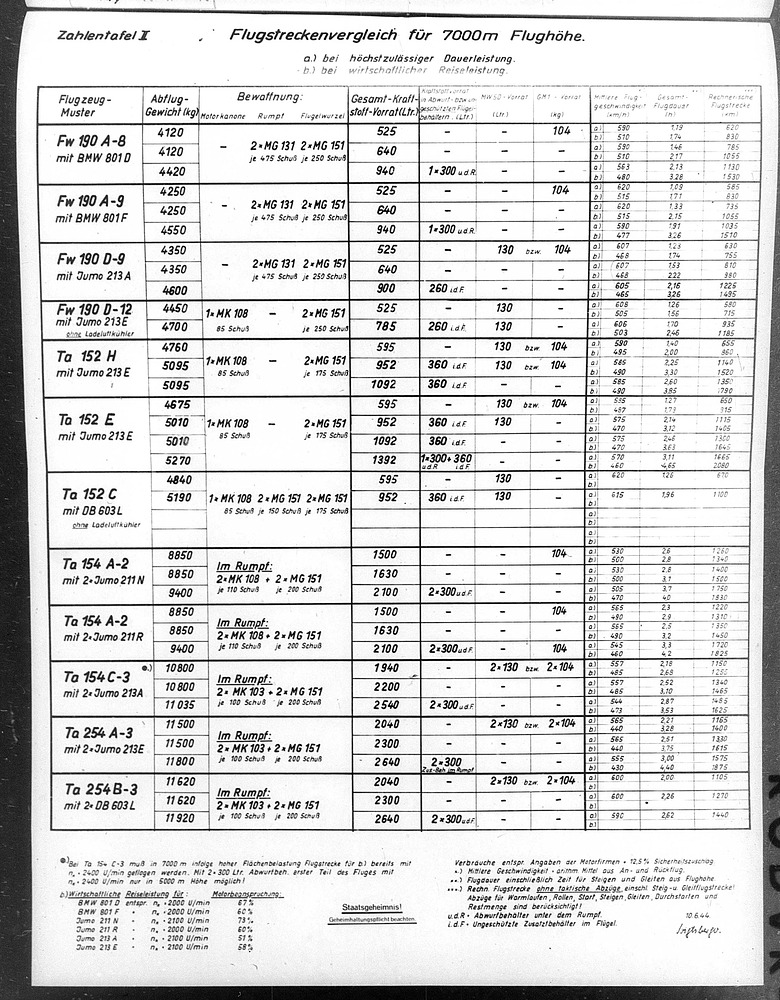

With a maximum speed of 750 km/h, the Fw 190 D-12 powered by the new Jumo 213 EB would have represented the apex of Fw 190 development.

The proposed Fw 190 D-14 and D-15, both powered by improved versions of the dive-bombers 603, came too late to see service with the Luftwaffe.

Fw 190 D13 30mm guns?

