- Yes

- No

–

Click to expand

–

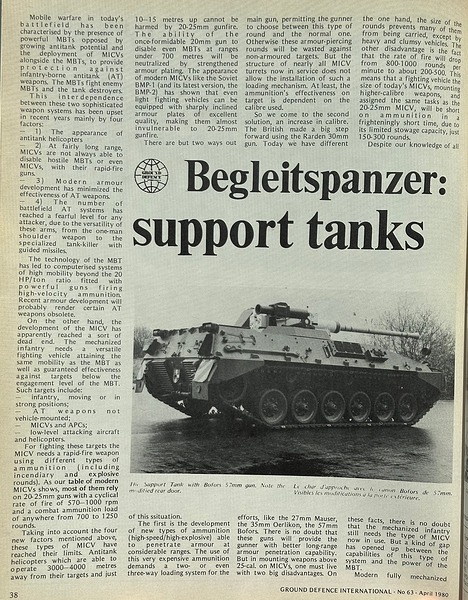

During the mid 1970’s, the bundeswehr’s armoured forces found themselves with a noticable calibre-gap between the 20 mm autocannon of the SPz MARDER and the 90 mm cannon of the Jagdpanzer Kanone. The SPz MARDER itself lacked any sort of anti-tank capabilites until the introduction of the ATGM system MILAN during its’ first “Kampfwertsteigerung” (~combat-capability-enhancement) in 1977.

In this situation, various proposals for upgunning the SPz MARDER were made, proposed cannons ranging from 25 mm to 57 mm in calibre. Among these proposals were such, that intended to bring a new type of armoured fighting vehicle to the mix:

The “Begleitpanzer” (Accompanying-/Support-Tank) or (more formally) “Kampfunterstützungspanzer” (Combat Support Tank), featuring 35-57 mm calibre autocannons and intended to be capable of engaging any threat on the battlefield.

One of such was the Begleitpanzer 57 mm, a joint venture between Thyssen Henschel and BOFORS. A functional mockup was first shown to bundeswehr-officials through extensive presentations in november of 1977. However, despite the weapon-systems’ remarkable results, the bundeswehr declined the introduction of the Begleitpanzer concept back then.

