Type 62 (1962)

Spoiler

The earliest model of the J-7 (before it was named like that) was the Type 62 series, which consisted of Soviet-supplied MiG-21F-13s or kits assembled in China. These models were virtually identical to the original MiG-21F-13 in performance, achieving Mach 2 and utilizing APU-28 missile launch rails for early air-to-air missiles.

(No image available)

J-7 Prototype

Spoiler

The J-7 prototype was the first production model of the J-7 aircraft, manufactured by Shenyang Aircraft Corporation as a copy of the MiG-21F-13. The aircraft’s structure was mostly identical to the MiG-21F-13 but was modified slightly to accommodate production requirements at the factory. Shenyang began limited production of the J-7 prototype in 1967, but production was short-lived and stopped in 1970. A total of 23 units were produced, along with 15 fully assembled aircraft using Soviet MiG-21 parts and the imported prototype. In total, 39 units were delivered to the air force, 12 of which were provided as military aid to Albania. It featured a Chinese copy of the SRD-5 ranging radar, designated CL, with a range of only 3 km—significantly shorter than the original SRD-5’s 7 km range. This radar was primarily used for targeting in air-to-air combat.

J-7 Stability Augmentation System Test Aircraft

Spoiler

Although the J-7 aircraft had sufficient dynamic stability at medium or low altitudes and speeds, it lacked stability during high-speed flight at high altitudes, often experiencing a sudden “nosing down” effect. This oscillation around the aircraft’s center of gravity occurred over a short cycle of a few seconds, making it impossible for pilots to respond effectively using the mechanical control system. This phenomenon not only impacted normal flight but also affected maneuvers during operations, jeopardizing flight safety and degrading combat performance, such as weapon accuracy. One solution was to install an automatic stability augmentation system into the mechanical control system. In 1964, the Xi’an Flight Control Research Institute (Institute 618) developed the 631-type longitudinal damper to improve the J-7’s longitudinal stability during high-speed, high-altitude flight. This analog, single-axis system was China’s first home-developed stability enhancement system for fighter aircraft. Five prototypes of the 631-type longitudinal damper were built, and from 1970 to 1971, they were installed on a J-7 aircraft for validation flights. The tests showed improved damping ratios for the short-cycle modes, indicating enhanced longitudinal stability. However, issues arose with force feedback, leading to uncontrollable behavior. Attempts to address these problems introduced friction damping cylinders, which created excessive control forces, causing pilot-induced oscillations during take-off and landing. Such oscillations could be dangerous, as evidenced by a test aircraft overshooting the runway during landing, damaging its nose wheel. These issues, coupled with technical limitations at the time, forced the suspension of the stability system test after just two flights.

(No image available)

J-7I

Spoiler

The MiG-21F-13, which served as the basis for the J-7 prototype, was designed for high-altitude, high-speed interception but performed poorly in terms of subsonic acceleration and maneuverability at medium and low altitudes. China’s air force needed a fighter capable of maneuvering over battlefields to achieve air superiority, a role that the J-7 prototype struggled to fulfill. Consequently, the air force demanded improvements to the J-7. In August 1968, Chengdu Aircraft Corporation was tasked with developing an improved version of the J-7. In March 1969, the Ministry of Third Machinery issued an official command to Chengdu Aircraft to begin modifications. The improvements aimed to enhance ejection safety, increase armament and ammunition capacity, extend flight endurance, refine stability and control, reduce landing roll distance, improve engine thrust, reduce fuel consumption, lower weight, and extend the aircraft’s service life.

Starting in April 1969, Chengdu began designing and testing modifications for the J-7 based on a “six modifications” plan. This included adding a 30-1 cannon and 60 rounds on the left side of the fuselage to improve close-range firepower, addressing the deficiency of the J-7’s close combat capabilities after firing air-to-air missiles. However, this reduced fuel tank capacity by 100 liters. The canopy was raised by 70 mm to enhance ejection safety and prevent head injuries during ejections, which was crucial given the taller sitting height of Chinese pilots compared to their Soviet counterparts. The intake cone was changed from the original three-stage adjustment to continuous automatic adjustment, optimizing engine airflow under varying flight conditions, improving thrust, and enhancing acceleration during level flight. The intake lip radius was thickened from 0.5 mm to 2.0 mm, improving airflow characteristics during low-speed flight. The aircraft’s powerplant was replaced with the WP-7B engine, featuring high-temperature turbines and hollow turbine blades for increased thrust. The rear wing fuel tank was enlarged, slightly increasing flight endurance.

