Yeah, that would make some sense. Those pesky Germans being slow again :P

maybe we should bribe them to hurry up with a couple of extra brimstones to their new stockpile :)

Threatening to blow up their stockpile with some Brimstones might work :P

It’s not?

DM63A1 uses the same exact penetrator as DM53. It has improved SCBD propellant that deflagrates instead of detonating to reduce ammo cook offs. This propellant actually gives it a marginally lower muzzle velocity of 1720m/s out of the L55 compared to the 1750m/s of DM53.

DM73 would be marginally better, as it increase muzzle velocity to 1780m/s using improved SCBD powder as opposed to the pellets in DM53/63A1 however it is still the same penetrator so the improvement is marginal.

““The DM73 maintains exactly the same penetrator of the DM63 currently in service,” Mr. Henselmann explains, “we worked only on the propulsion system, mainly to increase the combat range rather than to increase performances, as requested by the customer.””

I don’t just mean in terms of raw performance, I’d view it as superior to DM53 as its propellant isnt explosive when hit. That would be a huge buff to any tank carrying it, even if its performance isn’t really any better than DM53 kinetically.

The Challenger 3 could also recieve DM73 ingame, theres no reason it couldn’t for balancing reasons.

Can DM73 be fired by the standard L55 or only the L55A1?

Only from L55A1 due to higher pressure.

So in-game, 2A7V, 2A7HU, and Challenger 3 TD could get it.

There is a fair suggestion that DM53/63A1’s penetrator is using an older tungsten alloy compared to DM63 and DM73.

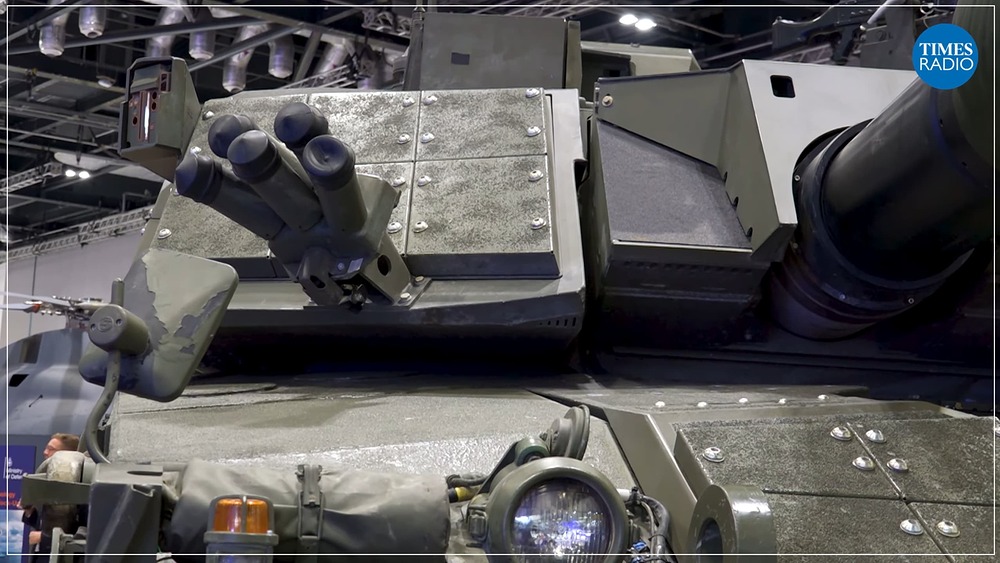

New up close images of Challenger 3 at DSEI 2025

While having around ~140mm of actual physical armor less than both if we’re talking about the hull?

How do you even substiantiate that the base armor is somehow better than 2A7Vs or 2A8s lol.