–

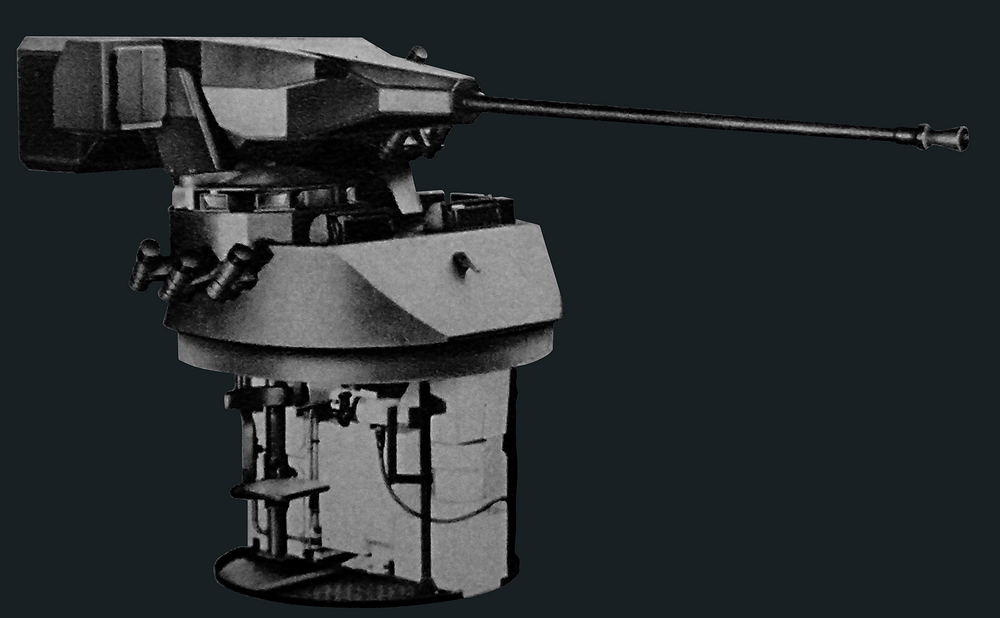

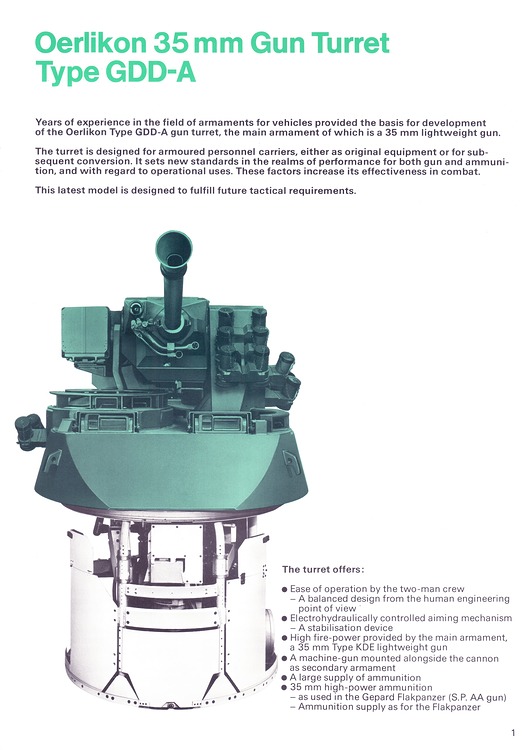

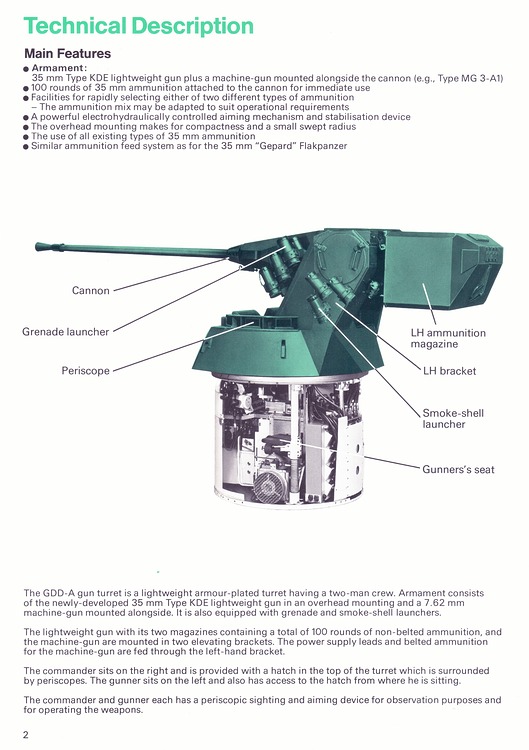

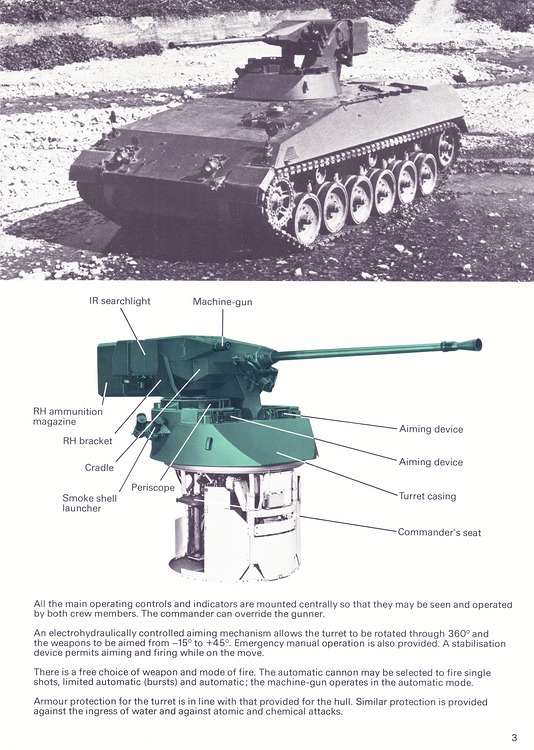

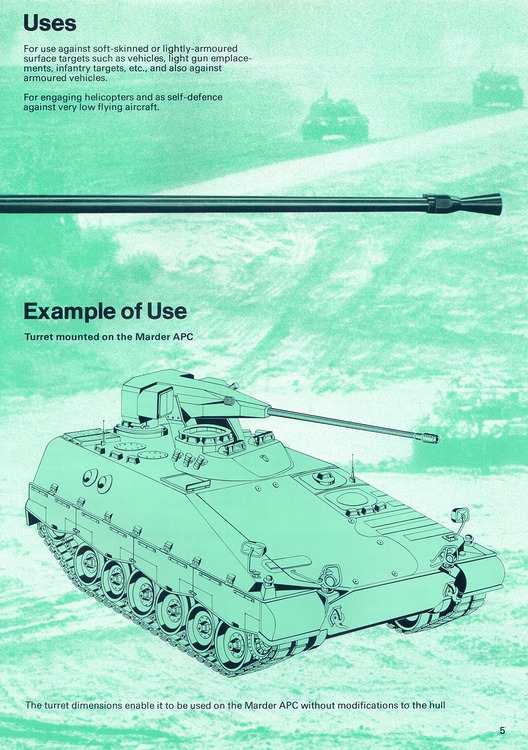

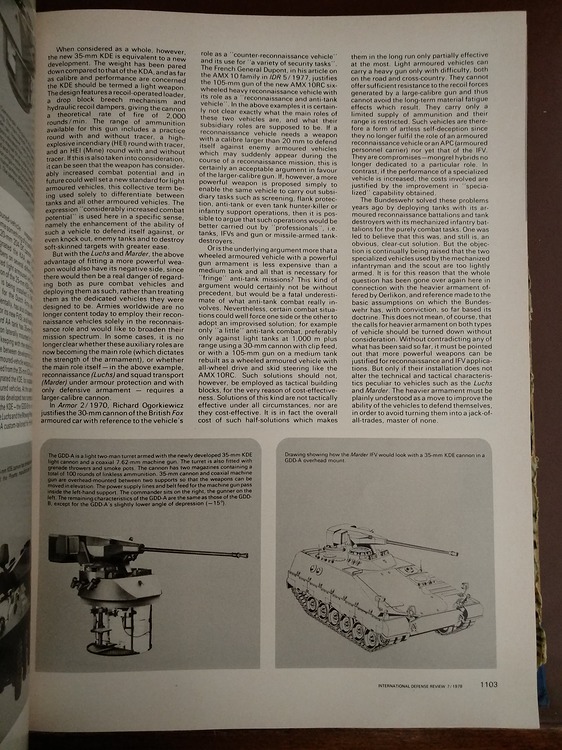

Despite this, Oerlikon continued to work on their own proposal for upgunning the SPz MARDER, which (a.o.) resulted in the GDD-A turret. This turret was to fit the existing SPz MARDER chassis without requiring any major modifications and proposed to replace the currently serviced turrets with minimal logistical effort.

In addition to this proposal of refitting the SPz MARDER, Oerlikon later also offered the GDD-A turret for refitting/repurposing the Jagdpanzer Kanone, which at the time, were slowly being phased out and some retrofitted with ATGM’s. This would involve more severe modifications to the hull and the resulting vehicle itself, unlike the MARDER, which was still to be used as an IFV, would have a different tactical application.

Said tactical application was virtually identical to the concept of the “Begleitpanzer” or (more formally) “Kampfunterstützungspanzer” (Combat Support Tank), due to its’ versatility and foreseen combat-capabilites.

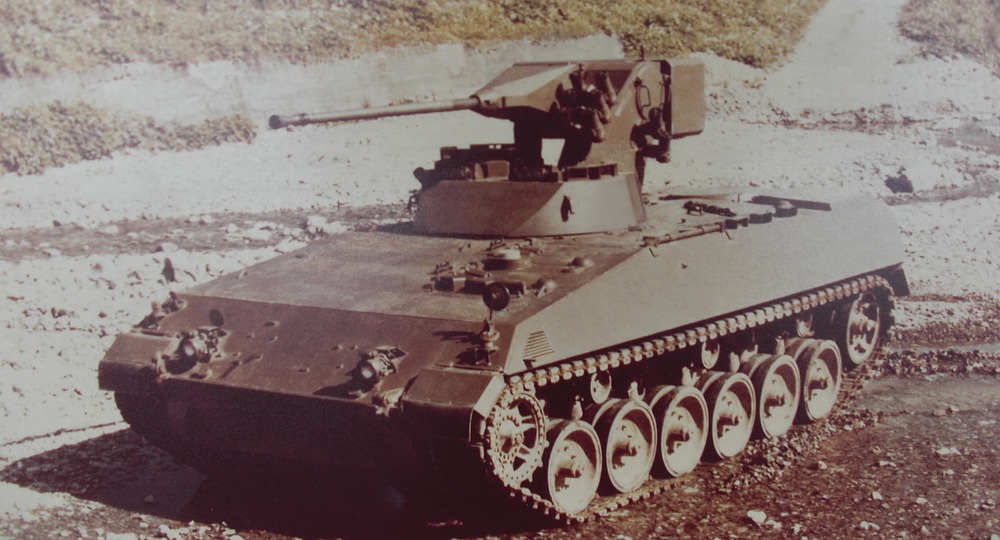

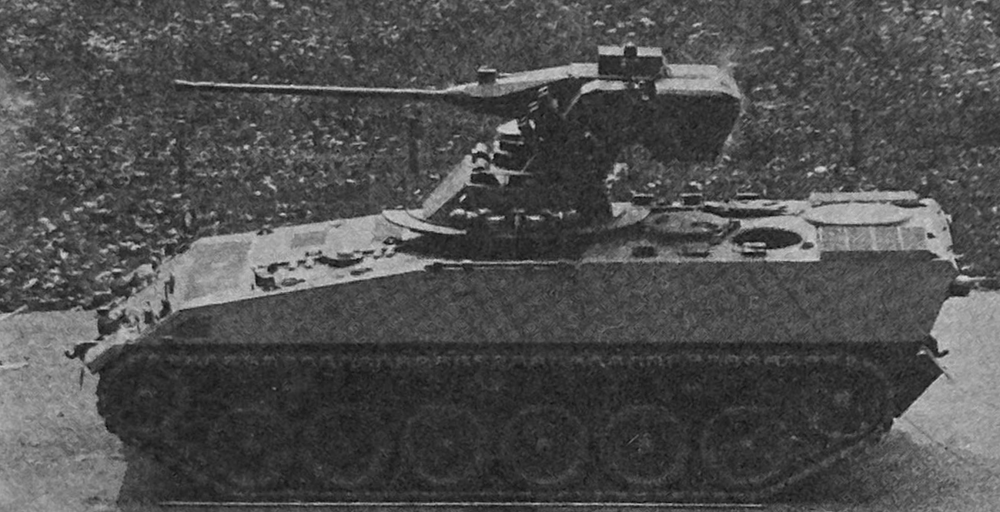

In 1979, the GDD-A turret was fitted to the SPz MARDER prototype RU 362 (built in: 1965) and trialed in 1980 on Oerlikon’s firing range in Ochsenboden (switzerland). However, this new “Begleitpanzer” proposal was also rejected by the bundeswehr, as it did not see any way or immediate necessity to integrate such kinds of vehicles (Begleitpanzer / support-tanks) into their existing structures.

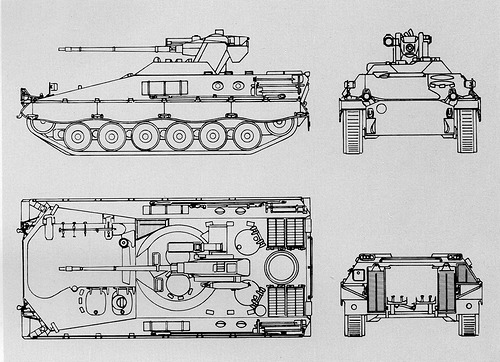

Concept-Drawing of the GDD-A turret mounted on a SPz MARDER (production) chassis

–

History of the RU 362 chassis

The RU 362 (RU = Ruhrstahl) was a prototype of the “third generation” from the development of the SPz MARDER IFV and built/trialed for that purpose between 1965 and 1966.

The original RU 362 prototype featured a two-men turret with a 20 mm auto-cannon, four small roof hatches and six periscopes over the rear fighting-/troop compartment, aswell as a externally mounted MG3A1 above the rear troop-compartment (similar to such mounted on the production SPz MARDER until variant 1A2).

The RU 361-366 prototypes were trialed against the M311-M316 prototypes built by MOWAG in 1966. Near the end of these trails, MOWAG proposed the development of a new chassis with six (instead of the M311-316’s five) roadwheels, which was to utilize the same components as the Leopard 1.

However, the bundeswehr denied this request as it would have lead to additional time-delays.

Thus, in october 1968, the RU 360-series prototypes were chosen as the basis for the pre-production series of the SPz MARDER IFV.

At some point in the late 1970’s to early 1980’s, the RU 362 chassis together with a “Kanonenjagdpanzer Belgienausführung”, later designated ET3/73, were given to Oerlikon for mounting and subsequently trialing the GDD-A turret.

The conversion of the RU 362 was completed and the new GDD-A turret fitted by 1979, one of the most noticable modifications made to the chassis, was the removal of the externally-mounted MG3A1 over the rear-troop compartment.

The modifications required for the ET3/73 were completed right after the RU 362 (Oerlikon GDD-A) finished its’ trials. However, due to the bundeswehr rejecting the introduction of the GDD-A turret, aswell as Oerlikon’s “Begleitpanzer” concept as a whole, the ET3/73 never ended up being fitted with the GDD-A turret and was scrapped soon after.

What happened to the RU 362 chassis after the trials in 1980 is unknown, however it’s likely to have suffered the same fate as ET3/73.

–

General Data:

Click to expand

RU 362 (Oerlikon GDD-A)

Crew: 3

Mass: ca. 28t

Length: 6.73 m

Width: 3.31 m

Height: 2.86 m

Engine: MTU MB 833 EA-500 - 600hp / 441kW (at 2200rpm)

Power-To-Weight Ratio: 21,43hp/t (15,76kW/t)

Transmission: RENK HSWL 183

Tracks: DIEHL 828 A (450 mm)

Suspension: Torsion bar

Armour: ~ 30 mm front, 20 mm upper-sides, 14.5 mm lower-sides, 14.5 mm engine-deck, 14.5 mm rear, 10 mm roof.

