History

Combat experience with the earlier B-24D showed that the type suffered heavily in frontal assaults from enemy fighters. Field modifications were attempted to bolster nose defenses, the most notable being the installation of the Consolidated A-6 tail turret into the nose of B-24Ds. This practice began at Hawaii Air Depot and was adopted by other stateside air depots, resulting in a new configuration under a modified designation, the B-24D1.

Encouraged by the success of these field-modified aircraft, the US Army Air Forces made the decision to adopt a powered nose turret as a standard factory feature on production models. This new production-standard aircraft was designated B-24H, and Ford’s Willow Run plant was selected as the lead manufacturer. Ford was supported by Douglas (Tulsa) and Consolidated (Fort Worth), which assembled many of the aircraft using Ford-built components.

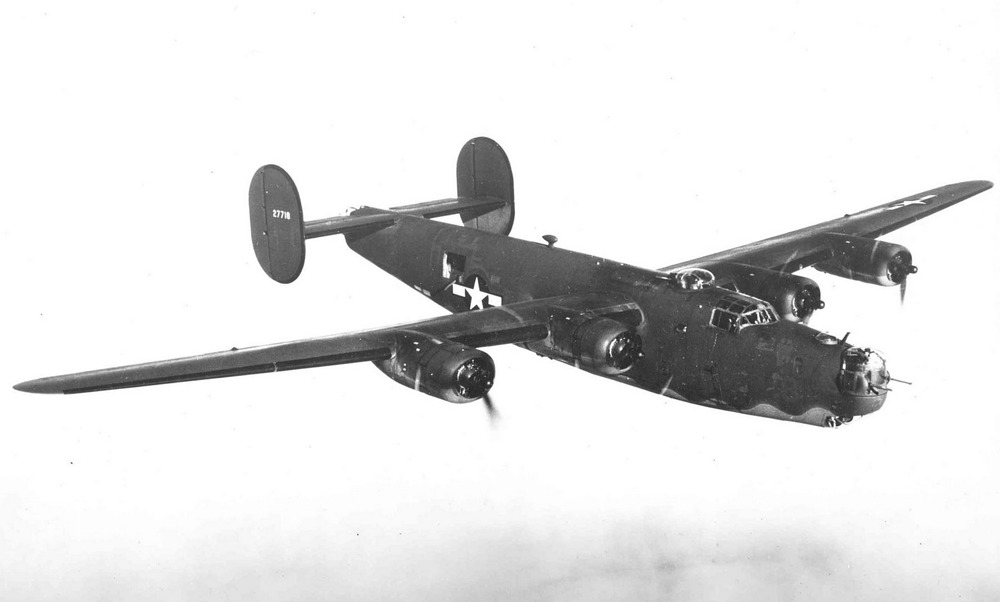

The Emerson Electric Company was tasked with creating a new nose turret for the B-24 based on the design of the A-6 tail turret. Working closely with Consolidated, Emerson developed the A-15 electrically-operated turret, which had a smooth, rounded profile compared to the angular look of the older A-6. To accommodate the turret, the aircraft’s nose structure had to be redesigned, resulting in the characteristic “S”-shaped nose fairing seen on all Ford-built Liberators from then on.

The B-24H was the first Liberator to roll off the factory floor with a powered nose turret already installed, improving defensive coverage against frontal attacks and increasing crew survivability.

To support this turret and other improvements, the airframe required 56 major structural changes over the B-24 airframe. These included a redesigned bombardier’s compartment, outward-opening nose gear doors, and revised internal layouts. Many of these improvements mirrored those seen in North American’s B-24G production line, which was developed in parallel.

Later blocks of the B-24H included additional refinements: the A-6B tail turret, with larger plexiglas panels for improved visibility; a new Martin A-3D “high hat” top turret, replacing the older A-3C model with a taller dome and improved fields of fire; enclosed, staggered waist gunner positions, which prevented interference between gunners and offered better protection against wind exposure; and waist guns were now mounted in K-6 swivel mounts, improving firing stability.

Early B-24Hs were powered by R-1830-43 engines, especially those built at the Douglas plant. Starting with the B-24H-5 block, however, Ford and Consolidated shifted to the newer R-1830-65 engines, which used different carburetors and magnetos but provided improved performance and reliability.

The first B-24Hs were delivered in March 1944, though initial production was slightly delayed due to the required redesigns. Once Ford fully ramped up output, it was delivering a new B-24H every 100 minutes at its Willow Run facility. Final assembly also continued at Fort Worth and Tulsa, using Ford-produced subassemblies.

In total, 3,100 B-24Hs were built:

-

Ford (Willow Run): 1,780 aircraft

-

Consolidated (Fort Worth): 738 aircraft

-

Douglas (Tulsa): 582 aircraft

This made the B-24H the second most-produced Liberator model after the B-24J. The last B-24H rolled off the line in May 1944, after which Ford transitioned to producing the B-24J. B-24Js were functionally similar to the H, though many used the Consolidated nose turret in place of the Emerson due to a shortage. Eventually, all five factories in the Liberator Production Pool transitioned to building the standardized B-24J, many of which later retained the Emerson nose turret pioneered by the B-24H.