yeah idk on those

this is from a report in ~1970 about installing wing slats

so its definitely safe

yeah idk on those

this is from a report in ~1970 about installing wing slats

so its definitely safe

its an issue for all f15s

heres a source for the f15c with the -220 engines

https://web.archive.org/web/20111014195242/http://alternatewars.com/SAC/F-15C_Eagle_SAC_-_February_1992.pdf

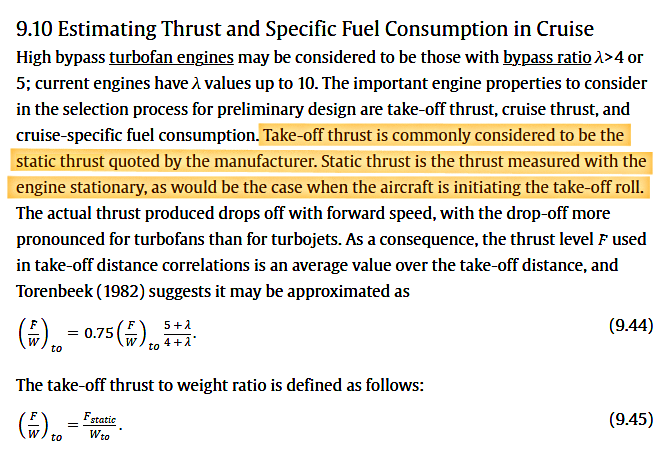

that clearly states static uninstaled thrust of 23,450 lbs per engine (46,900 lbs total)

whereas currently in game (at 100m altitude) it has ~17120 kgf of static thrust total

which converts to ~37,800 lbs

which is a loss of ~9100 lbs or ~19.5%

There is no such thing as channel loss in aerospace propulsion and integration. That is a made up terminology taken from telecommunications regarding the propagation of RF signals. There is no such thing as channel loss in airworthiness certification within the DoD and FAA when manufacturers test and publish thrust ratings within the OPERATORS/FLIGHT manual.

All thrust ratings that are found in ANY flight manual are provided when the engine is INSTALLED and is already corrected for all INSTALLATION LOSSES. The thrust provided in all flight manuals are stated for static thrust at sea standard day which means take off thrust.

I have tons of FAA & DoD airworthiness certification regulations that state ALL installation losses must be applied to the thrust ratings on any aircraft flying for the DoD and FAA.

The thrust you see in operations flight manual is installed thrust. It is highly illogical to continue to proclaim that a manufacturer would ever provide aircrews a flight manual with thrust ratings of their vendors engines as they sit on a test stand.

The thrust ratings are generated as a baseline thrust and is regulated and certified by the DoD. All of these American fighters are grossly underperforming.

ziggy is back? feel like i havent seen you in like 2 years lmao

Good to see you again K.

That’s for flight manuals. The ones on the engine brochures indicate bench thrust with no intake losses, you cant exactly compare those values to those once installed on air craft.

intake losses is definitely a thing no?

It is, installation loss covers duct lost and any airflow distortion applied when the engines are installed in the aircraft.

Manufacturers are required by the DoD to publish thrust ratings with all installation effects accounted for. They are also regulated to select the lowest thrust rating tested that all engines of the same type can reliably produce together.

This is to ensure a baseline thrust that pilots can rely on when performing critical ground operations like take off and landing.

correct, brochures are different from operations manuals

for example the MiG-29G

That is an operations manual that correctly labels the installed thrust

I have a good example of the certified thrust in flight manuals that is corrected for all installation loss and the brochure I will add for example.

(sent pm of one example sales brochure vs flight manual)

well

could that be reported?

Could you please post said regulations and their sources?

yes, proper education of the community & research into airworthiness certification and the strenuous requirements that all manufacturers must abide by are the first step.

the FAA, DoD as well as the ICAO (MiG-29 & other Soviet exports) operate to these same standards regarding thrust ratings found in flight manuals. Many aircraft do not operate anywhere close the real world.

Installation loss is always corrected in the operations manuals to static thrust at sea, standard day.

Take-off is the most critical element to manned flight. The thrust rating is the baseline rating that aircrews must rely on in this process. The thrust has been corrected by the manufacturer and is verified by the governing authority.