–

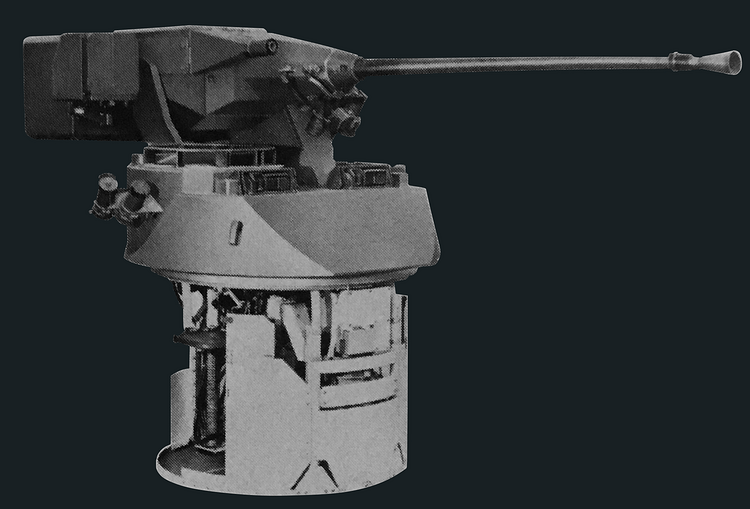

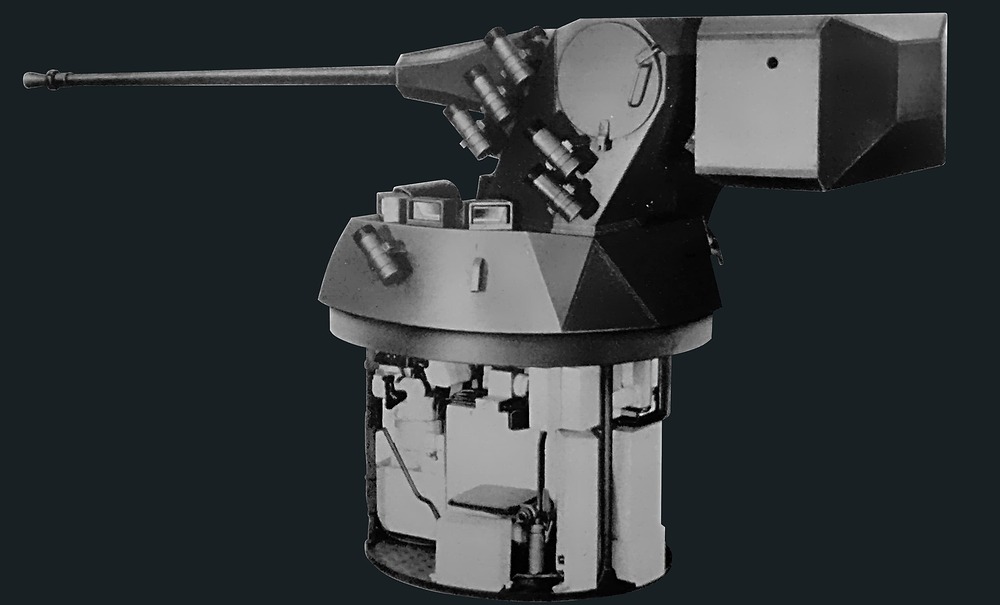

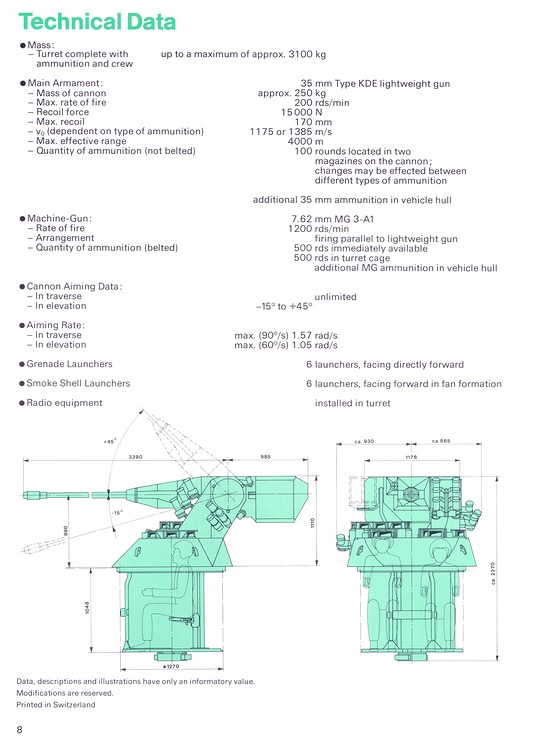

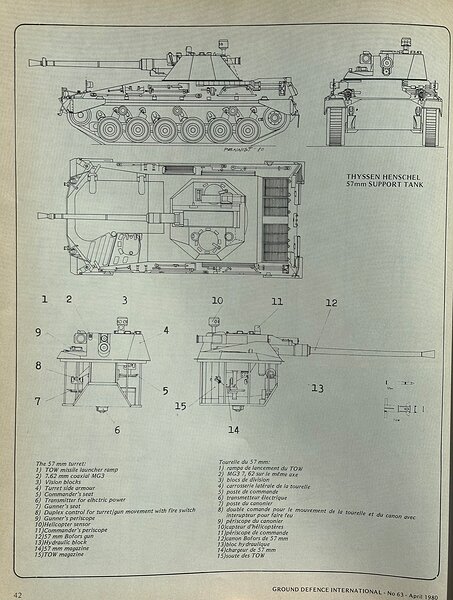

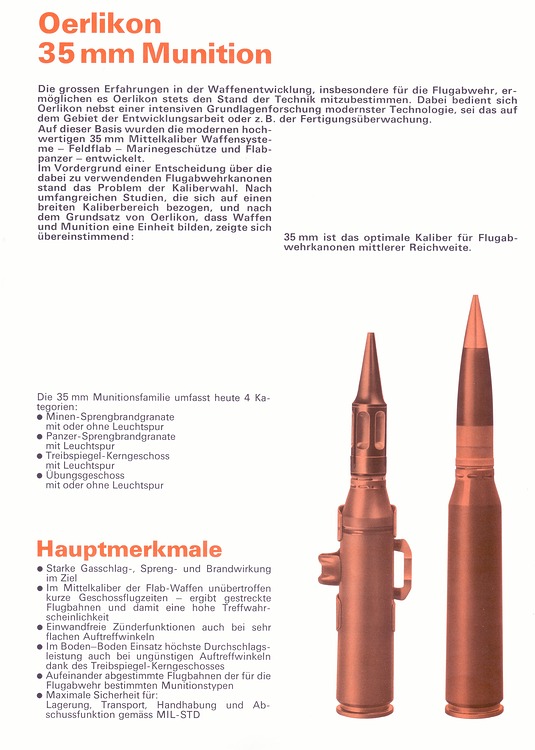

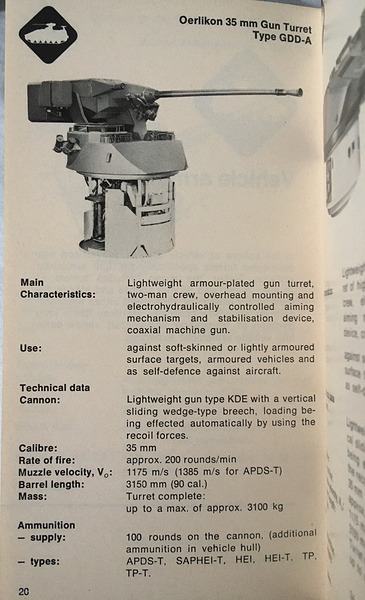

Oerlikon 35 mm Gun Turret Type GDD-A

Click to expand

Mass: 2920 kg (unloaded)

Mass: 3100 kg (fully loaded)

Length (w/ cannon): 4375 mm

Width: 1795 mm

Turret-Ring-Diameter: 1270 mm

Height: 2270mm (1110 mm exterior)

Crew: Two - Gunner & Commander

Armour: Same as hull

Commander-Override: Yes

Primary-Sights: 2x PERI Z11 (2x - 6x magnification)

NVD: 2x Night-Vision-Devices on IR basis, type: BM 8005

Searchlight: 1x IR-searchlight, type: SW 300 (300W)

Vision-blocks: 8x (Commander) + 3x (Gunner)