To expedite development, Chengdu modified a borrowed MiG-21 (serial number 2010) according to the “six modifications” plan, excluding complex changes such as enlarging the rear wing fuel tank. Instead, 480-liter auxiliary fuel tanks were installed under the wings. The canopy adjustment and intake lip radius modifications were also omitted due to technical constraints. The modified aircraft (“five modifications” state) completed its maiden flight in June 1969, conducted by Colonel Wang Ruisheng, and successfully underwent 28 test flights by September. Following the preliminary modifications, Chengdu produced five prototypes with full “six modifications,” completing test flights and static testing by mid-1970. On August 16, 1970, the Ministry of Third Machinery designated this “six modifications” version as the J-7I, later renamed J-7A by the air force. Production began but faced challenges during the Cultural Revolution, including factory mismanagement, manufacturing quality issues, and technical limitations. Of the initial batch of 34 units, none were accepted by the air force due to poor quality, leaving them grounded at the factory.

Efforts to rectify these issues resulted in a scaled-back “three modifications” design in 1973, focusing on adding the fuselage cannon, continuous intake cone adjustment, and thickened intake lip radius. This revised version underwent extensive testing, proving its improved combat and technical performance, including enhanced low-speed thrust and supersonic acceleration. Following successful trials, the J-7I was formally approved for production in 1975. Production continued until 1981, yielding 188 units, including 40 sent to North Korea as military aid.

J-7A

Spoiler

Based on the principle of “not becoming an arms dealer,” China provided military aid free of charge before 1978. Since 1958, the aviation industry had delivered 1,153 aircraft, along with engines, equipment, and spare parts, to 16 countries. However, after 1978, as China’s domestic economic development demanded large amounts of foreign exchange to import advanced equipment and technology, the economic burden of free military aid became increasingly unsustainable. Chinese leaders, shifting their focus to economic development, grew weary of the limited political benefits gained from large-scale free military aid. On January 2, 1979, the central government approved a shift from fully gratuitous military aid to a system that included paid assistance, barter trade, and free aid, depending on circumstances. In line with this directive, on January 18, 1979, the Third Ministry of Machine-Building Industry decided to establish the China National Aero-Technology Import & Export Corporation (CATIC) to manage the import and export of aviation products.

At the time, Egypt urgently needed to replenish its air force equipment following the conclusion of the Third Middle East War. However, strained relations between Egypt and the Soviet Union resulted in the withdrawal of all Soviet experts and the cessation of Soviet military aid. Given Egypt’s amicable relationship with China, the Egyptian government requested aircraft, engines, and spare parts from China in January 1979. After multiple negotiations, Egypt understood and agreed to China’s transition from free aid to paid trade. On April 5, 1980, CATIC and the Egyptian Ministry of Defense signed a contract to export 60 J-7 aircraft along with spare engines, parts, and testing equipment, with a total value exceeding $200 million. The aircraft Egypt purchased were modified from the J-7I variant according to the Egyptian Air Force’s requirements and were designated the J-7A (exported as the F-7A in line with Western fighter-naming conventions).

The J-7A, tailored to Egypt’s specifications, was equipped with the WP-7B engine, which had increased thrust and an extended service life. The engine’s first overhaul interval was doubled from 100 to 200 hours. Similar to the later versions of the J-7I, the drag chute compartment was relocated to the base of the vertical tail. Some electronic equipment was replaced to meet export requirements, including upgrading the CL-2 radar rangefinder to the improved 222 radar rangefinder and replacing the YD-3 friend-or-foe identification system with the export-specific 602 model. The XU-1 500-liter fuel alarm system and Hangjia 11-10 gun camera were removed, and all aircraft markings were changed from Chinese to English. By the end of 1981 to early 1982, Egypt received the first batch of 20 J-7A aircraft. These J-7As, along with the MiG-21s already in the Egyptian Air Force, became Egypt’s main fighter aircraft. Later, as Egypt’s relations with the United States and Western nations improved, the country acquired more advanced F-16 fighters. Consequently, the J-7A and MiG-21 aircraft were either retired or sold to countries like Iraq.