I mean it’s not hard? I am making some assumptions, but the 2A7 armour scheme is basically the same as the 2A5, with minor upgrades to the hull, so a 1995 design

Which it doesn’t, we have sources confirming the vehicle has received new armor inserts during the V upgrade, and even then, we also know (NOT Y’ALL LMAO) that even older vehicles did in fact have D-technology which was slated for 600 - 650mm KE and that not even the Swedish Trials show the armor levels that 2A5 for example should have ;P

The armour on the UFP is thinner, but also a a steeper slope. The Challenger 3 hull armour is at around 61 degrees, compared to the Leopard’s 53 degrees.

The Challenger 2 achieved around 500mm of KE protection at that slope. The Challenger 3’s ufp is not only a brand new armour type (30 years newer than the CR2), physically thicker AND has addon armour on top of that. It’s not unreasonable for the hull to match the modern versions of the Leopard in terms of effective thickness.

Either way, both tanks likely have enough hull protection to stop the vast majority of threats they could face, the issues arrise more with roof/side protection.

The Challenger 3 appears to have thick roof composite armour which covers the majority of the roof area. Some Leopard variants have this, but it seems to be pretty abscent on the Leopard 2A7 and 2A8 (excluding 2A7.HU)

The Leopard has great armour, but the Challenger 3’s armour is likely reasonably comparable and at around 1/5th the cost per tank, its pretty good.

We won’t really know how much better the new armour arrays are for the Challenger 3 for a while though, so its all speculation.

It being a steeper slope doens’t mean anything due to APFSDS having a better performance at higher angles, on top, Leopard 2s add-on is also at a steepr angle whereas the actual hull is at 53 degrees, meaning the add-on has more LoS volume, but the less steep hull underneath which is 750mm LoS provides better resistance against APFSDS.

The Challenger 2 achieved around 500mm of KE protection at that slope. The Challenger 3’s ufp is not only a brand new armour type (30 years newer than the CR2), physically thicker AND has addon armour on top of that. It’s not unreasonable for the hull to match the modern versions of the Leopard in terms of effective thickness.

It achieved 350mm KE.

Leopard 2A7Vs and 2A8s are also newer than what the CR 2 (350mm) and 2A5 (which in 98% had D-tech hulls providing 650mm KE) had.

Leopard variants have this, but it seems to be pretty abscent on the Leopard 2A7 and 2A8 (excluding 2A7.HU)

The roof add-on is integral part of the 2A8 upgrade, and it will be added to the 2A7V soon, along with MUSS 2.0 soft-kill.

The Leopard has great armour, but the Challenger 3’s armour is likely reasonably comparable and at around 1/5th the cost per tank, its pretty good.

Because CR 3 is a modification of existing vehicles compared to 2A8s that are completely new built, and make use of everything new, including stronger base metals for structural parts.

2A7V tho, for example, was around ~6 mil a tank.

APFSDS penetration is improved relatively at higher angles, but that does not mean a higher angled plate will not provide more protection than a lesser angled one. That however is measured using pure RHA steel armour blocks, not composite armour. Therefore the angled performance of modern composite armour may differ and reduce the effect of normalisation.