Dischargers: 10x 76 mm Wegmann (2x/6x/2x) for smoke- or anti-personell charges

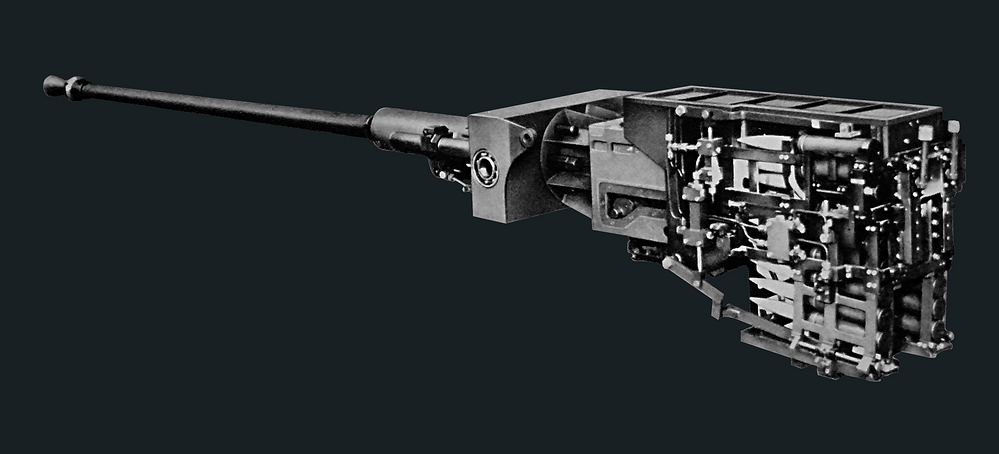

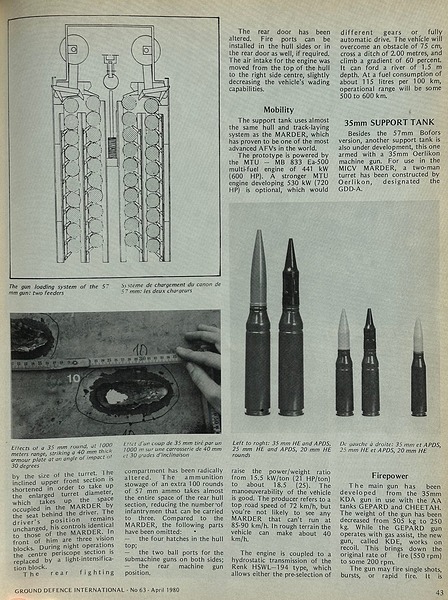

Primary Armament: 1x 35 mm Oerlikon KDE

→ Ammunition-Capacity: 2x50 rounds ready, +approx. 200-400 in hull

Secondary Armament: 1x 7.62 mm MG3A1 (coaxial)

→ Ammunition-Capacity: 500 rounds ready, +500 in turret-basket, +approx. 2000-3000 in hull

Traverse-area (Horizontal): 360°

Limits (Vertical): -15° // +45°

Traverse-Speed: max. 90°/s [1.57 rad/s] (Aim-Speed)

Elevation-Speed: max. 60°/s [1.05 rad/s] (Aim-Speed)

Stabilization: Dual-axis, electro-hydraulic; primary stabilized weapon with slaved optics

–

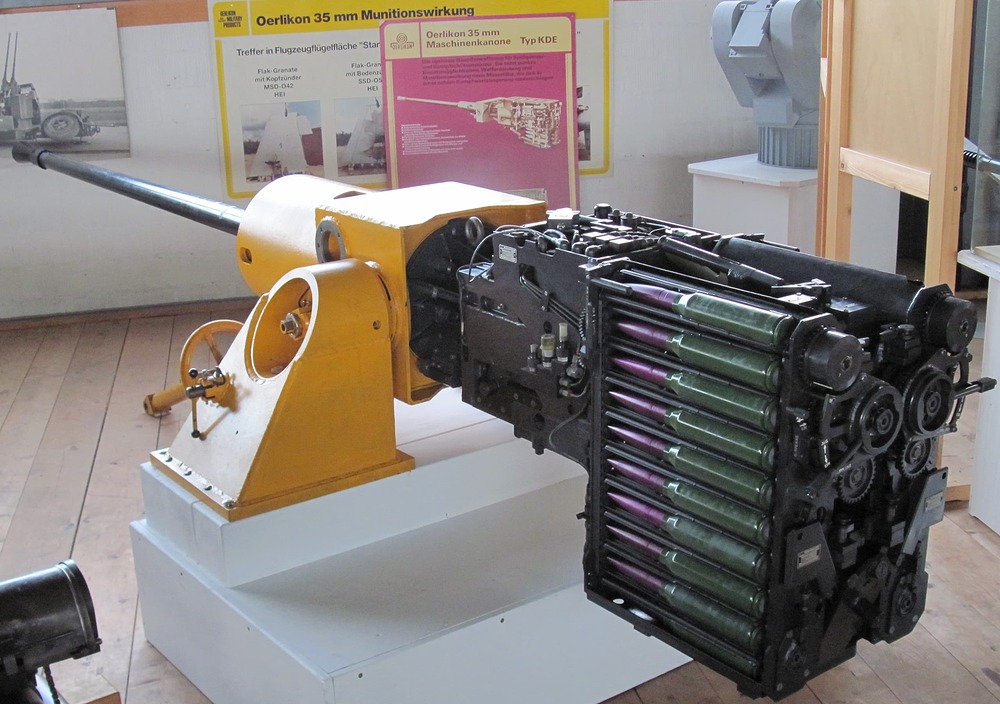

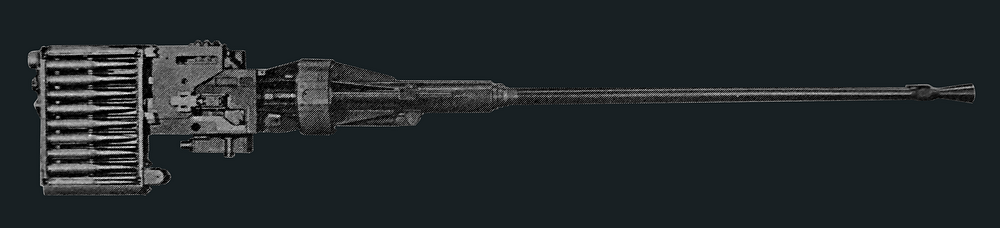

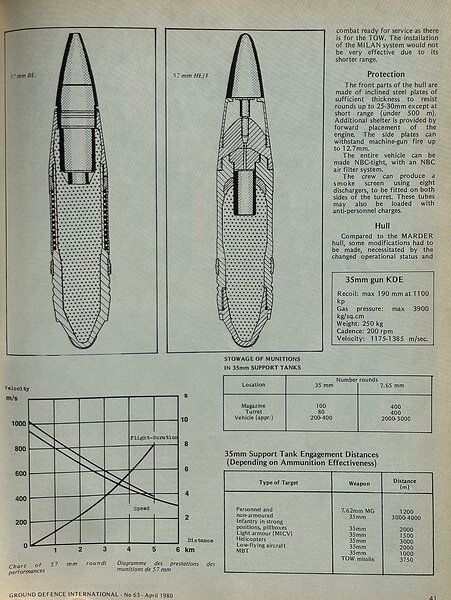

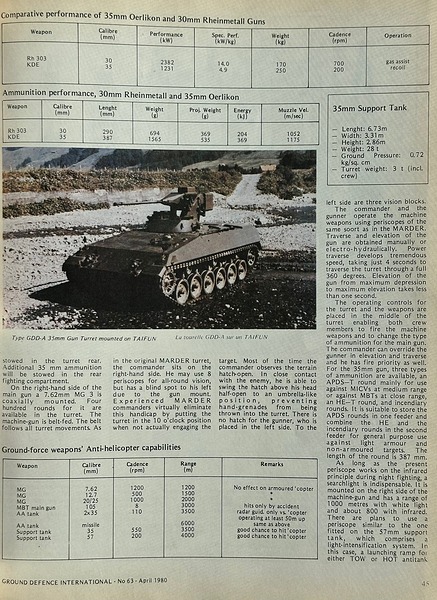

Oerlikon 35 mm KDE lightweight gun

Click to expand

Calibre: 35 mm

Cadence: 200 rounds/min

Cartridge: 35x228 mm

Max. effective range: 4000 m

Bore-length: 90 cal.

Mass: 250kg

Operation: recoil

Recoil force: 15000 N (1529 kg/cm²)

Recoil: max. 170 mm

Gas-pressure: max. 383 MPa (3905 kg/cm²)

Firing-Modes: single-shot or continuous fire

Ready-To-Use Ammunition: 100 rounds (two compartments with 50 rounds each)