J-7 Target Drone

Spoiler

With the development of China’s air force weaponry, subsonic target drones like the “Chang Kong-1” and the MiG-15-derived Tu-5B unmanned target drones could no longer meet the evaluation requirements of third-generation air-to-air missiles, which required supersonic targets capable of speeds exceeding Mach 1.5. As a result, the Air Force Aviation Testing Center began developing supersonic unmanned target drones. Since the J-7I aircraft had deficiencies in both performance and safety and were gradually being retired with the introduction of more advanced J-7 variants, these retired aircraft were modified as aerial targets for live missile testing. In October 1990, the Air Force Aviation Testing Center officially initiated a project to convert retired J-7I aircraft into supersonic target drones.

The converted supersonic target drones retained the same dimensions, structural strength, radar signature, and infrared characteristics as real fighter jets, allowing them to accurately simulate combat environments. This provided a realistic evaluation of missile seeker performance, warhead effectiveness, and overall missile accuracy. Moreover, the modified drones were inexpensive, reusable, and cost-effective.

The conversion process involved removing the original manned systems, flight instruments, communication and navigation systems, and weapon control systems. A newly designed analog automatic flight control system was installed, enabling full authority control for high-speed operations. The system could autonomously calculate navigation routes and ensure automated taxiing, supersonic flight, and autonomous landing. Additionally, specialized target equipment, such as telemetry, remote control systems, and miss-distance indicators, were added. The hydraulic and cooling systems of the original aircraft were also modified. In 1998, the unmanned target drone, based on the J-7I, completed design finalization, meeting all required specifications and filling a domestic gap in supersonic target drone capabilities. It received the National Science and Technology Progress Award (Second Class) in 2000.

J-7II

Spoiler

The J-7II was developed to address the shortcomings of the J-7I, which failed to meet the initial expectations and had major deficiencies that dissatisfied the military. In June 1975, when the State Council and the Central Military Commission approved the J-7I’s design finalization, they pointed out that the aircraft still did not solve problems inherent in the original Soviet MiG-21 design, such as the unreliable ejection system and its short range. They instructed the Third, Fourth, and Fifth Machine-Building Ministries to accelerate work on four modifications: the installation of a rocket ejection seat, the adoption of the WP-7B engine, the addition of 720-liter auxiliary fuel tanks, and a drag chute.

To enhance the J-7’s tactical and technical performance, Chengdu Aircraft Corporation began improving the J-7I in July 1975 to address the unresolved issues from the earlier design finalization process. This modified version was initially called the “J-7I Modified” but was later formally designated as the J-7II and renamed the J-7B by the air force. In May 1977, the State Council and the Central Military Commission’s Conventional Equipment Development Leadership Group approved the improvement plan submitted by Chengdu Aircraft Corporation, allowing the four modifications to proceed. They demanded that the new aircraft be developed, finalized, and produced for military deployment as quickly as possible.

The J-7II inherited and built upon the “six modifications” scheme of the J-7I but primarily focused on solving the unreliable and unsafe ejection system. The original J-7 prototype and J-7I models used a “canopy-separating ejection system” from the MiG-21F-13. This system aimed to shield the pilot from high-speed airflow during ejection by having the canopy attach to the ejection seat. However, this system was overly complex, leading to unreliability and frequent failures. Its poor performance in low-altitude ejections, combined with the taller sitting height of Chinese pilots compared to their Soviet counterparts, often resulted in head injuries or fatalities when the pilot’s head collided with the canopy. This led to the system being nicknamed the “coffin” by pilots, as it significantly impacted morale and operational readiness.