from online source

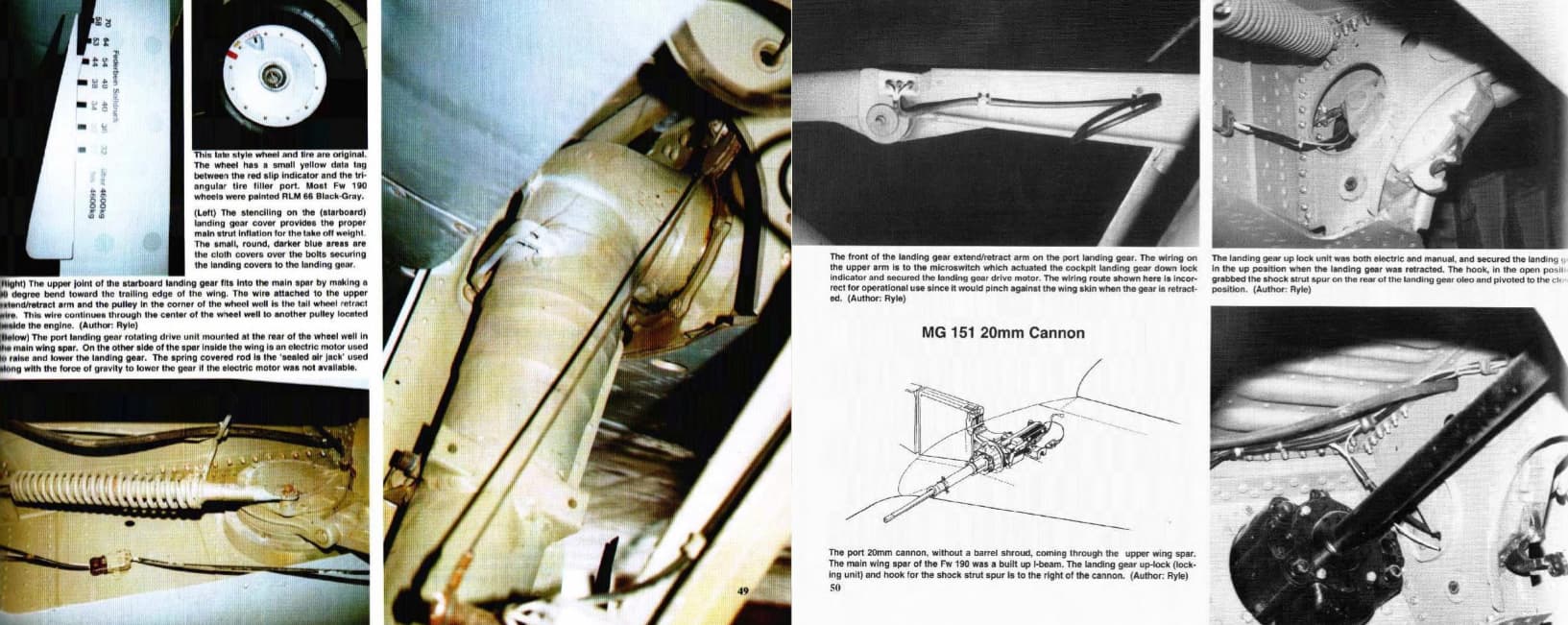

The D-13 I helped restore (Yellow 10) had a 30mm Cannon through the prop hub and 20mm in the wing roots. Photo in 1st image is the 20mm cans. In 2nd image, bottom right pic is the 30mm can with the twisting feed attached

another book talks about fw 190 and some about ta 152

Fw 190 D12/R21 fastest Fw 190 D12

to be clear the Fw 190 D14 is fastest but the Fw 190 D12/21 faster than fw 190 D13 at higher alt claimed!

The arrival of the Spitfire IX in Fighter Command and its threat to combat domination by the Fw 190A led to the development of the Fw 190B series with GM-1 power-boosted BMW 801D-2 engine and pressure cabin, but trouble with the latter led to the abandonment of this version after only a few prototypes had been produced. The Fw 190C series, of which five prototypes were completed with DB603 inline engines, annular radiators, Hirth 9-2281 superchargers and four-bladed propellers, was also abandoned early in 1944.