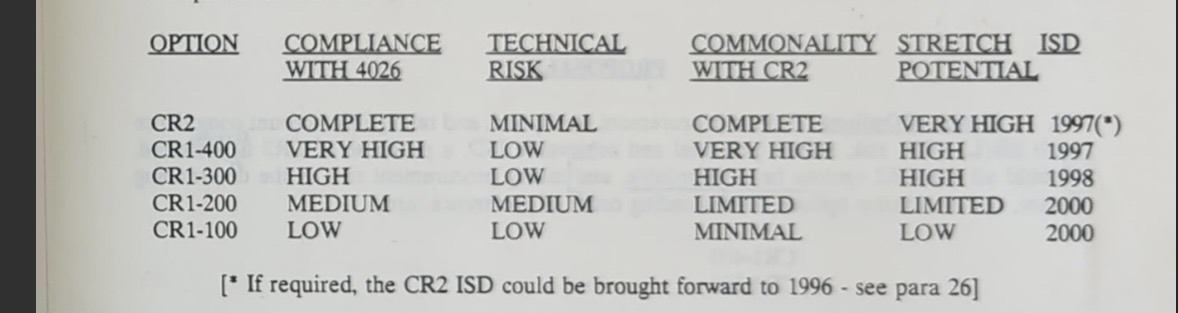

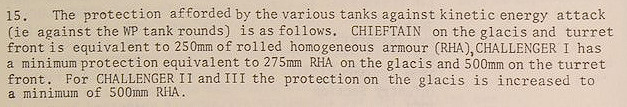

No, SRL 4026 achieved a MINIMUM of 350mm which was a specification for the minimum requirements of the Cheiftain replacement.

SLR-4026 is not a specification for Challenger 2, and 350mm is not a figure for specific armour protection values but rather a minimum requirement. It’s like saying to qualify for a race you must run 5km in 20 minutes, and you claim everyone running the race will run at that exact speed.

CR2 is said to have “very high” stretch potential from SRL-4026, so it’s likely it exceeded that figure.

Gaijin take the 500mm figure for the hull, which would likely be the stretch value from 350mm minimum to meet the protection against the T80U which is listed in other parts of the document.

This also ignores that Challenger 2’s recieved applique hull armour addons later on in life.

We’ve been over this before and I’m going to leave it at that.

It may be, however, the only image I can find of the 2A8 having added roof armour is a digital render rather than a real vehicle.

So as of yet, the vehicle does not appear to have roof addon armour.

From what I can see most places state the 2A7V at higher than 6 million per tank. Unit cost is stated to be around 15 million.

For upgrading older Leopards to 2A7V standard, it was a $760 million dollar contract for 104 vehicles, being at around $7.3 million per tank. Keep in mind, some of these tanks were already at 2A7 standard, so for older variant upgrades, the cost was likely a lot more than $7.3 million per tank.

In terms of completely new built parts, that is true for the Leopard 2A8, hence why it is so much more expensive pushing $30 million for a new tank. However, keep in mind the entire turret of the Challenger 3 is brand new as well as most hull components being upgraded and new (eg. suspension, armour, engine pack). The only thing that is really the same as the Challenger 2 is the hull structure.

It also doesn’t mean an inclination improvement of 8 degrees will somehow overcome a difference of 150mm in sheer thickness.

No, SRL 4026 achieved a MINIMUM of 350mm which was a specification for the minimum requirements of the Cheiftain replacement.

Other parts of SRL 4026 said that 350mm was the figure selected for the hull, however, at least from what I remember.

Even then, say it DID achieve 500mm RHAe KE, we now have German documents stating the new 3rd generation armor for the Leopard 2 KWS was capable of providing 650mm RHAe KE (WITHOUT THE ADD-ONS), and this armor was developed at roughly the same time, so what we’re seeing is that the thickness of Leopard 2s armor very much allows for it to have better armor than the Challenger 2 could have ever had, and this likely translated into both the 2A7V and 2A8 also having better metrics, but at this point that’s kinda 3rd arm measuring since both are likely more than enough protected against anything that can be thrown at them by a non-NATO tank frontally.

CR2 is said to have “very high” stretch potential from SRL-4026, so it’s likely it exceeded that figure.

That stretch was for the turret, as that’s only been what was mentioned, and it was an improvement from 500mm RHAe KE to 600mm RHAe KE, even if we follow this logic, the hull still couldn’t have achieved 500mm RHAe KE, and that number doesn’t even originate from the SRL 4026 but from something else, that was unrelated to the actual Challanger 2 (from memory - it was an upgrade proposal for the Challnger 1 Mk.2 and Mk.3 that never went thru due to technical challenges, instead the opted for steel add-on plates which improved performance to 300 - 325mm IIRC).

Gaijin should honestly re-check the documents.