In March 1975, Chengdu Aircraft Corporation completed the feasibility study for a new rocket ejection system and canopy. In May 1977, the new system was officially approved. The modified system replaced the canopy-separating ejection system with an open ejection system, ejecting the pilot only after the canopy was jettisoned. The canopy near the pilot’s head was raised by 50 mm, and the rescue parachute’s thickness under the seat was reduced to better accommodate Chinese pilots. The canopy opening mechanism was also redesigned, separating the windscreen and the canopy. The windscreen was fixed to the airframe, while the canopy opened upward and backward.

To improve reliability, Chengdu adapted the J-6 rocket ejection system by adding a 2,500-kg-thrust rocket under the seat, which worked alongside a three-stage ejector to form the propulsion system. This reduced the ejection’s g-force impact from 20g to 17g and increased the ejection height from 30 meters to approximately 120 meters. New dual-stage stabilizing parachutes ensured safe deceleration at various speeds, and a central ejection pull ring was introduced to allow a single motion to jettison the canopy, initiate ejection, and separate the seat. The minimum safe parachute deployment height was reduced from 100 meters to 60 meters, improving survival chances. A new survival kit containing 13 items enhanced post-ejection survival, including at-sea rescue and communication capabilities. The system achieved reliable ejections from ground level to high altitudes and speeds of 250–850 km/h, overcoming the J-7 prototype and J-7I’s poor ejection success rates.

The new system underwent extensive ground and flight testing, including over 300 individual tests, 26 rocket sled ejection tests, and 6 dummy ejection trials using a Hong-5 test platform. By August 31, 1979, the ejection system, named the HTY-2 rocket seat, was finalized. It gained widespread military acceptance after proving successful in five emergency ejections between 1984 and 1985, earning the National Quality Gold Award in 1985.

Another major improvement was the installation of the WP-7B (Batch 02) engine, developed by Guizhou Aviation Engine Manufacturing Factory as an upgraded version of the WP-7. The WP-7B featured a redesigned afterburner section, high-temperature turbines, and hollow turbine blades, increasing maximum thrust from 3,900 kg to 4,300 kg, and afterburner thrust from 5,750 kg to 6,100 kg, while reducing fuel consumption by 2%. However, the higher exhaust and wall temperatures created significant heating issues for the aircraft’s rear fuselage and components. Heat insulation and cooling measures, such as modifying structural materials, using double-layer hollow structures, and adding heat shields, were implemented. Despite these measures, the high-temperature issues persisted during initial military use and required additional modifications by Chengdu Aircraft Corporation in 1992 to fully resolve.

The J-7II also featured an upgraded fuselage auxiliary fuel tank, increasing its capacity from 480 liters to 720 liters, enhancing its combat radius and endurance. The aircraft retained the drag chute relocation from the J-7I later models, mounted at the base of the vertical tail to shorten landing rollout distances and extend nose wheel lifespan.

The first J-7II prototype successfully flew on December 30, 1978, piloted by Yu Mingwen. Between March and June 1979, two prototypes underwent test flights, completing 94 sorties and 59 hours of flight. The National Aircraft Design Finalization Committee approved the design on September 26, 1979. By December 1980, after five production batches (40 aircraft), the J-7II transitioned into mass production. Production at Chengdu Aircraft Corporation and later at Guizhou (011 Base) ensured stable quality and rapid delivery to military units. Between 1979 and 1986, a total of 375 J-7IIs were produced, with Guizhou manufacturing around 100 of these units. The J-7II was well-received by the military for its improved performance as a daytime light fighter. It became the baseline for subsequent J-7 variants and earned the First Prize in National Defense Industry Technology Improvements in 1980.

In the October 1, 1984, National Day parade commemorating the 35th anniversary of the People’s Republic of China, 35 J-7II aircraft flew in formation over Tiananmen Square.

J-7II Towing Target Aircraft

Spoiler

The J-7II towing target aircraft is a modified version of the J-7II, equipped with a target towing mechanism mounted on the auxiliary fuel tank pylon under its fuselage. This modification enables it to tow the Air Target-4 aerial target for live-fire training exercises. The target is towed by the J-7II in flight to simulate an aerial target, allowing fighter aircraft or ground-based anti-aircraft guns to conduct live-fire training.