Standard day @ sea level represents the aircraft under normal temperature at take-off when the engines are not assisted by ram effect and mass airflow as when in flight, again providing the baseline thrust that the engines will always reliably provide the aircrew.

I do not want to repeat myself with information that isn’t helpful as I am not authority on the matter. I will share everything one the matter as soon as I get reorganized (been in Europe all year).

As soon as I get situated, please give me a day or two

Plenty of US aircraft manuals explicitly state the thrust values listed are for uninstalled engines on static test stands. And there are plenty more where the stated “static thrust” value matches the uninstalled test bench thrust listed by other sources (e.g. brochures).

A few examples I found after a quick search (all manuals are contain no distribution restrictions):

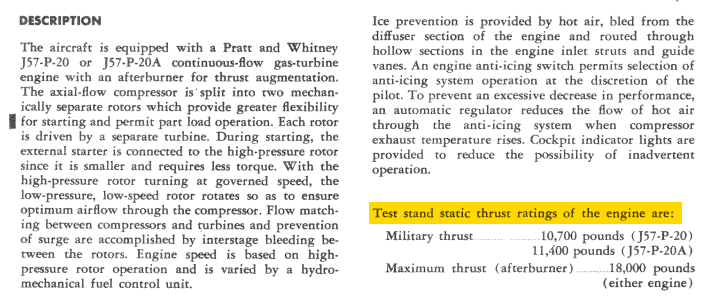

F-111D

F-111F

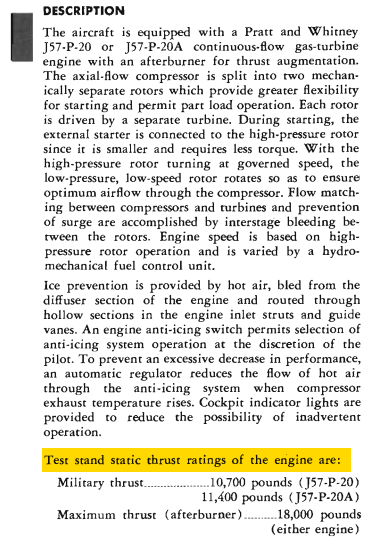

AV-8A

F-8A / F-8B

F-8D / F-8E

F-8H

I also am unsure if more recent manuals even have thrust ratings in them

eg.

1995 updated F-4E manual

vs

1979 updated F-4E manual

also manuals that I am unsure of distribution that I have checked do not seem to have thrust rating, or at least it is not in that location

still doesnt explain why all the F-15s in game static thrust is ~20% lower than the uninstalled static thrust, which absolutely does not make sense with the size and shape of their intakes

edit:

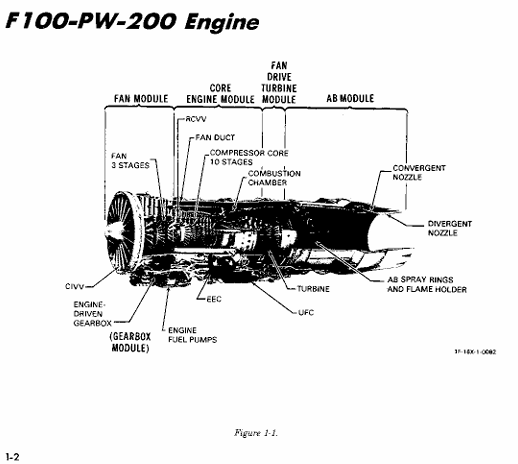

found a 1984 manual with thrust rating but it gives next to no information

right after this on the next page is the fuel system section

with this being figure 1-1

Ziggy and being fundamentally wrong about stuff…name a more iconic duo.

Unless explicitly stated otherwise yes, ALL THRUST RATINGS found in flight manuals are corrected for installation loss. Including the terminology, you refer to as “channel loss”.

Flame you continue to disinform, not by intention but by stubbornness. Tell me, what does this ultimately accomplish? That I need to be super duper specific moving forward? Yes.

My apologies for stating all as in every single rating found will be corrected. The correct statement I should have made was, “unless explicitly stating otherwise, all thrust ratings found in the operational/flight manual are corrected for installation loss & is FAA, DoD & ICAO certified.”