Ammunition-type selection: <1s

–

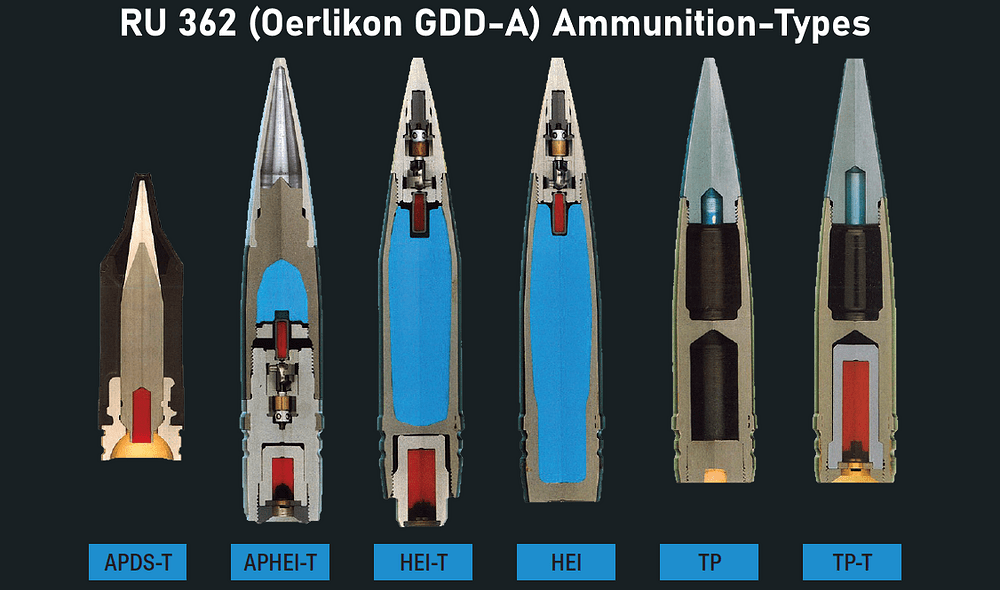

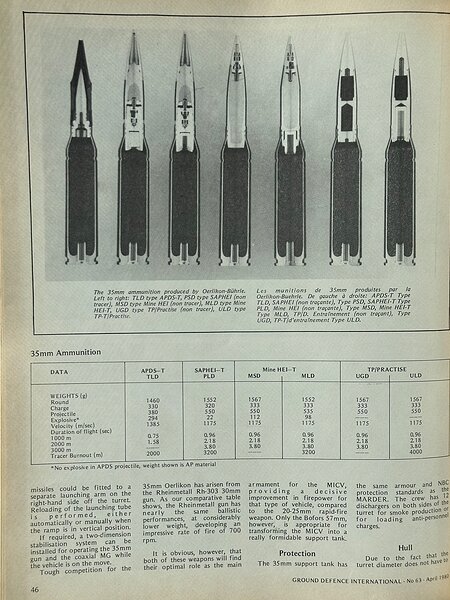

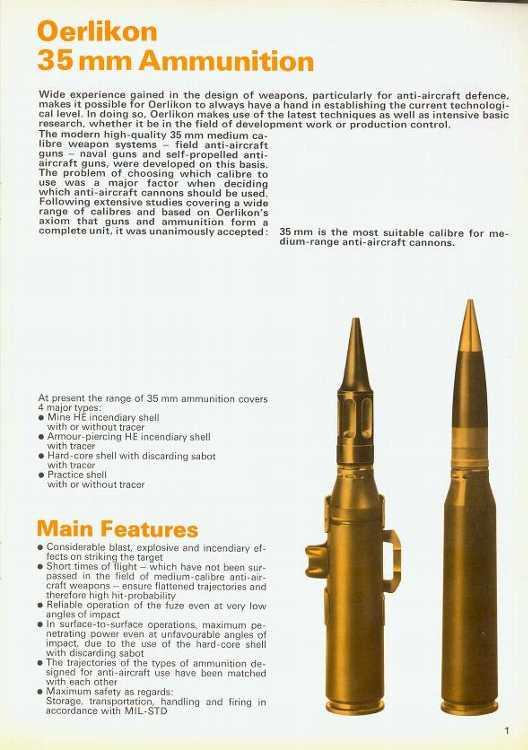

Ammunition-Types & Data

Click to expand

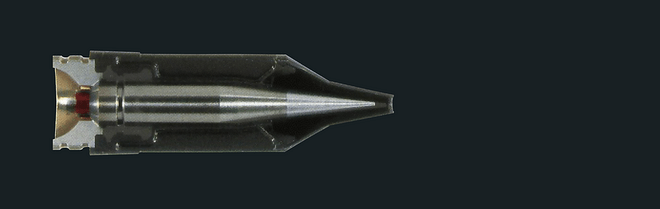

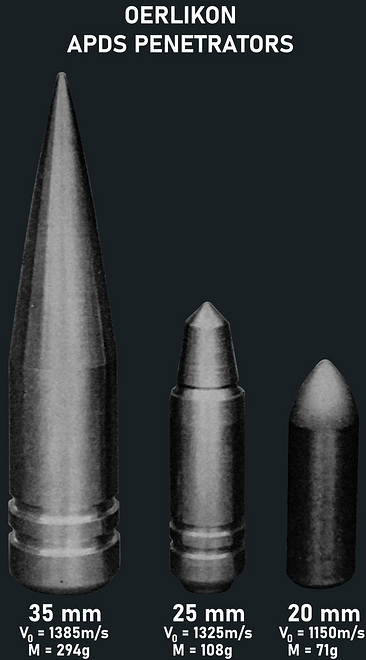

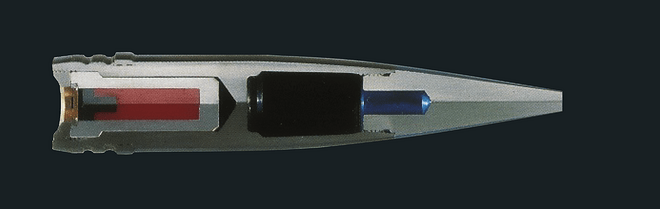

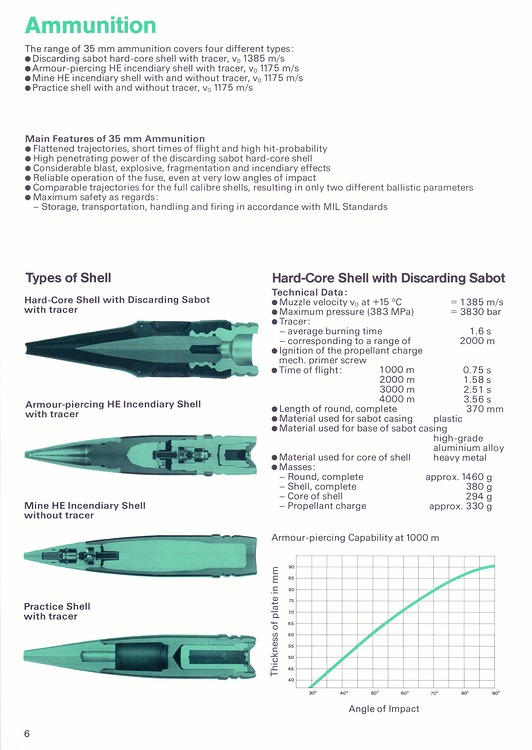

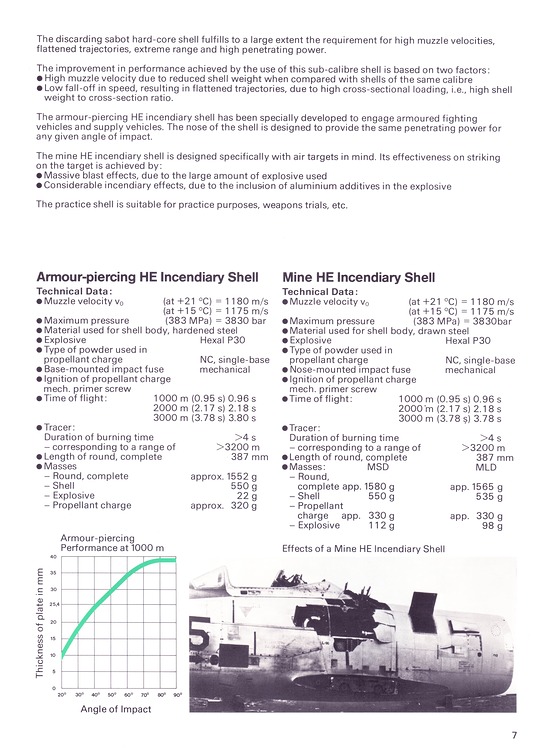

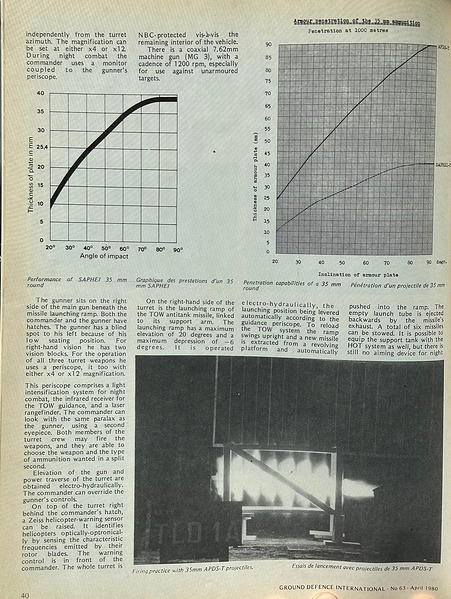

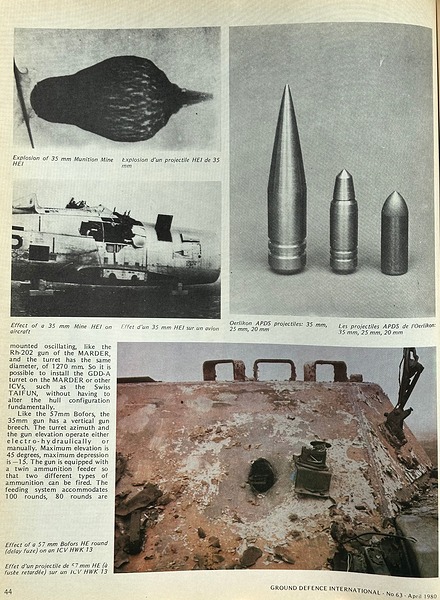

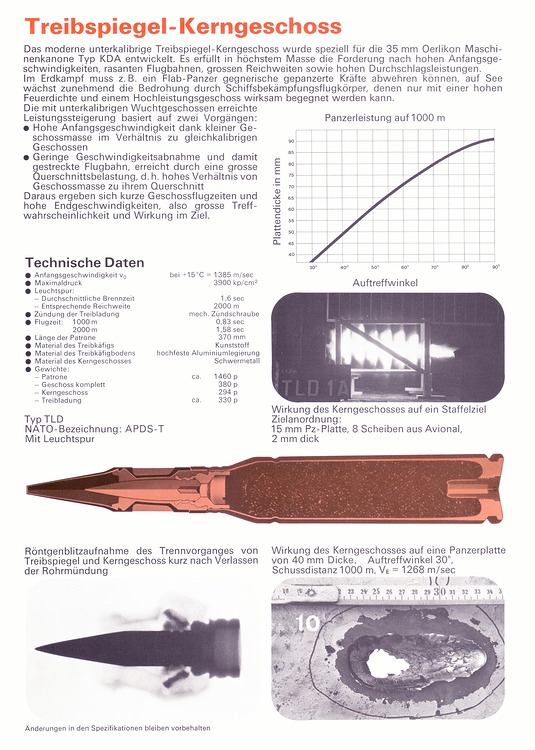

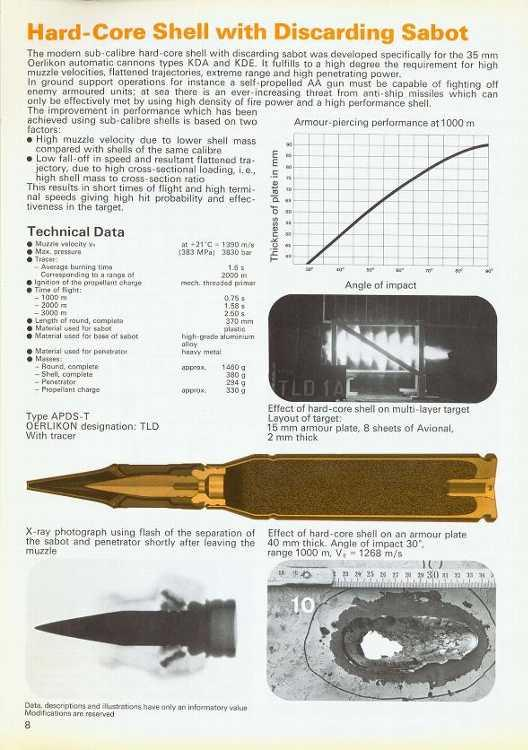

35x228 mm APDS-T (TLD) | DM 23

Armour Piercing Discarding Sabot w/ Tracer

Muzzle-Velocity (V0): 1385m/s

Shell weight: 380g

Penetrator weight: 294g

Tracer-Burnout: 2000m

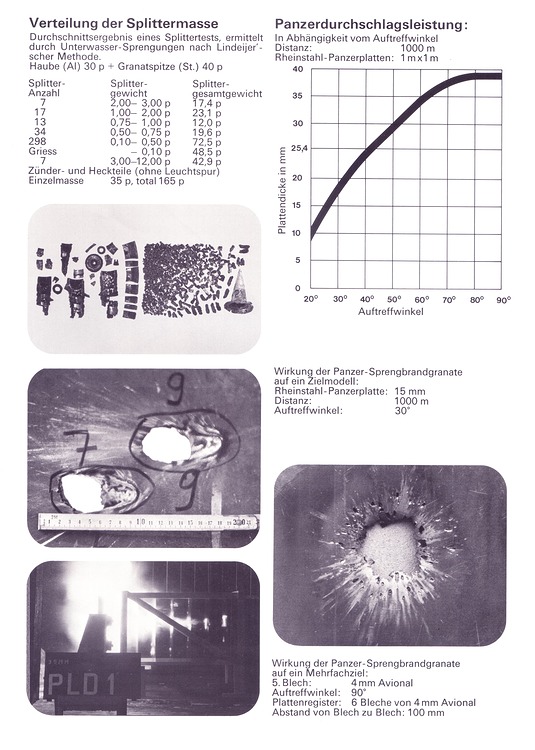