J-7II Export

Spoiler

After Egypt received the first batch of 20 J-7A aircraft, it raised concerns about the aircraft’s shortcomings in May 1981. Egypt requested improvements for the remaining 40 J-7A aircraft yet to be delivered, focusing on the ability to mount 720-liter auxiliary fuselage fuel tanks and enhancements to the ejection system. Compared to the J-7A, the export version featured an open ejection system, replacing the original configuration. It also upgraded to the WP-7B engine with a first overhaul interval extended to 200 hours, a performance-enhanced 222 radar rangefinder, and pre-installed cables in the wings to later adapt the French R550 “Magic” short-range air-to-air missile. Additionally, the fuselage auxiliary fuel tank capacity was increased to 720 liters. The technical configuration of this improved aircraft was essentially equivalent to the J-7II model that Chengdu Aircraft Corporation was producing at the time. To avoid confusion during production and technical handover, this aircraft was internally referred to as the “J-7II Export Variant.”

By late 1982, all 40 J-7II Export Variant aircraft ordered by Egypt were assembled and delivered to the Egyptian Air Force. In total, the export of 60 aircraft (including the earlier batch of 20) generated approximately $200 million in foreign exchange revenue for China. Additionally, 15 units of the J-7II Export Variant were sold to the United States to be used by adversary squadrons for training purposes, simulating MiG-21 aircraft. China also provided four units of this model to Zimbabwe as military aid.

J-7IIA

Spoiler

The J-7IIA, while building on the improvements made in the J-7II, revealed that the upgrades primarily addressed usability and reliability issues of the original MiG-21F-13 design, without significantly improving the aircraft’s overall performance. The J-7II still resembled early MiG-21 variants in terms of capability, reaching only the technological level of 1950s fighter aircraft. In contrast, by the 1970s, third-generation fighters from the West, such as those produced by the United States, were entering service and demonstrating full combat capability. The Soviet Union’s formidable fleet of advanced fighters posed an increasing and urgent threat to China’s national security.

During this period, China also began its policy of reform and opening up to the world, exposing its aviation and defense leaders to the harsh reality that the technological level of Chinese fighter jets lagged significantly behind foreign aircraft. This gap was particularly pronounced in avionics such as radar and other electronic systems, making it difficult to effectively secure Chinese airspace.

In June 1978, Deng Xiaoping, while overseeing the Central Military Commission, emphasized the need to raise domestic aircraft technology levels by importing advanced foreign technologies, studying them thoroughly, and independently developing them further. With China and the West aligning over shared concerns about Soviet expansion, Sino-Western relations began to thaw during the latter part of the Cultural Revolution. Following U.S. President Richard Nixon’s visit to China in 1972, diplomatic ties between China and Western nations reached their best state since the founding of the People’s Republic. This environment made the possibility of importing advanced Western aviation technology feasible.

From November 2 to December 23, 1978, a Chinese aviation delegation led by Minister Lü Dong of the Third Ministry of Machine-Building, along with Vice Ministers Duan Zijun, Chen Shaozhong, and Xu Changyu, visited the United Kingdom, France, and West Germany for 52 days to collect firsthand information about Western aviation industries. During this time, the UK and France expressed interest in selling their Harrier and Mirage fighter jets to China. While acquiring advanced Western fighters could rapidly reduce China’s technology gap, their high cost rendered them unaffordable. Consequently, a committee comprising the General Staff Department, the National Defense Industry Office, the Third and Fourth Ministries of Machine-Building, and representatives from the air force and navy decided to begin by importing radar and electronic fire-control systems to upgrade the J-7 and J-8 fighters. This strategy aimed to address the weakest areas in Chinese fighters while providing a means to quickly enhance China’s outdated avionics capabilities.