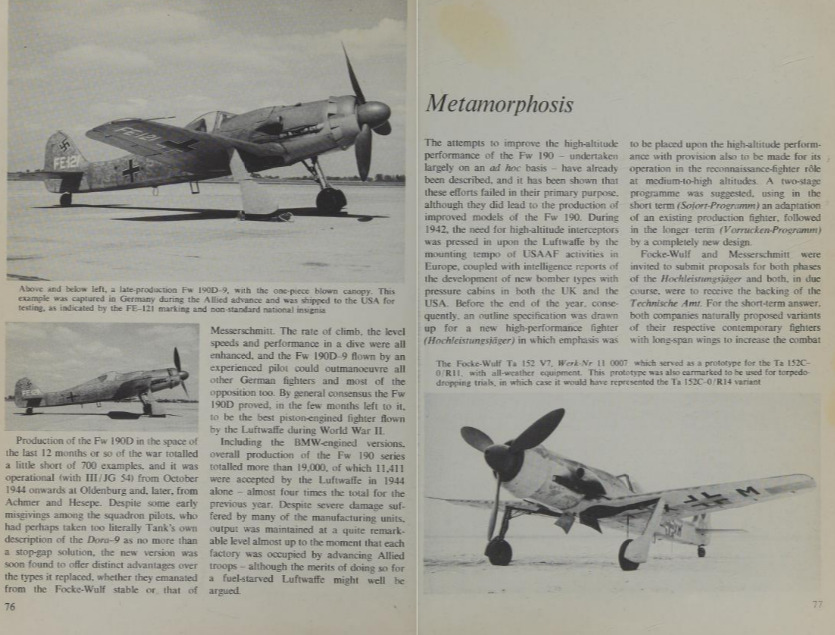

The Fw 190D, with 1,770hp Junkers Jumo 213A-1 engine and annular radiator in a much-lengthened nose (necessitating increased fin and rudder area), proved very successful after it had first flown at Langenhagen in May 1944. The first production Fw 190D-9s (so termed because they followed the Fw 190A-8s at the factories, and widely known as ‘Dora-Nines’ in the Luftwaffe) joined IIL/JG 54 in September 1944 to defend the jet base of Kommando Nowotny. Among the sub-variants of the Fw 190D series was the Fw 190D-10 with a single 30-mm MK 108 cannon located between the engine cylinder banks and firing through the propeller hub. The Fw 190D-12/R21, a ground-attack version of the hub-gunned Fw190D-10 and power-boosted with MW50 water-methanol injection, was almost certainly the fastest of all Fw 190s with a top speed of 730 km/h at 11000 m. Dora equipped most of the Luftwaffe’s fighter units during the last fateful months of the Third Reich, but in combat with the Allies – particularly their P-51s and Spitfire XIVs – they were frequently overwhelmed. The Luftwaffe’s problems centred on a shortage of fuel, which allowed only small formations of fighters, and of battle-hardened veteran pilots. For instance, when JG 6 (commanded by Major Gerhard Barkhom, the German pilot who had a combat record of 301 air victories) in April 1945 took delivery of 150 brand-new Dora-Nines, it could only fly patrols by four aircraft at a time against massed wings of Allied fighters.

Source:

David Donald: Fighters of World War II

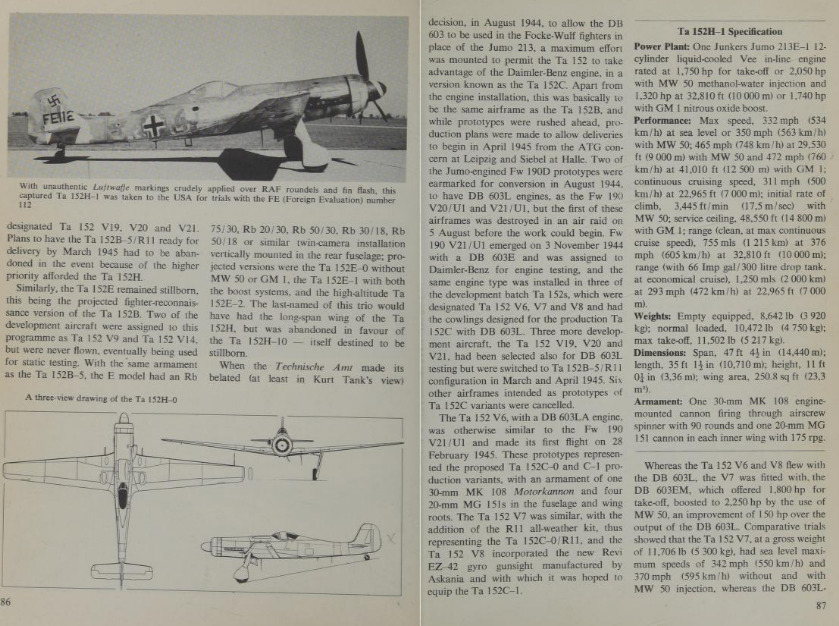

Fw 190 D14 / D15

Fw 190 D-15 really hard to find info about could be fake and not built no idea !

Fw-190D-13: Based on D-12 but replaced the 30mm motorkanone with a 20mm MG151/20. Also had all-weather flying equipment including the PKS12 and K-23 systems for steering and autopilot, FuG 125 radio, heated windscreen and hydraulic boost system for ailerons. At least 17 built, 2 of which are known to have seen service. One survives today, Yellow 10 of the Geschwaderkommodore of JG26, Franz Gotz (Wk. Nr 836017). Götz had 63 victories and flew this machine from March to May 1945 when he surrenderd it to the Allies at Flensburg.

Fw-190D-14: D-9 converted to use DB603 engines. Two prototypes built (V76 and 77). Based on work done on D-12. Flew in November 1944, cancelled in January 1945 in favour of D-15.

Fw-190D-15: a single prototype built (from a conversion). DB603 engine and enlarged tail section.

fw-190D-15: a single prototype built (from a conversion)

All I could find is this probably was Dora D-9 Wnr. 601286 (Fieseler Werk) found at Nellingen airbase.

more stuff also FW 190D13 had hydraulically boosted ailerons

Essentially the Ta 152C had a new bigger wing achieved by extending the roots with a new structure, this reduced wing loading and handled the extra weight. This was Kurt Tanks ‘escort fighter’. The Ta 152H added more wing span still, something that reduces roll rate and speed but increases ceiling and reduces turn radious. Both of the new wings had room for much more armament and prodigious fuel volume in 6 bag tanks one of which could carry MW50. The FW 190 generally did not carry fuel in the wings. The fueselage of the Ta 152 was significantly rearranged and also seems to have had provision for more fuel volume, it certainly was the first aircraft designed from the begining for GM-1 (Nitrous Oxide)

The Ta 152C used the DB603LA while the Ta 152H used the Jumo 213E1, both engines had about the same performance, the DB603LA was lighter and did not come with GM-1 as standard. Both could use MW50.