It may be, however, the only image I can find of the 2A8 having added roof armour is a digital render rather than a real vehicle.

That’s not a Leopard 2A8, that a technical demonstrator on the base of the Danish Leopard 2A7.

For upgrading older Leopards to 2A7V standard, it was a $760 million dollar contract for 104 vehicles, being at around $7.3 million per tank. Keep in mind, some of these tanks were already at 2A7 standard, so for older variant upgrades, the cost was likely a lot more than $7.3 million per tank.

The contract included support packages for each vehicle, strictly speaking the production was less than that.

In terms of pure LOS thickness, a slope of 61 degrees provides around a 22% increase in effective thickness compared to 53 degrees.

That ignores normalisation, but regardless, it is a significant increase. I’m not sure where you’re 150mm of sheer thickness comes from.

We don’t know the exact thickness of the CR3 UFP, but I think around 150mm thicker (from CR2 to CR3 UFP) is a reasonable guess. 450mm at 61 degrees would be in excess of 920mm LOS thickness, so having the potential to easily exceed 650-800mm of KE protection.

I imagine they selected 350mm for SLR-4026 rather than for the actual Challenger 2. I haven’t seen anywhere specifically stating 350mm for the Challenger 2 as a final number.

I’m not arguing that the Challenger 2 exceeded the more modern Leopard variants in terms of hull armour, im just saying 350mm is not a reliable figure for the CR2 hull armour.

I dont know if the extract you send stating 650mm was the one you’re referring to, but I don’t see anywhere it explicitly stating that is excluding the armour addon.

It would be entirely possible to reach 500mm KE protection on the hull, in fact, higher could be achieved. The Challenger 2 hull armour is around 300mm thick in terms of total thickness. At 61 degrees (assuming it is all steel for an example) it would be 620mm+ line of sight thickness.

Therefore even taking into account normalisation and the composite being weaker than RHA, it could still be comfortably 500mm. Add in higher hardness materials etc… 500mm is totally possible. That’s just to prove it is possible, im not using that as proof.

The turret armour figures (500-600mm) are also armour protection at +/- 20 degrees of the frontal turret arc, which would include the turret side armour when at 20 degrees +/-. They are not effective thickness for the turret front head on and shouldn’t be regarded as such.

That is all I have to go off, likewise, the Challenger 3 we have seen is not final. As of yet, the Leopard 2A8 does not have addon roof armour physically fitted.

I imagine the Challenger 3 was the same, as new simulators, ammunition and training equipment has also been purchased.

Which is already taken into account… WE HAVE ACTUAL TAPE MEASUREMENTS OF IT DUDE, we even have technical drawings of Challenger’s upper plate.

Challanger 2s UFP is about ~600mm thick AT 61 DEGREES, Leopard 2s is ~750mm AT 53 DEGREES.

Do you even know that normalisation tends to be greater in MORE SLOPED ARMORS? That is exactly the reason why APFSDS have such high angle performance.

450mm at 61 degrees would be in excess of 920mm LOS thickness, so having the potential to easily exceed 650-800mm of KE protection.

HAHAHAHAHHAHA

I dont know if the extract you send stating 650mm was the one you’re referring to, but I don’t see anywhere it explicitly stating that is excluding the armour addon.

Uh duh, i haven’t even shared everything, but here a great write up:

It would be entirely possible to reach 500mm KE protection on the hull, in fact, higher could be achieved.

Please tell me how “higher” could’ve been achieved when the actual armor maxes out in terms of LoS thickness at ~600mm.

500mm RHAe is already the HIGH END of what would’ve been possible

I imagine they selected 350mm for SLR-4026 rather than for the actual Challenger 2. I haven’t seen anywhere specifically stating 350mm for the Challenger 2 as a final number.

I’ve talked before to people who were the first ones to get their hands on SR(L) 4026 and there was no mention of the MoD selecting anything above 350mm RHAe KE for the CR 2, therefore, tough dude, you’re arguing beliefs now.

