- Yes

- No

- Tech Tree

- GE /Premium/ Battlepass

- No

- USATech-Tree

- UK Tech-Tree

- France Tech-Tree

- Latin american Tech-Tree

- Italian Tech-Tree

- i voted no

Engesa Osório EE-T1 105mm

Introduction:

Spoiler

*Note for those who like osorio,the official name of the osorio has always been EE-T1, and the name EE-T2 was never formally made official, being sometimes used within the company among some of the staff.

The Beginning, Middle, and End of a Good Project and a Bad Deal

In the early 1980s, Brazil had two well-established companies in the military vehicle sector: Bernardini S.A. Indústria e Comércio and Engesa Engenheiros Especializados S.A. Bernardini had specialized in the repowering and modernization of old combat vehicles like the M-3A1 “Stuart” and M-41 “Bulldog” (the latter being somewhat more recent) for the Brazilian Army (EB). Engesa, on the other hand, had gained worldwide fame for developing and manufacturing wheeled military vehicles. Both companies independently embarked on the development of a national combat vehicle, commonly referred to as a “tank.”

Bernardini took the lead and opted for a lighter vehicle, categorized as a “medium combat vehicle,” with simpler systems to make it more affordable for the EB. However, that’s a story for another article. In this one, we will focus on Engesa’s project, which primarily targeted the international market, especially the one dominated by Main Battle Tanks (MBTs). When thinking about the international market during that era, the term “Arabian business” often came to mind.

A Necessity for the Saudis

In 1972, Saudi Arabia acquired an initial batch of 190 units of the French MBT AMX-30. Additional batches were purchased later, along with variations of the same chassis, including a version with a 155mm self-propelled gun (GTC) and an anti-aircraft version with Surface-to-Air Missiles (SAM) called Shahine.

The AMX-30 was developed by GIAT in the 1960s, following the failure of potential French-German cooperation. Despite being produced in large quantities and achieving relative success in the international market, with a dozen countries operating the vehicle, the AMX-30 lacked the status of a state-of-the-art MBT by the 1980s. Technological advancements, such as stabilization systems for the main armament, were overshadowed by the 120mm cannon of the Soviet T-72, already operational in the region by Iran, Iraq, and other countries. The Israeli Merkava also featured a weapon of this caliber.

Beyond technological considerations, geopolitical motivations, such as the Islamic Revolution in Iran in 1979 and the onset of the Iran-Iraq War in 1980, pressured Saudi Arabia to increase its defense expenditures. The country feared losing its regional tank supremacy. In response, the Saudis began evaluating options in the Western MBT market, aiming to select a vehicle operational by the late 1980s.

Engesa’s Opportunity

In the early stages of the project, Engesa executives, who had established positive relationships with several Arab countries, saw the future Saudi tank selection as a chance to enter the armored combat vehicle niche. However, the company lacked experience with tracked vehicles, and its project team was already committed to other programs. Faced with these challenges, Engesa sought an international partnership, initially exploring collaboration with German designers.

Germany, renowned for its tank development, particularly during World War II, produced high-quality vehicles respected worldwide. In the post-war era, the Germans introduced the Leopard 1 in 1965, followed by the Leopard 2 in the 1970s, incorporating improvements and technological advancements. The Saudis expressed interest in acquiring the Leopard 2, but the German government, reluctant to sell to non-NATO member countries, posed a hurdle. Despite the intriguing coincidence of both the Saudis favoring a German MBT and Engesa seeking partnerships with German companies, inquiries in Germany did not lead to collaborations.

Engesa considered alternative options, including discussions with the South African company ARMSCOR. There was a particular interest in ARMSCOR’s production of composite armor. However, due to political issues related to racial segregation in South Africa, a closer partnership did not materialize. After several unsuccessful attempts to find a partner, Engesa made the strategic decision to independently design a combat vehicle, focusing on the international market.