This mistake does not eliminate the DoD, FAA and ICAO’s authority on the matter. Does it???

Well, how about this, just let me supply everyone with papers on static thrust sea level testing, papers on why it is the best solution for determining a baseline thrust (take-off thrust): Static thrust at sea, standard day, & why until now Gaijin (including yourself) incorrectly believed that static thrust @ sea standard day actually meant uninstalled thrust. You, even going so far as to actively teach this on other platforms as well. I do understand why this is a hill worth dying on for you.

Please let me provide the research and let community evaluate & you still correct me when I slip up at the same time making sure the core of my argument is still on point, deal?

You know you missed me…I missed you. Can’t totally say the same for the other yet, however.

Btw…fundamentally wrong about stuff? You believe these aircraft are operating with real world thrust values & I am wrong about that? That is the fundamental point.

Since when did you decide to sell out & give up on the realism of these models?

Please do share these documents you keep mentioning once you get situated, more information being out in the open to inform discussion would not be the bad thing.

In the meantime as you have accused me of misinforming people I feel I should set out my own position, with accompanying evidence. Firstly I will acknowledge having used the term “channel loss” in the past; this is indeed not the technically correct term, however it was the term used by developers (probably a poor translation from Russian) so I stuck with it on the old forum. I have since switched to using the correct term “installation losses”.

As far as I can see we both agree that installation losses are real (i.e. an engine will produce more thrust when on a static test bench compared to when it is installed in the aircraft), and that a brochure produced by an engine manufacturer will typically list the sea level static test bench thrust (i.e. uninstalled thrust) unless otherwise stated. That means the only thing up for debate is whether the thrust value given in flight manuals is installed or uninstalled by default, correct? Please do let me know if you disagree with that summary.

In my experience it seems that flight manuals typically list the uninstalled thrust of the engine, unless explicitly stated otherwise. As I noted in my original post I’ve seen plenty of examples where the manual simply states “thrust” or “static thrust”, then lists a value matching the known uninstalled thrust of the engine. With the frequency I have seen this occur I do not believe you can possibly make a blanket statement that thrust in aircraft manuals is always installed unless stated otherwise.