That ignores normalisation, but regardless, it is a significant increase. I’m not sure where you’re 150mm of sheer thickness comes from.

I’m talking about just what both the base structures offer WITHOUT add-on armor, if we include add-ons the difference stays relatively the same, as Leopard 2s LoS increases to roughly ~1m for the hull then (slightly less but i dont wanna go look for the actual technical drawing of it rn), and CR 3s add-on(s) look to be about ~150 - 200mm in terms of LoS, so about ~800mm give or take.

- I was never arguing that the Challenger 2 exceeded the Leopard 2.

- The LOS is in RHA, if materials that exceed RHA equivelant protection are used it is still totally possible to hit or slightly exceed 500mm effective. Even with RHA, achieving 500mm accounting for normalisation from 630mm LOS is possible.

I calculated the LOS for you earlier:

CR3 base = ~300mm + 150/200mm addons

450 mm → LOS ≈ 450 / cos61° ≈ 928.2 mm

500 mm → LOS ≈ 500 / cos61° ≈ 1031.3 mm

So assuming the addon thicknesses we seem to agree on, the LOS is somewhere between ~930 and ~1030mm, not ~800mm for the CR3. So not that much thinner, it’s comparable to the Leopard 2.

Sure you may lose some effective thickness to normalisation, but you also stated the Leopard’s hull is slightly less than 1000mm LOS.