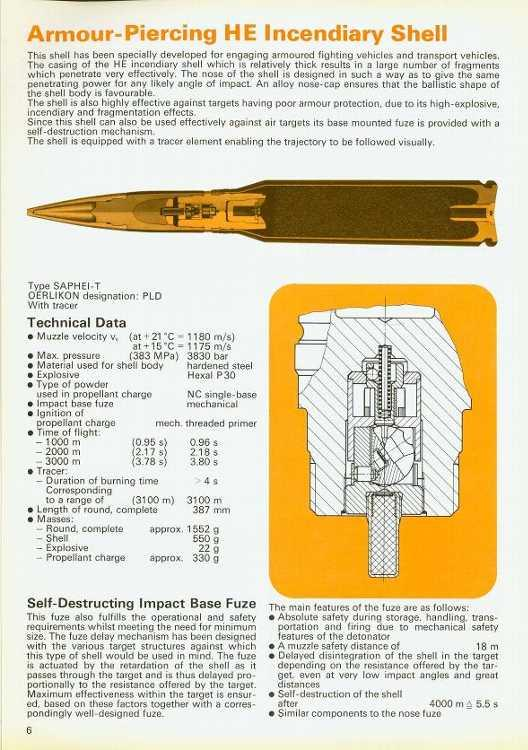

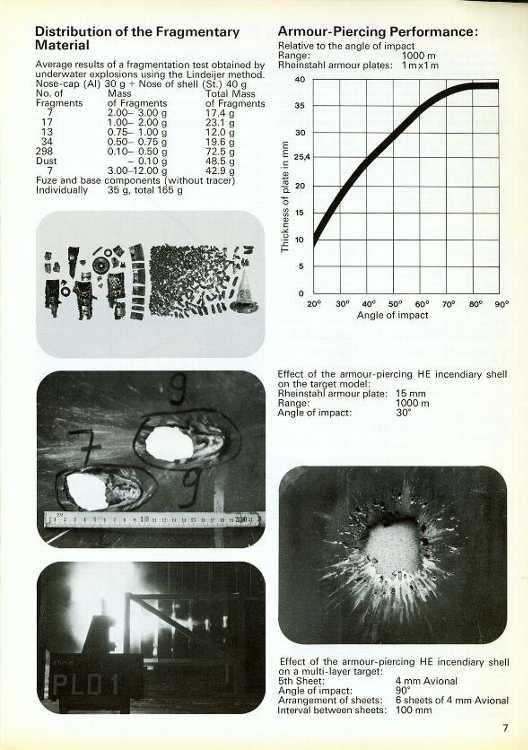

35x228 mm APHEI-T (PLD) | DM 13 A1

Armour Piercing High Explosive Incendiary w/ Tracer

Muzzle-Velocity (V0): 1175m/s

Shell weight: 550g

Explosive Charge: 22g

Explosive Type: Hexal P30

Fuze: Base-Fuze

Tracer-Burnout: 3100m

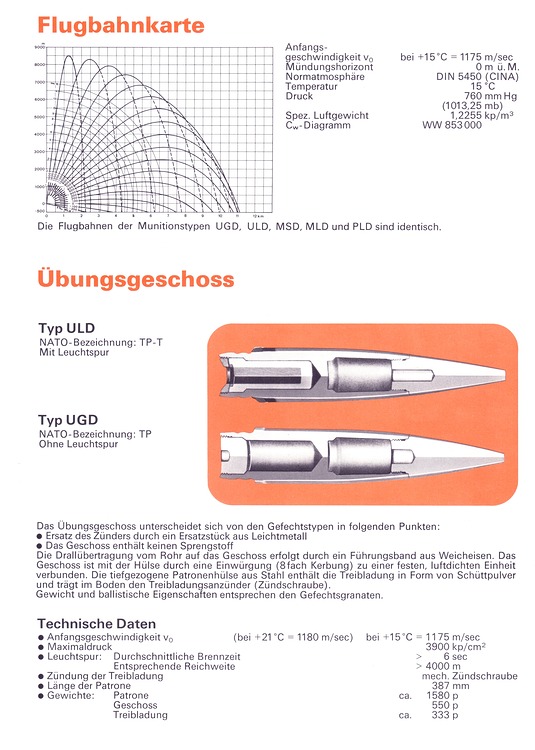

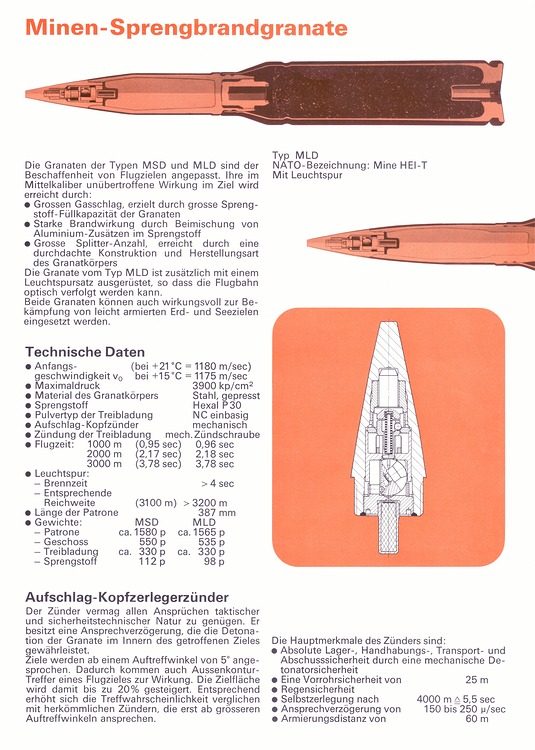

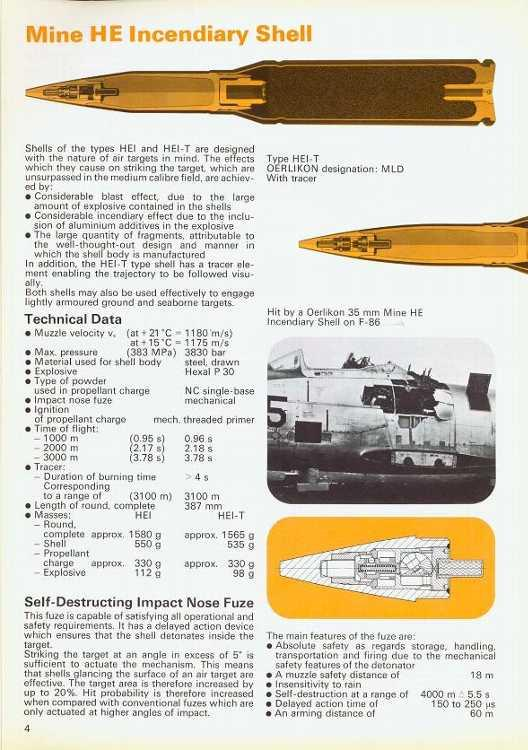

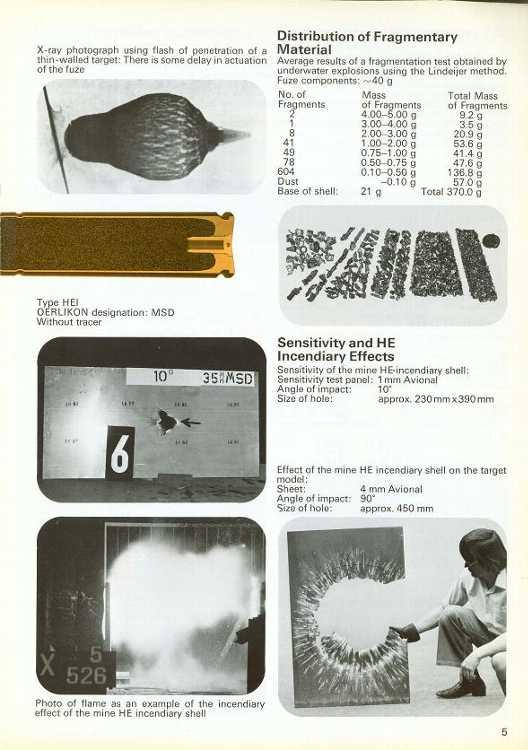

35x228 mm HEI-T (MLD) | DM 31

Mine High Explosive Incendiary w/ Tracer

Muzzle-Velocity (V0): 1175m/s

Shell weight: 535g

Explosive Charge: 98g

Explosive Type: Hexal P30

Fuze: Point-Detonating Fuze

Tracer-Burnout: 3100m

Self-Destruction: 5.5s (4000m)

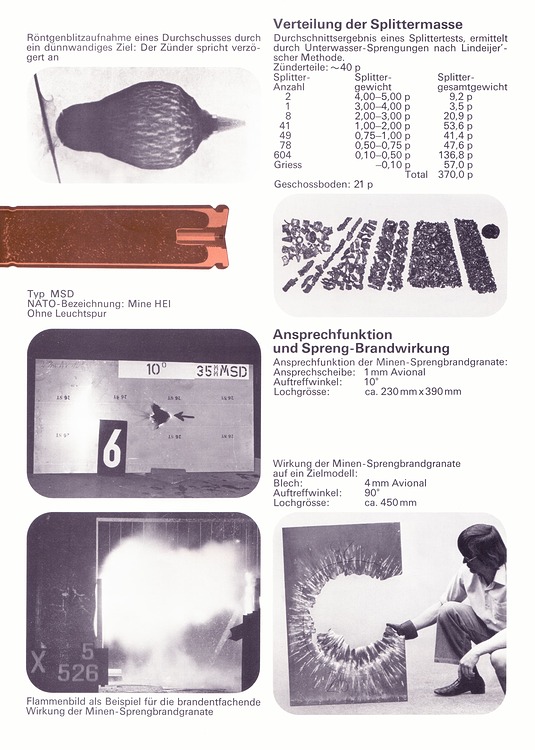