On March 3, 1979, with support from the China National Aero-Technology Import & Export Corporation (CATIC), Chengdu Aircraft Corporation began negotiations with the UK’s Marconi Company on the import of six types of aviation electronics. After 16 months and ten rounds of arduous negotiations, a contract for jointly upgrading J-7 fighters was signed on June 30, 1980. This marked China’s first military technology collaboration with the West since the beginning of reform and opening up. In addition to sourcing six types of equipment from Marconi, China also signed a separate contract with Smiths Industries to import radio altimeters. Together, these contracts covered seven types of electronic equipment, totaling 124 sets, intended for retrofitting 100 J-7 aircraft (including spare parts). Licenses for domestic production of these items were also secured. The imported electronics included the “Skyranger” 7M radar rangefinder, 50-408-02 atmospheric data computer, AD3400 multi-band communication radio (with an AA3460 encryption module), 956 head-up display (HUD), 2032 gun camera, DH-1030-24-1200-CS-IIB static inverter (two single-phase and one three-phase), and the 0101-HRA/2 radar altimeter. Notably, the static inverter was acquired from the U.S. company Phoenix through Marconi to replace the original rotary converter, ensuring a stable power supply for the imported systems.

On September 31, 1980, the Chinese government approved the contract. The Third Ministry of Machine-Building assigned production of the radar rangefinder to Lanzhou Changfeng Machinery Factory (Factory 781), the atmospheric data computer to Chengdu Aerospace Instrument Factory (Factory 161), the communication radio to Tianjin Radio Factory (Factory 712), the radar altimeter to Baoji Changling Machinery Factory (Factory 782), the static inverter to Xingping Qinling Aerospace Electric Factory (Factory 135), and the gun camera and HUD optical components to Xi’an Northwest Optical Instrument Factory (Factory 248), with Suzhou Changfeng Machinery Factory (Factory 171) responsible for HUD assembly.

By September 1980, Chengdu Aircraft Corporation completed the overall design for incorporating these advanced electronic systems into the J-7. The improved aircraft was designated the J-7IIA. In November 1980, the Third Ministry of Machine-Building formally approved the modification project. To support the imported systems, the J-7IIA also included seven new domestically developed systems, such as the LZ-2 integrated compass, XS-6A beacon receiver, GGJ-7 pitot tube, GGJ-9 angle-of-attack sensor, CW-1002 total air temperature sensor, BM2.5 Mach meter, and WL-7 radio compass control box with copper mesh antenna. As a result, existing systems like the Shemiao-3A gunsight, 226 radar rangefinder, CT-3 UHF radio, 262 radar altimeter, and Xiangong-4A gun camera were removed.

The aircraft’s structure underwent modifications to accommodate the new systems. The radar radome was redesigned to meet the electrical requirements of the British radar rangefinder. The top of the vertical tail was fitted with a new fiberglass fairing to house the VHF radio antenna. Additionally, the folding pitot tube under the nose was replaced with a fixed unit, mounted above and to the right of the nose for easier maintenance.

The J-7IIA aimed to improve the Chinese Air Force’s J-7II fleet with advanced foreign avionics, intending to install imported equipment in the first 100 aircraft, with domestically produced substitutes planned for later. However, shortly after signing the contract with the UK, financial constraints led to a reassessment of import plans. Faced with dwindling foreign exchange reserves and reduced military budgets, the air force canceled its request for the upgraded aircraft in February 1981 and withdrew from the British equipment project. Since canceling the contract would have incurred significant penalties and forfeited an opportunity to enhance the J-7’s combat capabilities, the project was repurposed for export. In June 1981, Jordan placed an order for 80 upgraded J-7 fighters with advanced avionics, prompting the continuation of the project as an export model.

Three aircraft were designated for testing: two J-7IIA prototypes equipped with imported systems and one J-7 from factory reserves fitted with domestic systems. In September 1982, test flights began under the direction of the project’s chief designer, Tu Jida. After resolving various technical issues, including radar interference and HUD stability, the J-7IIA completed a year-long series of tests, culminating in its successful evaluation in March 1984.