Project Development

To capture a share of the international market for top-tier tanks, Engesa could not cater to the Brazilian Army. This is because the Brazilian Army did not intend to employ a tank weighing more than 40 tons and with a width exceeding 3.5 meters. Moreover, even a tank with exactly these maximum weight and dimensions would still be lighter and smaller than its Western counterparts.

However, as Engesa’s tank needed approval from the Brazilian Army to be sold, it was agreed with the Army that the program would be overseen by military engineers from the CTEx (Army Technological Center).

The project for Engesa’s tank began to take shape in the second half of 1983. It was designated EE-T1 and named “Osório,” a fitting tribute to Marshal Manoel Luis Osório, the patron of the Brazilian Army’s Cavalry. The name “Caxias” (patron of the Brazilian Army) was also considered, but Engesa’s foreign clients would have difficulty with pronunciation.

tests carried out only with the osorio P0 chassis

The future tank was born with the assistance of computer-aided design and manufacturing (CAD/CAM) software, a true revolution at that time. It would be the first time Engesa used these tools in an in-house project. It can be said that the use of software in the development phase helped the Brazilian company design the tank quickly. Time savings were crucial, as Engesa had set a one-year deadline for the project.

The overall design of the EE-T1 was conventional, following the pattern of the major Main Battle Tanks (MBT) of its time: the engine and transmission at the rear of the tank and a crew of four. Separating the crew from the engine/transmission assembly was a structural firewall with thermal-acoustic insulation. The driver sat on the left side at the front of the tank and had his own access hatch. The turret was manned by three crew members, with the gunner and tank commander sitting on the right side and the loader on the left side, above and behind the tank driver. The loader and commander had their own hatches.

A Prince Visits Engesa

In September 1984, the chassis of the first prototype was completed, but none of the turrets had been delivered by Vickers. A quick solution was needed for the vehicle’s presentation because an illustrious visitor was expected: the Minister of Defense of Saudi Arabia, Prince Sultan Bin Abdulaziz, was scheduled to arrive in Brazil the following month. In addition to holding a significant position, the prince was the brother of King Fahd and second in line to the throne. The attention given to the visit was akin to that received by heads of state. The prince spent just under two days in Brasília and headed straight to São José dos Campos, a city that still houses Brazil’s most important hub of the defense industry. In addition to visiting the facilities of Embraer and Avibras, the prince planned a visit to Engesa, primarily to see the Osório.

To ensure they didn’t disappoint him, the company’s technicians assembled a dummy turret and cannon with the characteristics of the final turret, merely to demonstrate the anticipated configuration. The prototype was painted olive green and adorned with the typical emblems of other Brazilian Army armored vehicles. At the end of the visit, no arms deal was concluded, although the Astros II system from Avibras had left a positive impression on the Saudis. The only tangible outcome was the signing of a military cooperation agreement between the two countries.