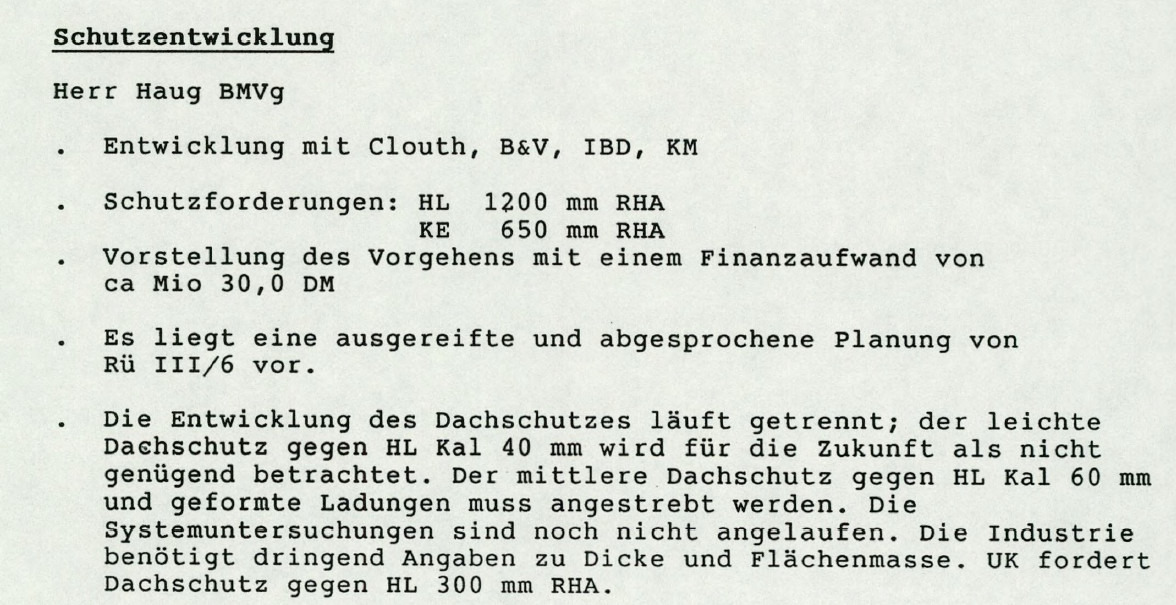

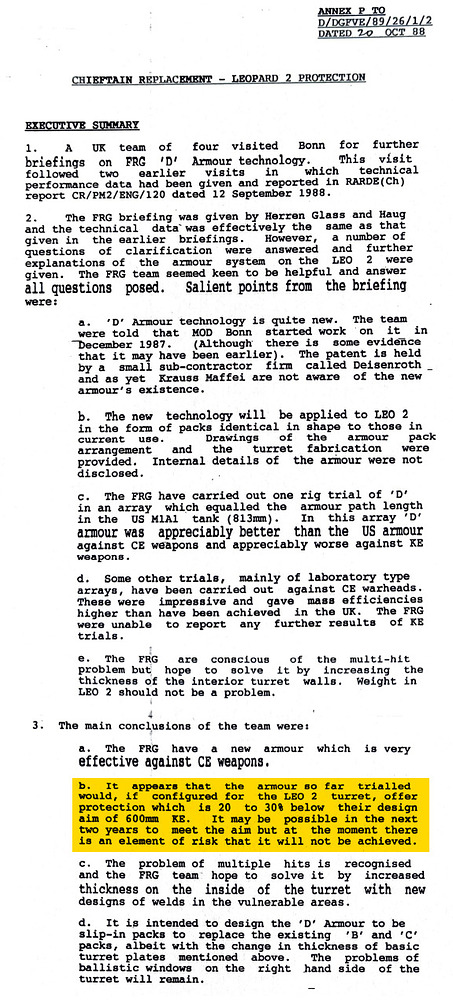

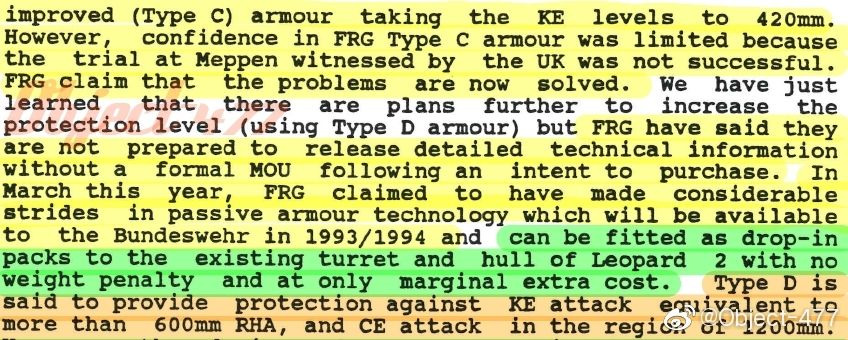

This states >600mm KE for the D-Tech armour, yes it does state 650mm elsewhere, but we do have two different figures. Therefore I think its better to assume an effective thickness of 600-650mm rather than 650mm.

Going back to our original argument. If both offer around 900-1000mm of LOS thickness, so its not unreasonable to say the CR3 could match the most modern Leopards in terms of hull armour.

5 degrees normalisation is reasonable (on the higher end) for a modern APFSDS,

If we assume the Challenger 3 UFP is 1030mm LOS, then you’d get an effective angle of 56 degrees and an effective LOS of 894mm accounting for normalisation. This could be lower depending on the addon thickness.

Apply the 5 degrees normalisation to the 1000mm for the Leopard at 53 degrees (now 48) you get around 900mm LOS, but you said the 1000mm was likely an overestimate, so it could also be lower.

So both could reasonably be around 900mm of LOS accounting for normalisation.