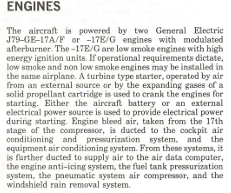

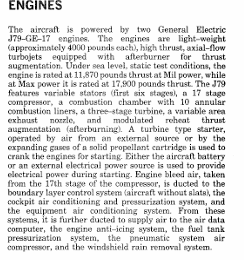

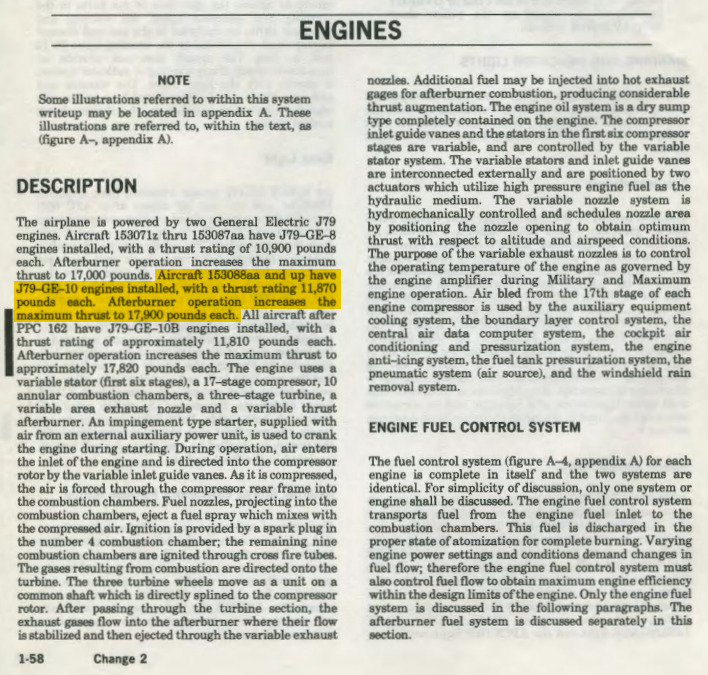

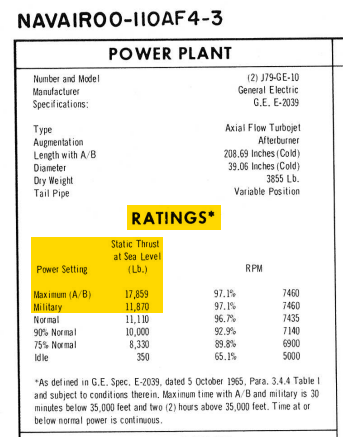

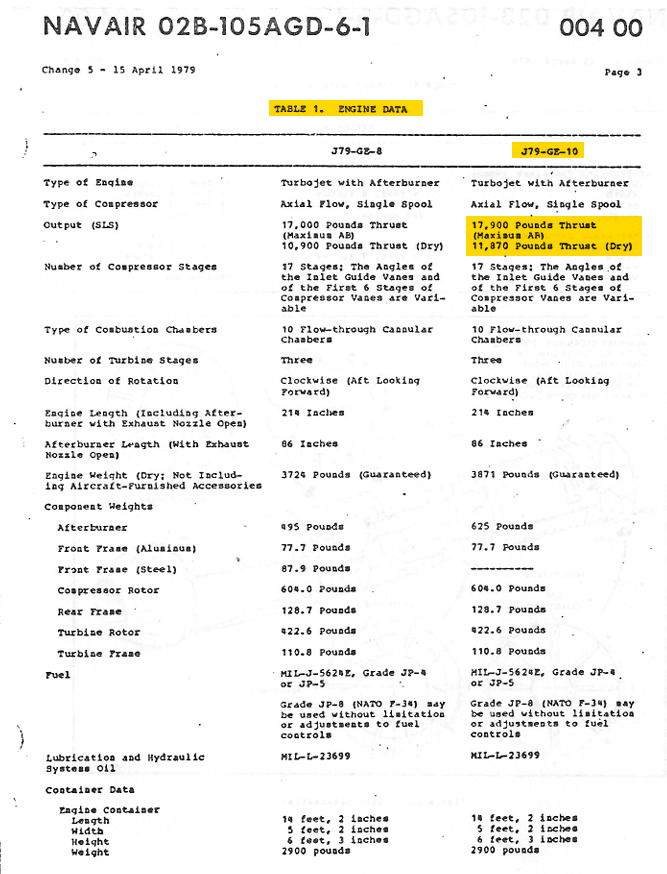

Lets take a look at one such example in detail. The F-4J Flight manual states the J79-GE-10 engine produces 11,870 lbf at military power and 17,900 lbf at maximum afterburner.

If we look at the J79-GE-10 engine data sheet we can see that the guaranteed thrust ratings are 11,870 lbf at military power and 17,859 lbf at maximum afterburner.

But maybe that engine datasheet is actually listing installed thrust? I guess that’s possible so let’s keep digging; if we look at the F-4J SAC it again states the engine ratings are 11,870 lbf at military power and 17,900 lbf at maximum afterburner, which perfectly match the values on the datasheet.

Notice how the SAC uses the term “ratings” rather than “power”. According to MIL-C-5011A (the military standard defining the creation of SAC documents) the term “power” in a SAC document indicates a value which includes all installation losses, while the term “ratings” explicitly indicates a value which excludes installation losses. So we can say with some confidence that as the SAC uses the term “ratings” the values listed in the SAC document (and by extension the datasheet) are the uninstalled thrust values.

3.2.8 Power - The term “power” shall be used to mean brake horse-power and/or thrust as applicable with due consideration for installation effects and limitations.

(Engine and JATO “Ratings”, as defined in paragraphs 3.1.1.1.2.1 and 3.4.3.1.4, shall be those which appear in the approved engine model specification without regard to installation effects or limitations.)

But what if the SAC author accidentally wrote “ratings” instead “power” and the values in the SAC and the datasheet are both meant to reflect installed values. Well I guess that’s possible, if unlikely in my opinion, so we could investigate further still. Let’s consult the J79-GE-10 Maintenance Manual, specifically the Engine Functional And Performance Tests section to find out once and for all how much thrust the engine produces outside the aircraft, on a static test bench.