Osório Visits the Persian Gulf

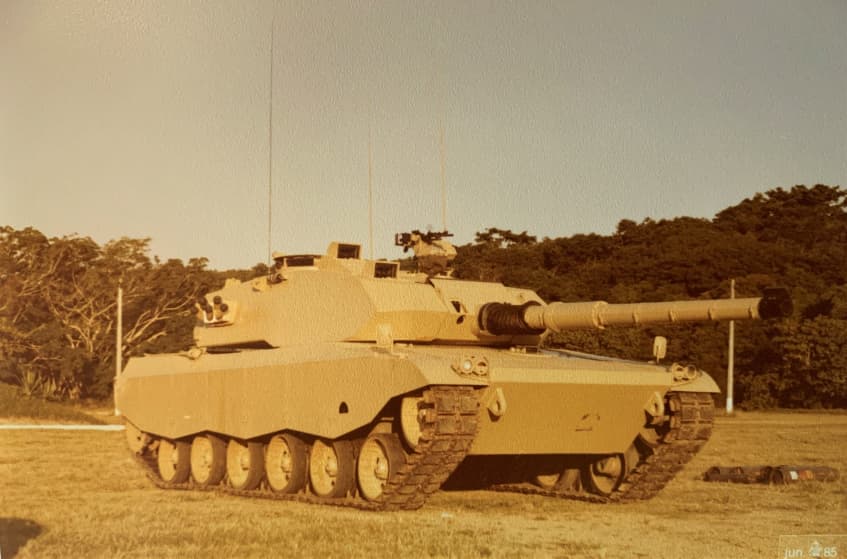

In May 1985, Vickers delivered the 105mm turret, which was immediately installed on the chassis. It was a risky decision since this was not the final turret intended for the competition. The EE-T1 Osório was sent to Saudi Arabia with this turret, transported by a cargo plane that arrived in Riyadh on June 20, 1985. This decision faced significant scrutiny as the tank had undergone limited testing in the country, its configuration was not final, and adapting the vehicle to the environmental conditions of Saudi Arabia was still a relatively unknown challenge.

On the other hand, presenting the prototype to Saudi authorities would be a significant political advantage, showcasing the company’s ability to design and build a top-notch combat vehicle. To the surprise of many, tests and preliminary trials conducted in Saudi Arabia were highly satisfactory. Some deficiencies were identified in the propulsion system manufactured by MWM. Engesa reported the found defects, and MWM made minor modifications to address them.

Back in Brazil, the prototype underwent tests conducted by the Brazilian Army, including trials in the sand dunes of the Marambaia Test Range (Rio de Janeiro state). Based on the demonstrated performance, the Army produced two documents: the RTEx (Experimental Technical Report) and the RTOp (Operational Technical Report). Both were crucial for incorporating improvements.

Prototype Construction:

Spoiler

In 1981, after verifying the accuracy of the adopted requirements, the final decision to begin work on the Osório was approved. Informed, the Brazilian Armed Forces expressed interest in adopting the new tank. The work on both versions was carried out by the private company ENGESA, with the cost covered by government support and financial assistance from the Brazilian government. Although the version armed with a 120mm cannon was primarily planned for export, the possibility of purchasing a smaller quantity for the Brazilian Armed Forces was not ruled out.

From 1982, preliminary work began. A special unarmed vehicle was developed to test the chassis, suspension, and other components. Based on the results of these studies, the design and construction of a prototype armed with a 105mm cannon commenced. In April 1984, ENGESA convened a conference to present a prototype design of the first version of the tank. In the early fall of the same year, it was announced that work on the hull of the first prototype was nearing completion, officially disclosed in October of that year and designated EE-T1. The turret intended for installation on the prototype was designed by the British company Vickers and arrived in Brazil in May 1985, being mounted on the chassis of the first prototype. The designation of the prototype was changed to P1. In 1985, the EE-TI P1 was sent for evaluation in Saudi Arabia and, after tests in Brazil, received positive assessments.

Osório P1 in Saudi Arabia:

Spoiler

In July 1985, the Osório prototype was shipped to Saudi Arabia for pre-selection in a bidding process that initially envisioned the purchase of a thousand main battle tanks under a $3 billion contract. Engesa aimed to demonstrate the existence of a Brazilian tank adapted for desert operations, and the effort was successful, leading to the Osório being shortlisted alongside models from France, the UK, and the USA.

Design and Layout:

Spoiler

The design and layout are identical in both versions of the tanks. The driving systems in both versions are located at the front left of the hull. The driver controlled the vehicle using a control stick and operated pedals, with the right pedal for acceleration, the left pedal for braking, and a parking brake. On the right side of the seat, there was a lever that the driver could use to select the direction of movement or the ability to perform a so-called pivot turn. Next to it was another lever used for selecting the mode, according to the expected speed of movement. The control panel was on the left side of the driver’s compartment. While driving, the driver could see information regarding speed, fuel level, engine RPM, temperature, fluids, etc. When driving with the hatch open, the driver could raise the seat and check a special additional instrument panel. With the hatch closed, visibility was provided by three periscopes. The driver could, for example, drive at night using the passive observation instrument PDP/SS 130, located downstream from the driver. It was expected that in the future, this night observation device would be installed as a thermography-based passive periscope. The driver also had access to an information panel about engine and transmission system failures.