I believe both new wings used twin steal spars with mich of the rest wooden. The stall and aeroelastic characteristics would have been completely different to the FW 190 due to the way the wing twist under load and the greater geometric twist (washout). The stiffness of the FW 190 helped give the aircraft its fast roll rate but also made its stall a littpe harsher as wings didn’t twist under load to soften the stall.

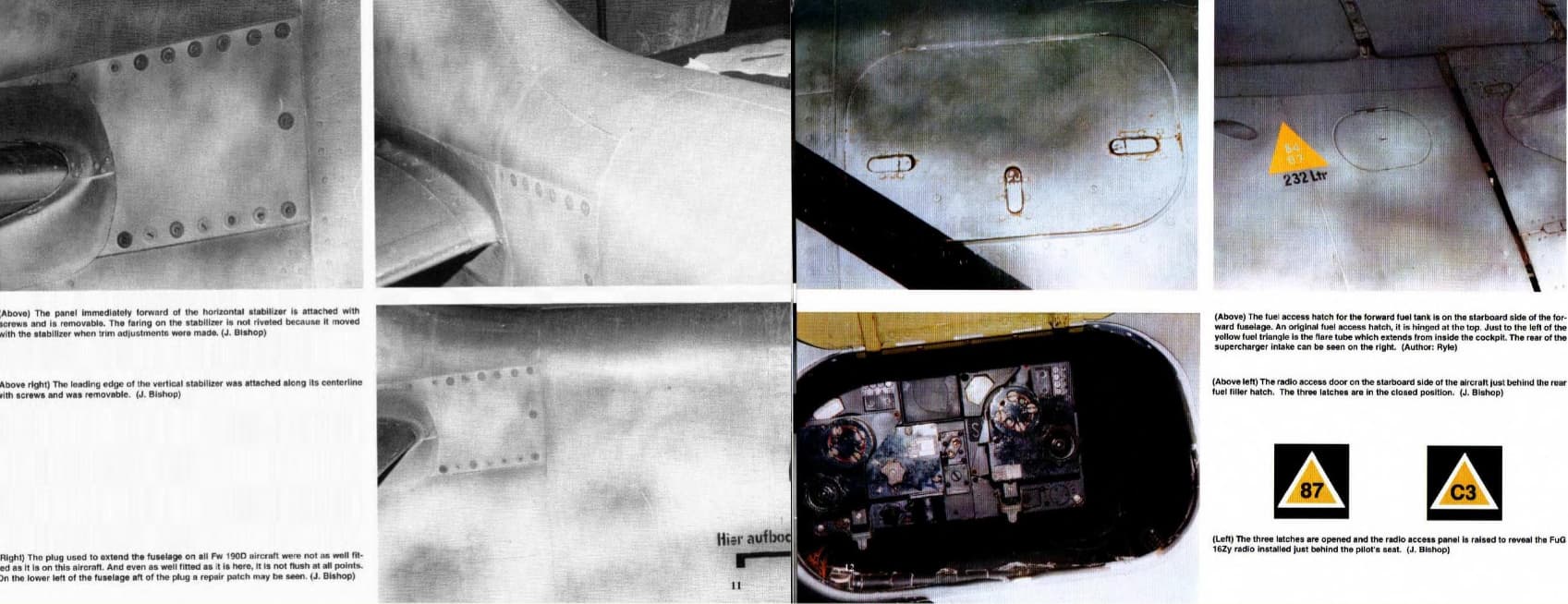

The FW 190D series was a straighforward adaption of the FW 190A8 with the BMW 801 radial replaced by the Jumo 213A, there was a slight lengthening of the tail with a ‘plug’ inserted in the tail to provide the extra tail momment for handling the longer nose. In other words much easier to manufacture.

The Jumo 213A used 87 octane B4 fuel and had a single stage supercharger and was left over from descheduled Ju 188 bomber production and had to be used up but in an ideal world the Jumo 213C would have been used for the FW 190D9. The Jumo 213C had the mounting for a propellor and guns that allowed a motor canon and also used C3 fuel for 2000hp. It was a fighter engine from the start.