The procedure for testing the maximum thrust of the J79-GE-10 engine can be summarised as follows:

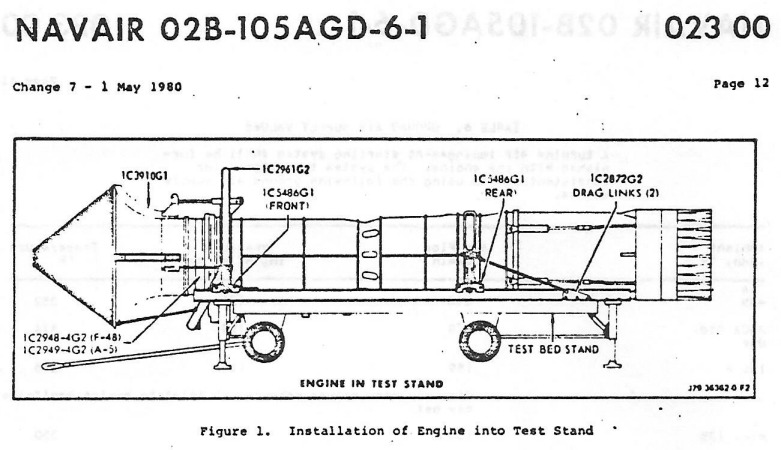

So it can be seen that the fully corrected thrust rating determined by this procedure is the uninstalled static test bench thrust, corrected for any differences between the testing environment and international standard atmosphere, but not corrected for aircraft installation losses. Just to avoid any doubt here is what the test stand looks like, there is no long intake duct to simulate the engine being installed (and the limited hardware attached to the front of the engine is corrected for).

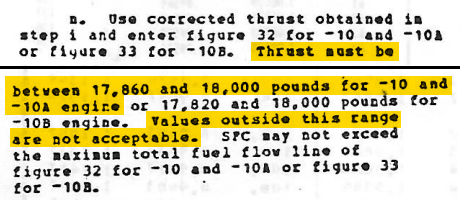

With that in mind let’s see what the manual lists as acceptable thrust limits: 17,860 - 18,000 lbf.

Here is the full section on maximum thrust testing if anyone wants to confirm that I am not lying about the methodology:

In addition the General Engine Description section of the maintenance manual states the J79-GE-10 has a nominal Sea Level Static maximum thrust rating of 17,900 lbf, which exactly matches the value given in the F-4J flight manual.

So to re-cap the J79-GE-10 engine datasheet states the minimum guaranteed maximum thrust rating is 17,859 lbf, a value echoed by the SAC document. The J79-GE-10 maintenance manual states the nominal maximum thrust rating is 17,900 lbf, with an acceptable range of 17,860 - 18,000 lbf (i.e. to be accepted an engine must have a maximum thrust at least 1 lbf higher than the minimum guaranteed value).

So I think we can reasonably conclude that the nominal uninstalled maximum thrust of the J79-GE-10 engine is 17,900 lbf (with an acceptable range of 17,860 - 18,000 lbf). Meanwhile the F-4J manual lists the maximum thrust of the engine as 17,900 lbf. This means that the either:

The F-4J having literally 0 installation losses is not a credible option; therefore the only logical conclusion is that the thrust rating listed in the F-4J manual is that of an uninstalled engine. Now I went a bit overboard proving my point there, but given the allegations against me I felt I had to show that there is sound reasoning behind my belief that aircraft manuals often list the uninstalled thrust of the engine. As I said at the start this is merely one example (with a lot of evidence behind it); there are plenty more examples of manuals quoting thrust ratings that match the uninstalled ratings listed by the manufacturer on datasheets. I therefore believe that you cannot make a declaration that flight manuals always contain installed engine performance.

Also on the topic of regulations and flight manuals I would like to note that MIL-PRF-7700F is the standard which US military flight manuals had to conform to, until its replacement by MIL-DTL-7700 (which I could not find an easily accessible copy of online) in 2002. So although no longer current today, MIL-PRF-7700F is relevant for various aircraft in War Thunder. It does not include a requirement for Section 1 of the manual (the section containing a description of the engine and other systems) to include an installed thrust rating, it only requires “A general description of the development of thrust or horsepower” and a reference to the appendix for aircraft performance data graphs.