J-7B

Spoiler

After the successful development and production of the J-7II, Chengdu Aircraft Corporation continued improving the aircraft for export based on various customer requirements. The first such variant was the J-7B, designated as the F-7B for export. On June 27, 1981, CATIC (China National Aero-Technology Import & Export Corporation) signed a contract with the Kingdom of Jordan for the purchase of 80 upgraded J-7II aircraft, with a total value exceeding $200 million. Due to the complexity of Jordan’s requested upgrades and the extended modification timeline, the delivery schedule could not meet Jordan’s expectations. Therefore, during contract negotiations, both parties agreed to deliver the first batch of 20 aircraft with relatively simple modifications by late 1982, while the remaining 60 aircraft would be delivered after completing the full set of upgrades. This approach met Jordan’s urgent needs while allowing time for domestic development progress. The first batch of 20 modified J-7II aircraft was designated as the J-7B.

The J-7B was developed based on Jordan’s requirements, which included equipping the aircraft with infrared air combat missiles, improving the ejection system’s safety, and extending the lifespan of onboard equipment and components. To achieve these goals, the structure and circuits of the wing pylons were redesigned to coordinate mechanical and electrical interfaces and equipment compatibility. This allowed the pylons to mount and fire both the French R550 “Magic” infrared-guided air-to-air missile and the Chinese PL-2 infrared-guided air-to-air missile.

The J-7B’s propulsion system was upgraded with the WP-7B (M Batch) engine featuring kerosene starting and extended lifespan. This engine was an improvement developed by Guizhou Liyang Engine Manufacturing Factory in 1979 as an upgrade to the WP-7B. The modifications increased overhaul intervals from 100 hours to 200 hours and extended the total service life to 600 hours, double the original WP-7B engine’s lifespan, while significantly improving reliability. The kerosene starting system eliminated the need for gasoline, simplifying maintenance and preparation procedures by drawing fuel directly from the aircraft’s tanks. It also avoided the vapor lock issues associated with gasoline at high altitudes, improving mid-air restart reliability. Additionally, a linked ignition system was introduced to prevent mid-air engine shutdown due to smoke inhalation during missile firing, ensuring continuous engine operation.

Jordan required the ejection system to provide safe ejection under zero altitude and zero speed conditions, which exceeded the capabilities of the J-7II’s system. After negotiations, an agreement was reached to deliver aircraft meeting the Soviet MiG-21’s ejection specifications, expanding the original ejection envelope from “zero altitude, airspeed 250–850 km/h” to “zero altitude, airspeed 130–850 km/h.” To verify this capability, the modified rocket ejection seat underwent three ground tests on a Hong-5 test aircraft at low-speed taxiing conditions. The results confirmed that the expanded ejection envelope was feasible, further enhancing the aircraft’s competitiveness in the export market.

Additional improvements in the J-7B included new onboard equipment, such as the 222 radar rangefinder, 602 friend-or-foe identification system, LS-16C main landing wheel, Hangjia 11-10 gun camera, and DH-1030-24-1200-CS-IIB static inverter (imported from Phoenix, USA). Since Jordan requested defined service lifespans for onboard equipment—a task previously unaddressed in China—domestic manufacturers completed extensive testing and provided lifespan specifications for all onboard systems. These lifespans were generally extended compared to the J-7II, reaching approximately 60% of the service life of Soviet equivalent systems.

In July 1981, the Third Ministry of Machine-Building officially issued the modification task for the J-7B aircraft, designating the export of 80 aircraft to Jordan as a priority project during the “Sixth Five-Year Plan” period. In June 1981, Chengdu Aircraft Corporation completed the overall development plan for the J-7B aircraft, which was approved in November of that year, marking the start of official development. Peng Renying served as the chief designer for the J-7B. The aircraft’s maiden flight took place on May 16, 1982, piloted by Liu Jianzhong, and by November 1982, all 20 J-7B aircraft were assembled and delivered to Jordan. These aircraft were later transferred to Iraq.