The Jumo 213A receive several field upgrades: a rich mixture injection system that boosted power from 1770 to 1900hp on B4 and then the oldenberg MW50 system that used supercharger pressure to pressurise the MW50 tank and blow the mixture into the supercharger. Junkers shortly after that sent field technicians to install its even more powerfull high flow pumped MW50 system for even more power. Use of C3 fuel added even more power. (This all happened over 2-3 months or so FW 190D9 performance is all over the place). This was a very fast aircraft at low altitude.

The FW 190D12 and D13 varied as to whether they had Mk 103 of MG 150/20 motor guns. They were powered by the Jumo 213E, Jumo 213F or planned Jumo 213EB engines (oversized valves) which had two stage 3 speed superchargers and so much better high altitude performance. Speed about 455mph. There were no synchronised MG 131 guns as the motor hub 20mm guns was enough.

Some variants of the FW 190D13 (I think the R3) were to receive wing fuel tanks, presumably taking up the space no longer needed by the outer wing guns. The 3 x 20mm guns being enough.

(It was recently discovered that the Goetz Yellow 10 FW 190D13 had hydraulically boosted ailerons which was to be incorporated into the TA 152. )

Eric Brown mentions that the roll rate of the FW 190D was less, I suspect this is inertial coupling of the longer body; the hydrauic boost should have more than made up for that.

The D-13, which is much like the one Brown tested (his dora was a D-13 and not a D-9 but nobody knew what one was at the time, it was the one sent to the Smithsonian afterwards so it got examined later and the two-stage 213F motor and hand finished build quality was revealed, so Browns Dora evaluation no longer relates to D-9 in service trim but there is a superb one done by Wright-Patterson by two different test pilots and compares a regular service D-9 against the Mustang as a measure). Anyway the D-13 uses a shorter, lighter version of the basic 213E motor, it lacks the intercooler (oddly enough the 213A is actually a derivative of the 213E as well rather than the other way around, a simplified blower was put on for rushed production whilst development of the multiple stage one continued).