35x228 mm HEI (MSD) | DM 21

Mine High Explosive Incendiary

Muzzle-Velocity (V0): 1175m/s

Shell weight: 550g

Explosive Charge: 112g

Explosive Type: Hexal P30

Fuze: Point-Detonating Fuze

Self-Destruction: 5.5s (4000m)

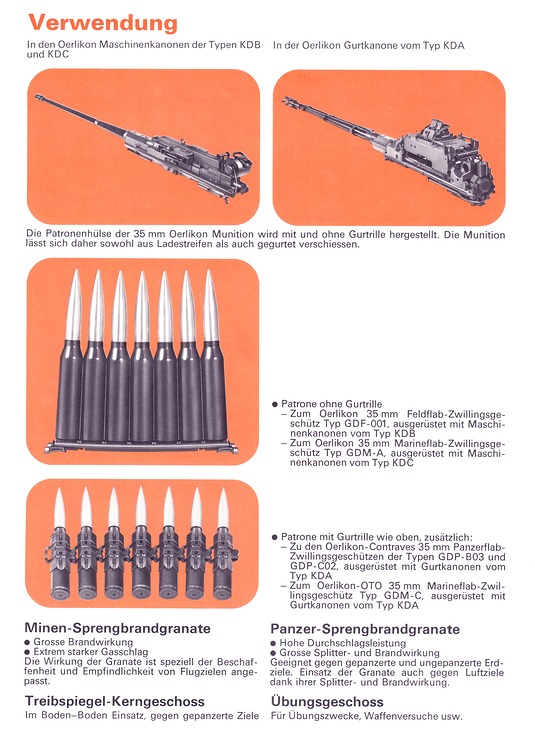

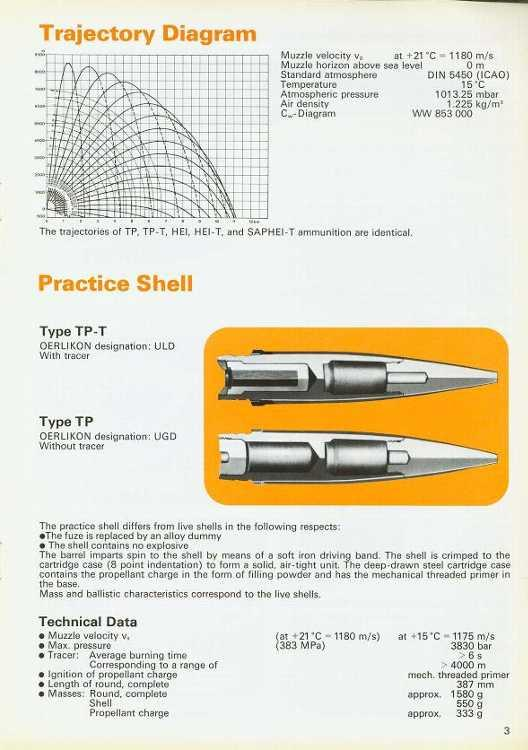

35x228 mm TP & TP-T (UGD & ULD) | DM 18 A1

Target Practice & Target Practice w/ Tracer

Muzzle-Velocity (V0): 1175m/s

Shell weight: 550g

Tracer-Burnout: (ULD) 4000m

–

–

Click to expand

–

–

Click to expand

[S1] Typenkompass - Jagdpanzer der Bundeswehr seit 1956

Publisher: Motorbuch Verlag | Author: Rolf Hilmes

ISBN: 978-3-613-03805-9

Pages: 57 & 58

[S2] Oerlikon 35 mm Gun Turret Type GDD-A (1979)

Publisher: Machine Tool Works Oerlikon-Bührle Ltd.