In both tank versions, there were two stations for the gunner and the commander. The gunner’s position was located on the left side of the turret, and the commander’s was on the right. Traditionally, the gunner’s position was below the commander’s. Each had their positions in hatches on the turret roof. The right-side button was common for the gunner and commander, and both hatches opened to the rear. The turrets were developed at the British company Vickers, inspired by the Valiant tank’s turret.

In the rear compartment, the engine and transmission system were located, separated by a fire-resistant door. Both compartments were acoustically insulated. According to some sources, there were hatches for evacuation at the bottom of the hull in both versions.

At the front of the hull were headlights and towing hooks, equipped with lights for night driving and convoy lighting.

Armor and Protection Overview:

Spoiler

In the quest to rival NATO’s contemporary armored vehicles, Brazil’s tank development focused on providing crew protection akin to Western third-generation counterparts. Taking inspiration from the renowned Challenger 1 and its Chobham-style multilayered armor, designers aimed to shield Brazilian tanks and crews effectively against various penetrating measures.

However, achieving Challenger 1-level armor while significantly reducing the tank’s weight proved challenging. Adjustments were made, recognizing that Osório’s armor would be less than Leopard 2, Abrams, and Challenger 1. Nevertheless, key elements of the multilayered armor were retained.

During EE-11 troop transport production, ENGESA employed heat treatment and surface plate saturation. Tank hulls, with an outer layer of hard steel and an inner layer of laminated lightweight and tempered steel, were created. While the troop transport’s armor experience was valuable, its direct application to new tank armor was limited.

Osório’s armor aimed for a protection level akin to Bundeswehr’s 1980s standards, comparable to Leopard I’s latest versions and exceeding the second version of Osório PI. Structural rigidity, vital for impact strength against projectiles and cannon-fired shockwaves, was carefully considered.

Osório’s hulls comprised two-component composite armor plates, with multilayered frontal armor optimizing projectile deflection. The armor utilized steel plates, ceramic plates, lightweight metals, aluminum alloys, and carbon fabric. Both tank versions had shields to protect hull sides.

The tank armor, developed by Brazilian engineers with assistance, possibly from British experts, aimed for Saviour system integration from Racal. This system, detecting laser rangefinder threats, displayed warnings to the commander and driver.

Smoke grenade launchers, incorporated in both tank versions, targeted laser rangefinder opponents. The first version had four 66mm smoke grenade launchers on turret sides, while the second version featured a six-grenade launcher on each side. The P2 tank included a rear turret roof laser radiation detector system.

Engine and Transmission:

Spoiler

Both versions of the Osório tank were powered by the turbo diesel engine MWM 834, also referred to in some sources as MWM TBD 234. This 12-cylinder power unit with direct fuel injection was manufactured by the German company Motoren-Werke Mannheim AG. The cylinder block had a 60-degree spread angle, producing a maximum power of 765 kW (1040 hp) with a displacement of 21.63 dm³. The specific fuel consumption of the Diesel engine was 200 g/kWh. The fuel tanks of the P1 and P2 had a capacity of 1380 dm³, providing a range of over 550 km without refueling.

Ventilators were mounted beside the engine under the roof of the housing. Special attention was given to ensuring the proper functioning of the cooling system, particularly in regions with high temperatures. Experts from Hélice Howden assisted in adapting the cooling system for use in Brazilian tanks. The cooling system had a capacity of 120 liters of coolant.