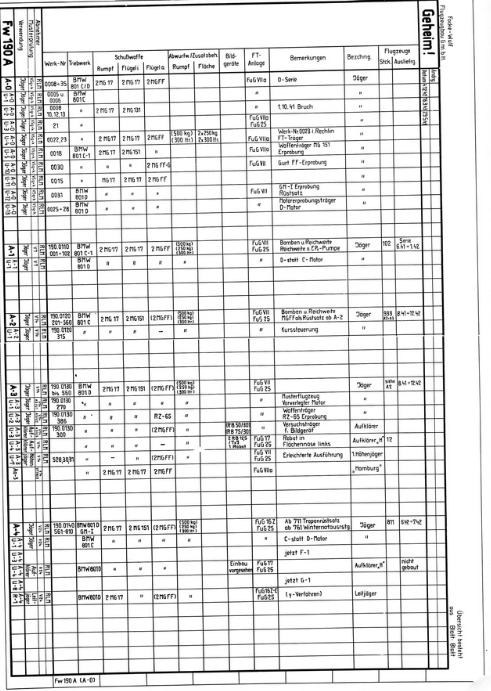

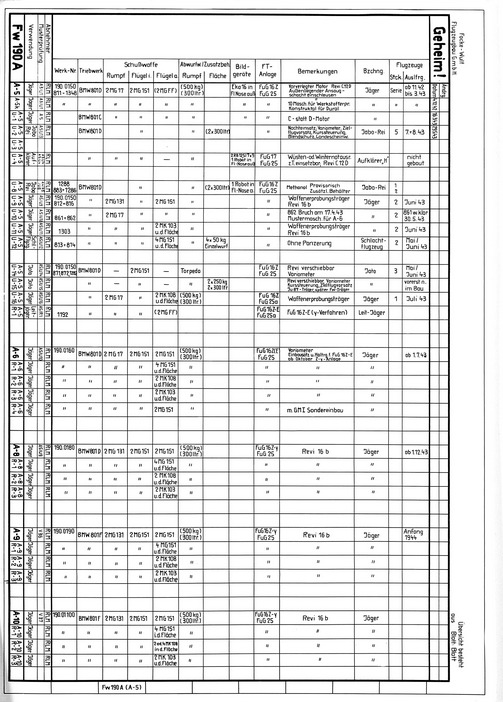

more info about FW 190 D14/15 1/16/2026

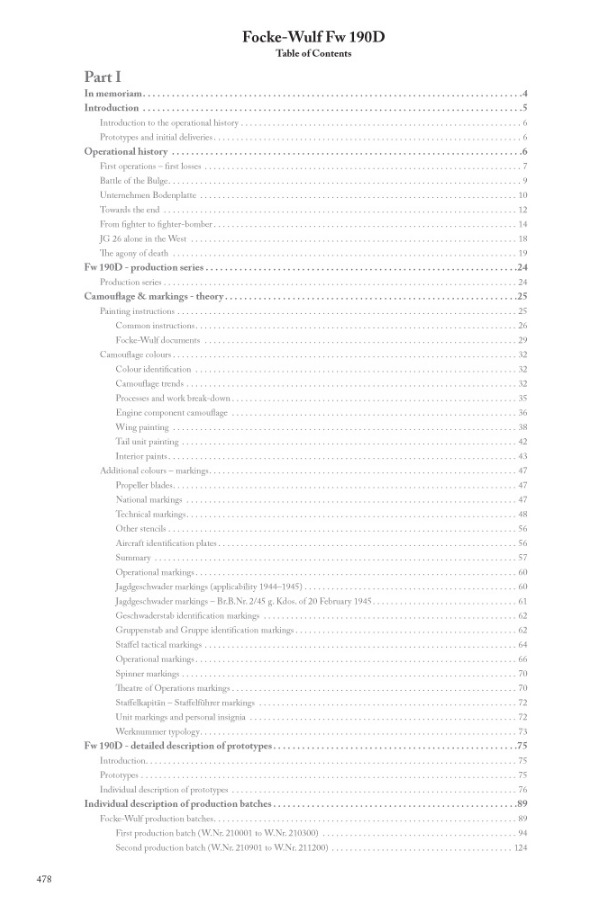

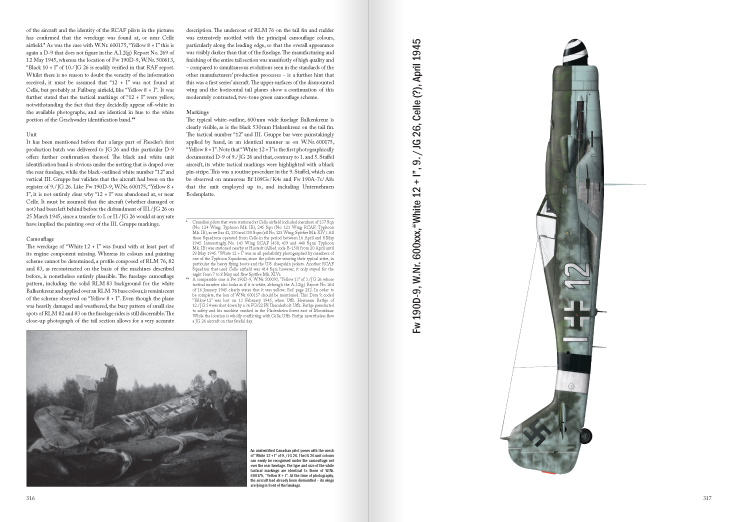

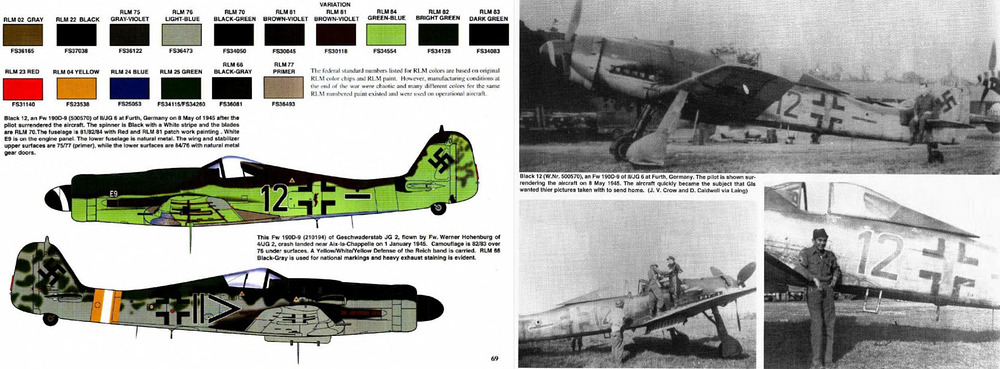

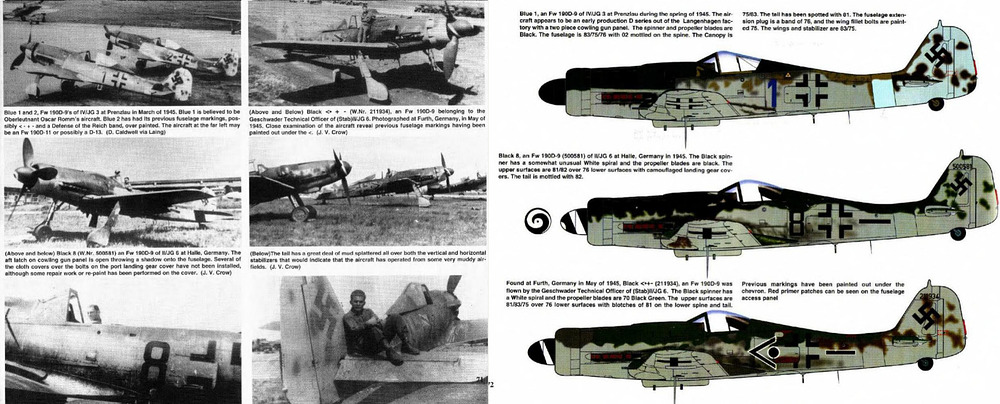

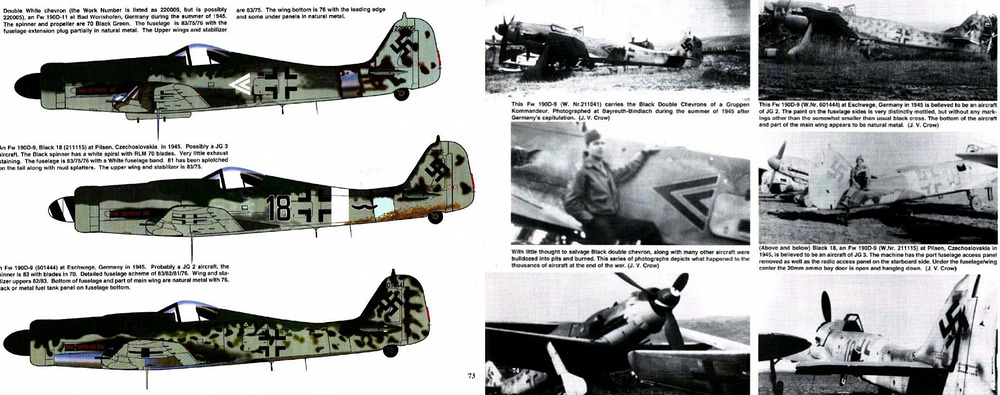

[Focke-Wulf Fw 190D camouflage & markings, Part II

Extract from the Chapter “Individual description of production batches” – Mimetall production

[Focke-Wulf Fw 190D camouflage & markings, Part II]

Extract from the Chapter “Individual description of production batches” – Fieseler production

Extract from the Chapter “Snapshots in Time”

Extract from the Chapter “Fw 190D-15 – the ultimate development”

Extract from the Appendices

Questions:

- Does the fw 190 D13 have 2250 hp with boost?

- Does the fw 190 d13 use the right engine type?

- Why in game fw 190 d13 have the E engine instead of the the F engine which fw 190 d13 & d12 used in really life ?

- Does anyone have data for fw 190 D13 or info about engines ?

- Fw 190 d13 should use jumo 213F-1 engines or am missing anything?

New question

-

Was the Fw 190 D12/R25 built with EB engine?

-

which is the fastest Fw 190 D built?

Extra:

I really hope snail rework Fw 190 D models at one point.

Extra Extra info about the Fw 190 D15:

at least one prototype (Werknummer 601286) was likely converted from an Fw 190 D-9 airframe this info could be right or could be wrong.

Fw 190 D14/D15 post here by program

Post about it here:

Fw 190 D-14/D-15 & Jumo 213EB to counter Allied superprops

Thanks for reading the post !