Full Brochure (Digitized and provided by myself)

High/Full-Res scans (up to 600DPI) can be found here:

(1979) Oerlikon GDD-A Turret - Google Drive

Embed:

[S3] SCHÜTZENPANZER MARDER Entwicklung - Technik - Einsatz

Publisher: Motor Buch Verlag | Author: Hans Peter Lohmann

ISBN: 978-3-613-04693-1

Pages: 22-46 & 192-193

Book-Preview (pages 0-46)

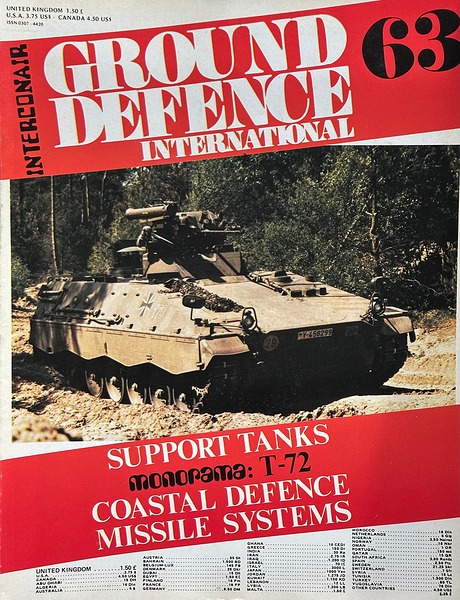

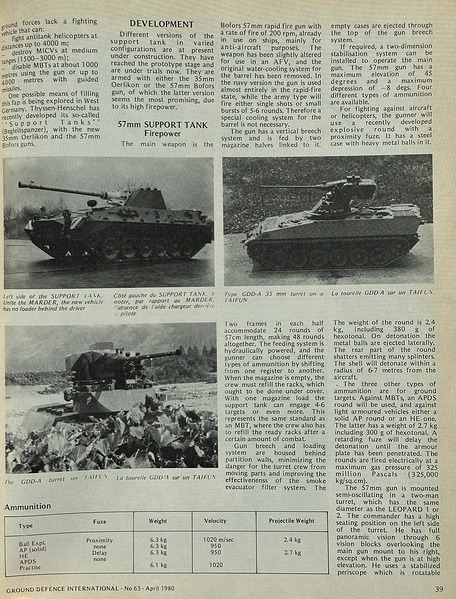

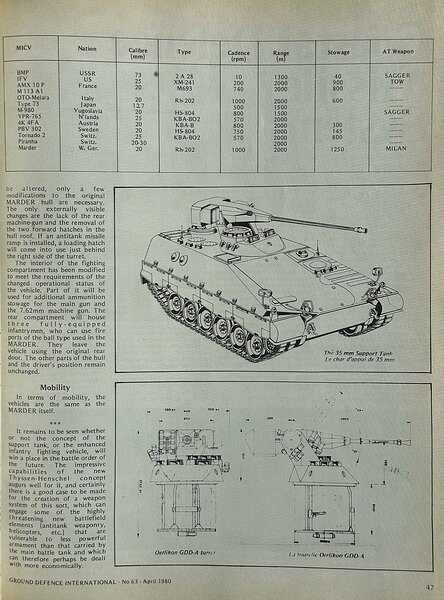

[S4] GROUND DEFENCE INTERNATIONAL - Nr. 63 - April/1980

Publisher: INTERCONAIR | Author: N/A

ISSN: 0307-4420

Pages: 38-47

Digitized Article (Will scan it myself and update the images at a later date)

NOTE: Article misidentifies the hull as a “swiss typhoon”, which it very clearly isnt, it is RU 362 as per Rolf Hilmes book [S1] and visual confirmation.

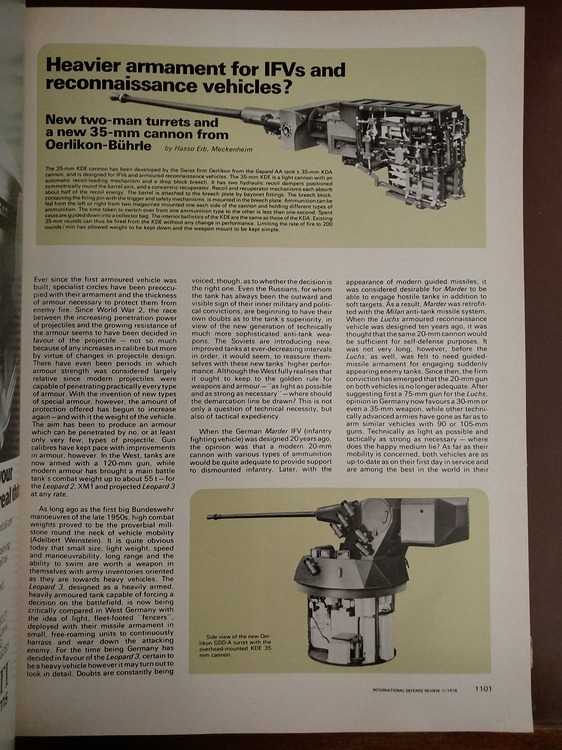

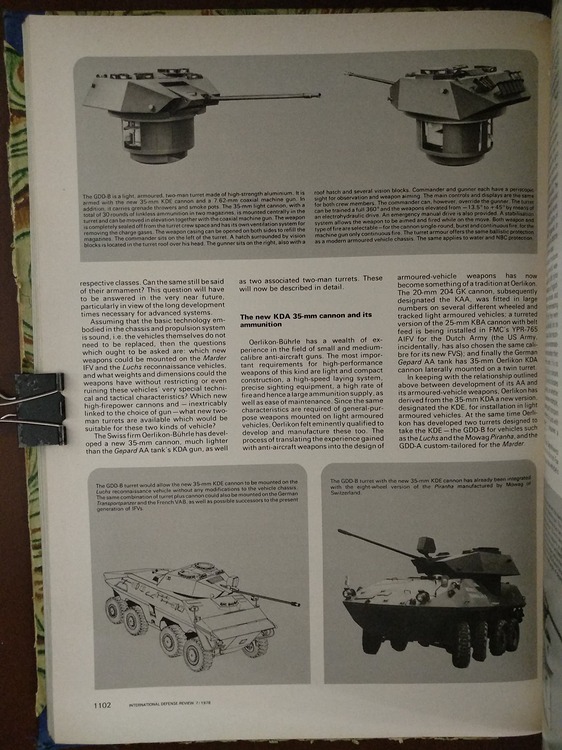

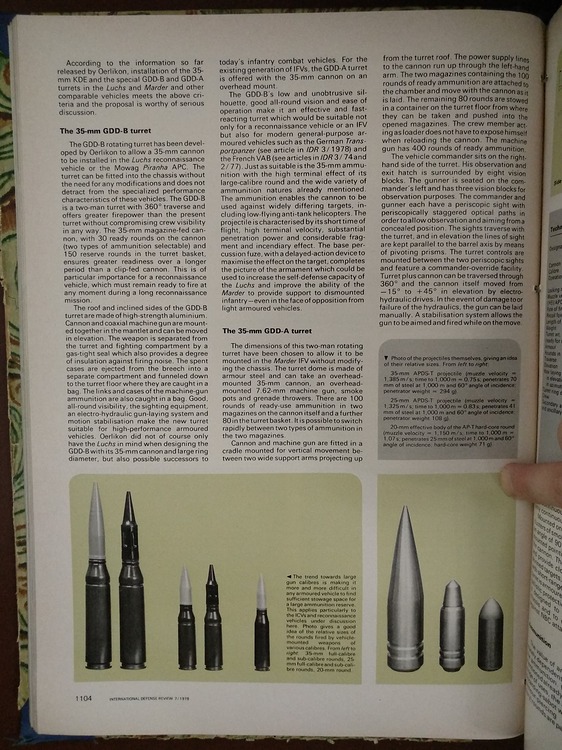

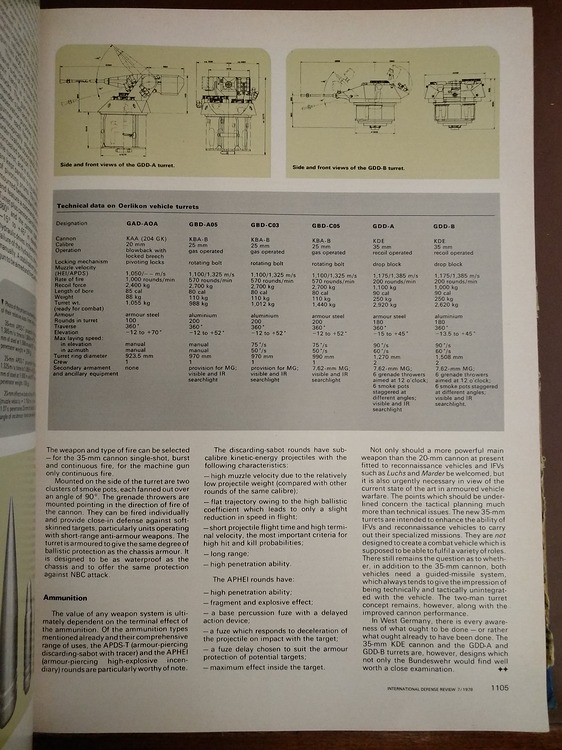

[S5] INTERNATIONAL DEFENSE REVIEW - Vol. 11 - 07/1978

Publisher: Interavia | Author (Article): Hasso Erb. Meckenheim

ISSN: 0020-6512 (SZ)

Pages: 1101-1105

[S6] Oerlikon 35mm Ammunition for the automatic cannons types KDA, KDB, KDC and KDE (1980)

Publisher: Machine Tool Works Oerlikon-Bührle Ltd.

Full Brochure, Note: S7 has much higher image quality!

[S7] Oerlikon 35 mm Munition für die Maschinenkanonen Typen KDB, KDC und KDA (1975)

Publisher: Machine Tool Works Oerlikon-Bührle Ltd.

Full Brochure (Digitized and provided by myself)

High/Full-Res scans (up to 600 DPI) can be found here:

(1975) Oerlikon Ammo (35mm KDA/KDB/KDC) - Google Drive

Embed:

[S8] Oerlikon Military Products for ground / sea / air (1980)

Publisher: Machine Tool Works Oerlikon-Bührle Ltd.

Page: 20

–