Despite considerations of the German MTU engine, the MWM engine was ultimately chosen due to arguments emphasizing its durability and reliability, convincing Brazilian decision-makers of its sufficiency for the expected tank mass.

Both engines were equipped with the hydro-mechanical transmission system LSG 3000 developed by the German company ZF, although British transmission systems were also considered. Both systems were used as a dual power transport system. The LSG 3000 propulsion system included a torque converter clutch, main shaft, three rows of planetary gears, and a lateral converter P25000.

Transmission System:

- The system allowed four forward gears and two reverse gears.

- The tanks could execute turns with a radius of B/2, meaning “pivot in place.”

- Tank P2 could accelerate to a speed of 30 km/h in 8 seconds, while P1 could reach 32 km/h in 5 seconds.

- On paved roads, the tanks could travel at speeds exceeding 70 km/h.

Engine Replacement:

- Designers foresaw the possibility of a rapid engine replacement, with well-trained technicians capable of completing the process in approximately 20 minutes.

Braking System:

- The initial braking phase utilized a hydrodynamic brake. When the driver pressed the brake pedal, a special angle in the brake chambers allowed fluid to fill, generating braking torque based on rotor speed differences.

Suspension:

- Both tanks featured hydro-pneumatic suspensions, similar to those used in Challenger tanks.

- Each wheel bearing had a 200 kg actuator cylinder acting as elastic damping elements.

- Suspension deformation was 400 mm, with 330 mm representing dynamic deflection.

- The suspension operated effectively in temperatures ranging from -40 to +50 degrees Celsius.

- The quick return of wheels to their initial positions reduced track ripple, enhancing chassis efficiency.

- The suspension was chosen for its minimal impact on crew, weapons, and equipment vibration.

Track Chassis:

- The track chassis of both tanks consisted of twelve wheels, two tensioners, two drivers, and six upper track support rollers.

- Tensioners had the same structure as support wheels, connected to the tracks with steel bands.

- Each track had 92 cells connected by screws and hooks, capable of enduring over 8000 km.

Fire Control Systems:

Spoiler

Engineers at ENGESA aimed to equip their armored vehicles, such as the Osório P1, with fire control systems comparable to third-generation main battle tanks like Leopard 2, M1 Abrams, and Challenger 1. These systems were designed to reduce aiming time and increase the probability of hitting the target with the first shot.

For the Osório P1 model, the chosen fire control system was the LRS-5 DNLC, manufactured by the Belgian company OIP Instrubel (Oldelft). The system integrated a stabilized telescopic sight with a laser rangefinder and a ballistic computer. Key features of the LRS-5 DNLC system included:

- Telescopic Sight:

- The shooter used a stabilized telescopic sight integrated with the LRS-5 system.

- The sight had a laser rangefinder with a neodymium-immersed rod, allowing distance measurement up to 9995 m with a precision of 10 meters.

- The shooter had a periscope (1x) for observing and detecting enemy targets.

- Aiming Process:

- For stationary targets, the shooter aimed the laser signal at the target, measured the distance, and performed ballistic correction.

- For moving targets, the shooter tracked the target with the laser signal and adjusted for distance and ballistic factors before firing.

- Operational Modes:

- The LRS-5 system could operate in two modes: one where ballistic corrections were made by moving the laser signal and another where corrections were made by moving the cannon.

- Digital Calculator:

- The calculator of the fire control system was initially 8 bits, with sources suggesting a planned upgrade to 16 bits for serial production.

- Calculated angles directed the cannon horizontally and vertically, ensuring accurate targeting.

- Night Vision:

- Night vision for the cannon and machine gun utilized a light amplifier with 6x (or 7x) magnification and a 5-degree field of view.

- The night vision system operated in the near-infrared range.

- Commander’s Role:

- The commander could also aim the cannon using the SCS-5 sight.

- The commander’s station featured a desktop screen (CDB-5) for operating the LRS-5 system.