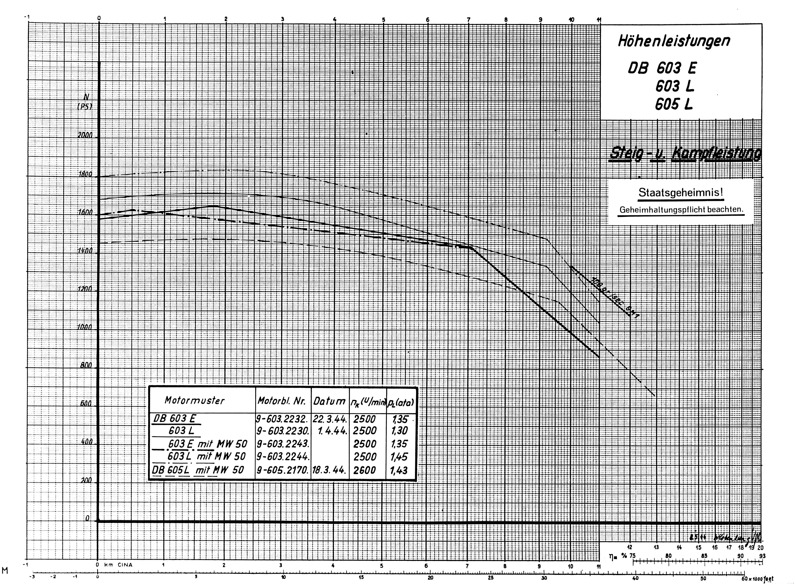

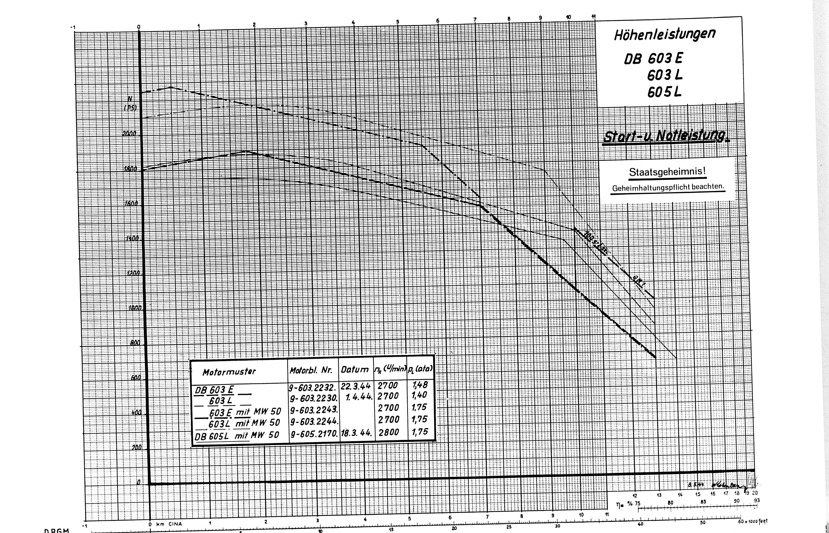

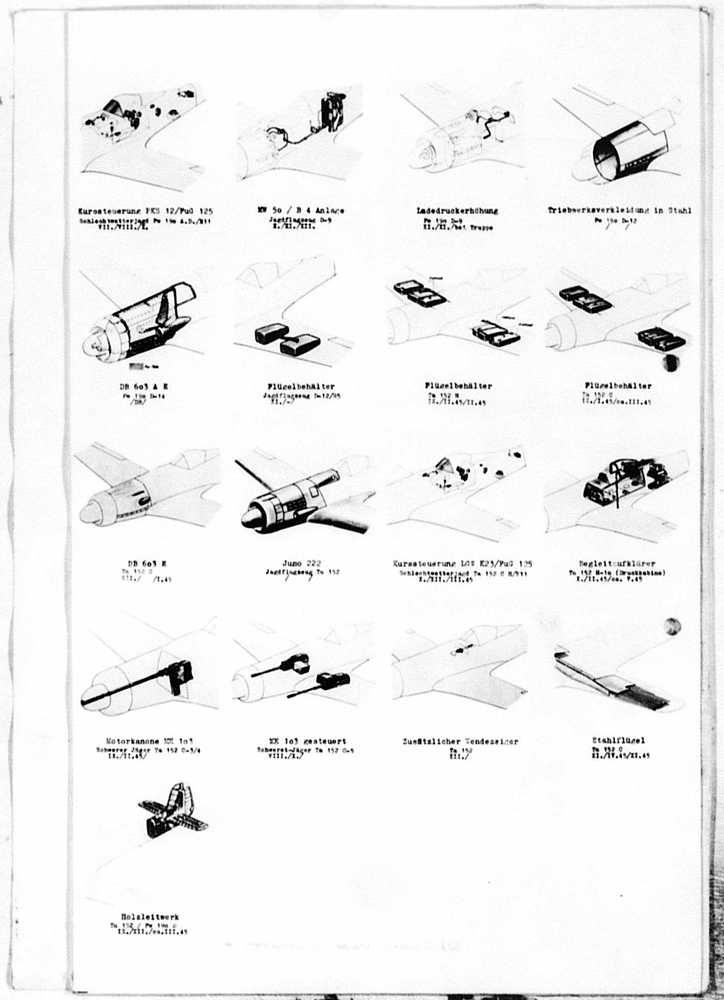

from same book i found these about the DB 603 E engine

from same book i found these about the DB 603 E engine

war thunder pc

war thunder pc