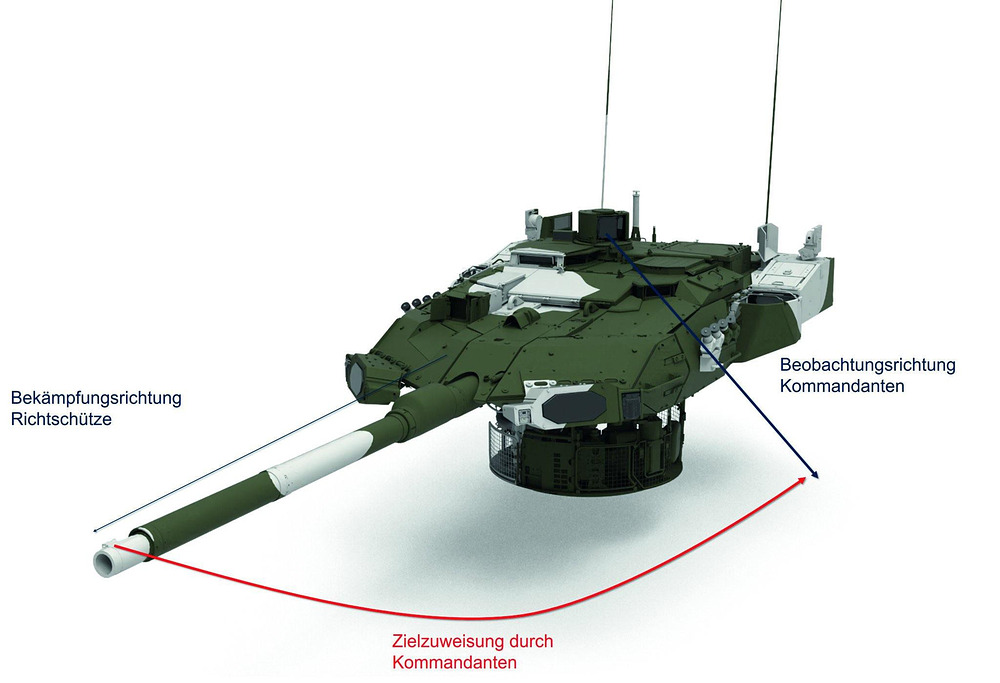

I’m curious about this part of the post:

It should be noted, that 3rd generation armor package as planned & developed at the time was to be fully internal and did not include the later add-on modules defining the shape of the later Leopard 2 models.

However the Leopard 2 Improved as offered to the UK did seem to have some sort of wedges on the turret:

British documents put the turret protection of the Leopard 2 Improved they were offered as 650 mm KE. Before being offered the Leopard 2 Improved they were offered a Leopard 2A4 with fully internal D-Tech armour modules (which appears to be what the post is referring to), and they said it was designed to offer 600 mm KE (though with D-Tech being early in development the Germans had only been able to demonstrate 420 mm KE).

So the impression I had is that a Leopard 2 with internal D-Tech had up to 600 mm KE protection, and whatever wedges they had at that point (not necessarily the final ones) increased that up to 650 mm. Are you able to provide any insight?

This “proposal” looks more like a separate IBD development rather than KM’s, judging by the similarities between it and the later Leopard 2RI/PL, etc.

Germans had only been able to demonstrate 420 mm KE

That was C-technology.

So the impression I had is that a Leopard 2 with internal D-Tech had up to 600 mm KE protection, and whatever wedges they had at that point (not necessarily the final ones) increased that up to 650 mm.

Wedges were added during the definition phase as a way to “lighten” the vehicles for Germany’s fleet of 699 MBTs that could still match D-technology’s armor levels but without the need to change the internal armor modules.

No it was talking about D Tech trials.

The design aim was 600 mm KE. In trials it well 20-30% short of the design aim. That get’s you a protection value of 420 - 480 mm KE. Obviously that was early in development so they may have achieved the full design aim by the time D-Tech was finished, but that’s not really related to my point.

My point is that the post claims that the design aim of 650 mm KE is for purely internal D-Tech turret armour. However all previous information (including the image they used in their own post) has started 600 mm KE was the design aim for internal D-Tech armour (not 650 mm). We do however know that Britain was offered a Leopard 2 with some sort of external armour on it, that had 650 mm KE turret protection. So that to me would imply that the document saying 650 mm KE includes some sort of external armour rather than referring to purely internal D Tech.

JUst gib me Britney Leopard 2!!!