- Information about environmental conditions and projectile type was input by the crew.

- Additional Information:

- The fire control system accounted for factors like air temperature, wind speed, propellant temperature, altitude, etc.

- Both the shooter and commander received information about the readiness of the cannon to fire.

- Servo-Positioned System:

- The system performed precise line-of-sight tracking through the cannon and could switch to mechanical control in case of sight failure.

- Calculations for four types of ammunition were possible with adjustments for elevation and azimuth.

- Commander’s Periscopes:

- The tower commander had 7 (or 5) periscopes with 180-degree rotation and 2-3x magnification.

Armament:

Spoiler

Osório P0 and P1: The primary armament of the first version of the combat vehicle, P1, originated from the United Kingdom, known as the L7 A3 105mm caliber cannon, with a barrel made of chrome-nickel steel. This cannon design emerged with British Centurion tanks. To achieve a precise projectile speed of 40,000 rpm, the barrel rifling needed to be stabilized at a 9-degree angle. The L7 cannon was chosen for its reliability and applicability to other tanks like the Leopard 1, M1 Abrams, or Type-74.

The cannon could fire the following types of ammunition:

- APDS (Rotating Stabilized) with a mass of 6.5 kg and an initial speed of 1470 m/s.

- APFSDS (Armor-Piercing Fin-Stabilized Discarding Sabot) – arrow ammunition with separate sabot, weighing over 6 kg, and an initial speed of 1500 m/s.

- HEAT (High-Explosive Anti-Tank) with a weight of 10.3 kg and a cumulative initial speed of 1175 m/s.

- HESH (High Explosive Squash Head) with plastic explosives, weighing 11.3 kg, and an initial speed of 731 m/s.

A coaxial machine gun, M60 7.62mm, was mounted to the left of the cannon in both versions. In P1, a FN MAG was also possible. In addition to the gunner and commander, the loader could also operate the cannon. The P1 had a separate ammunition storage area in the turret, increasing crew safety.

Comparation Osorio EE-T1 P1 x Leopard 1a5:

Spoiler

| Osório EE-T1 P1 | Leopard 1A5 | |

|---|---|---|

| Total Length | 10.1 m | 9.54 m |

| Width without armored skirts | 3.20 m | 3.25 m |

| Width with armored skirts | 3.26 m | 3.37 m |

| Height to turret roof | 2.37 m | 2.40 m |

| Weight | 43,700 kg | 42,400 kg |

| Engine | MWM TB 234 V-12 | MTU MB 838 Ca-500 V-10 |

| Power | 1015 HP (746 KW) | 830 HP (610 KW) |

| Transmission | ZF LSG 3000 | ZF 4 HP 250 |

| Suspension | Dunlop Hydropneumatic with height adjustment | Torsion bar system with shock absorbers on the 1st, 2nd, 3rd, 6th, and 7th wheels |

| Tracks | Diehl 570 mm | Diehl 550 mm |

| Fuel Capacity | 1,354 liters | 985 liters |

| Autonomy on asphalt | 550 km | 600 km |

| Main Armament | 01 L7/M68 105mm Cannon | 01 L7/A3 105mm Cannon |

| Secondary Armament | 01 FN M2HB 12.7mm Machine Gun | 01 Hughes X34 7.62mm, 02 Rheinmetall MG3 7.62mm Machine Guns |

| Main Ammunition | 45 rounds | 60 rounds |

| Secondary Ammunition | 3,000 (7.62mm) + 900 (12.7mm) | 5,500 (7.62mm) |

| Fire Control System | Cannon and stabilized periscopes with ballistic computer supported by laser rangefinder | Cannon and stabilized periscopes with ballistic computer supported by laser rangefinder |

| Gunner’s Periscope | Oip LRS 5DNLC (with laser and night vision by residual light magnification) | EMES 18 (with laser and thermal camera) and an auxiliary TZF 1A aiming telescope |

| Commander’s Periscope | Oip LRS-5DN | TRP 2A (with reproduction of images from the gunner’s thermal camera) |

More images and versions that can be put in the game:

Spoiler

EE-T1 Osótio P0 (1985), note the rear exhaust, hollow wheels, smooth-sided tower

Osório P1 (1985) in Brazil, note the side exhaust

Osório P1 (1985) in Saudi Arabia, note the side exhaust

EE-T1 105mm P1 (1987), note the rear exhaust, fins on the cooling system testing for Saudi Arabia

Spoiler

EE-T1 105mm P1 (1988), note the rear exhaust

Technical Data:

Folder:

Spoiler

General Characteristics:

Spoiler

| General Characteristics | Osório P2 (120mm Cannon) | Osório P1 (105mm Cannon) |

|---|---|---|

| Crew | Four soldiers | Four soldiers |

| Weight | 43.7 tons | 41 tons |

| Dimensions: | ||

| - Hull Length | 7.13 m | 7.13 m |

| - Length with Cannon | 10.10 m | 9.36 m |

| - Width | 3.26 m | 3.26 m |

| - Tower Height | 2.37 m | 2.37 m |

| - Ground Clearance | 0.46 m | 0.46 m |

| - Track Spacing | 2.63 m | 2.63 m |

| - Total Track Length | 4.49 m | 4.49 m |

| Armament: | ||

| - Primary | 120mm caliber cannon | 105mm caliber |

| - Additional | 7.62mm caliber machine gun | 7.62mm caliber machine gun |

| - Firing Capacity | 40 projectiles (12 in turret,28 in hul | (40 projectiles, 12 in turret,28 in hul |

| - Firing Capacity with 7.62mm Machine Gun | 5000 projectiles | 5000 projectiles |

| - Firing Capacity with WKM Machine Gun | 600 cartridges | 600 cartridges |

| Propulsion Unit: | ||

| - Engine | 12-cylinder MWM TBD 234 turbo | 12-cylinder MWM TBD 234 turbo |

| diesel | diesel | |

| - Liquid Cooling Power | 765 kW or 1040 hp | 765 kW or 1040 hp |

| - Unit Power Factor | 19 kW/t | 19 kW/t |

| Speed: | ||

| - On Paved Roads | Over 70 km/h | Over 70 km/h |

| - Maximum Reverse Speed | 45 km/h | 45 km/h |

| - Acceleration | 30 km/h in 8 seconds | 32 km/h in over six seconds |

| Fuel Tank Capacity | 1380 dm³ | 1354 dm³ |

| Transmission | Hydro-mechanical ZF LSG 3000 | Hydro-mechanical ZF LSG 3000 |

| - Number of Gearbox Gears | 4 forward, 2 reverse | 4 forward, 2 reverse |

| Suspension | Hydro-pneumatic | Hydro-pneumatic |

Performance Metrics:

- Autonomy: 550 km, with some sources suggesting 500 km.

- Ground Pressure: 0.085 MPa.

- Obstacle Surpassing Capability:

- Trench Width: 3 m.

- Vertical Wall Height: 1.3 m (although some sources indicate 1.15 m).

- Ford Depth: 1.2 m, and after armored preparation - 2 m.

- Slope: 65%, compared to 60% per other sources.

- Side Slope: 40%, contrasting with 30% in other accounts.

Source:

Spoiler

ecsbdefesa.com.br – UMA REALIDADE BRASILEIRA: CARROS DE COMBATE TAMOYO E OSÓRIO

ecsbdefesa.com.br – TANQUE BRASILEIRO OSORIO

ecsbdefesa.com.br – BRAZYLIJSKIE CZOTGI OSORIO

https://archive.armorama.com/features/74/index.htm

Engesa EE-T1 Osório - Forças Terrestres - Exércitos, Indústria de Defesa e Segurança, Geopolítica e Geoestratégia