J-7M

Spoiler

The J-7M was developed as the second batch of 60 aircraft specified in Jordan’s purchase agreement. This model incorporated the improvements made in the J-7IIA and J-7B while integrating additional requirements from Jordan. Exported under the designation F-7M, the “M” in its name represented “export model,” and the aircraft earned the nickname “Air Guard” from foreign aviation media. Based on the J-7IIA configuration, the J-7M was equipped with seven electronic systems imported from the UK, collectively referred to as the MADS-7 (Marconi Aircraft Defense System). These included the “Skyranger” 7M radar rangefinder, 50-408-02 atmospheric data computer, AD3400 multi-band communication radio, 956 head-up display (HUD), 2032 gun camera, DH-1030-24-1200-CS-IIB static inverter, and 0101-HRA/2 radio altimeter. Unlike the J-7IIA, the multi-band communication radio lacked an encryption module, no VHF antenna was installed at the top of the vertical tail, and the pitot tube was fixed in the upper-right position on the nose.

Other onboard systems underwent lifespan extension, reaching 75% of the service life of similar Soviet-made equipment. Of the 373 onboard components, 86 were newly selected (35 imported and 51 domestically produced). Additionally, the poor optical quality of domestically manufactured windscreen glass affected HUD alignment accuracy, prompting the import of high-quality bird-strike-resistant glass from Britain’s Triplex Company.

The J-7M included a pair of outer wing pylons, capable of mounting 480-liter auxiliary fuel tanks. Combined with the fuselage pylons, this allowed three auxiliary fuel tanks to be carried simultaneously, significantly increasing the aircraft’s combat radius. The fuel system was also modified accordingly. Alternatively, the outer pylons could mount rocket launchers or bombs, adding flexibility to the weapon configuration. The total number of hardpoints increased to five, enhancing weapon carrying capabilities. The inner pylons retained the J-7B configuration, supporting both PL-2 air-to-air missiles and the French R550 “Magic” missiles, or alternatively rocket launchers and bombs.

The increased weight of wing-mounted equipment necessitated structural reinforcement for the wings. To ensure design continuity and reduce development time, 75% of the wing components were identical to those of the J-7II. Modifications also extended to the landing gear, with the forward gear adopting the design used in the J-7III, which was under development at the time. The main gear received strengthened struts and tubeless wheels.

The powerplant was upgraded to the WP-7B (BM Batch) engine, an improved version of the WP-7B (M Batch) engine used in the J-7B. Weight-reduction measures were implemented, increasing maximum thrust to 4,320 kg and afterburner thrust to 6,100 kg. Like the J-7B, the rocket ejection seat allowed safe ejection under zero altitude and airspeeds of 130–850 km/h.

Weight-reduction measures on the airframe, along with lighter imported equipment and wing-mounted auxiliary fuel tanks, shifted the center of gravity rearward compared to the J-7II. To restore balance, 130 kg of ballast was added to the aircraft’s nose.

Development of the J-7M officially began in September 1981, with Peng Renying serving as the chief designer. The project progressed simultaneously with the J-7IIA and J-7B. During development, over 2,000 wind tunnel tests, structural tests for wing pylons and landing gear, fuel system simulations, electrical principle tests, power equipment load tests, radar radome and antenna performance tests, linked ignition system tests, and engine smoke-ingestion tests were conducted. These trials validated the feasibility of the modifications and contributed to subsequent export variants.

Two J-7M prototypes were completed in August 1983. As the British electronic systems had not yet arrived, these aircraft were initially flown without the imported equipment. The first flight took place on August 30, 1983, piloted by Yu Mingwen. Following initial trials of flight performance and control characteristics, the imported systems were retrofitted, and comprehensive validation flights were carried out. To expedite testing, additional aircraft were utilized: two J-7Bs for missile compatibility and engine-linked ignition system tests, two J-7IIAs for testing British equipment, and two J-7IIs for fuel system and external payload trials. A total of eight aircraft participated in testing, completing nearly 500 flights.

To meet Jordan’s urgent delivery requirements, production began in October 1983 before the imported systems were fully delivered. The first batch of ten production aircraft was assembled. By March 1984, the first set of British electronic systems arrived from Marconi, and by April, the first J-7M in full technical configuration was completed. The first batch of aircraft underwent factory test flights and was delivered to Jordan in July 1984. By the end of 1984, 30 aircraft were delivered, and the remaining 30 were completed by May 1985. Later, Jordan transferred these J-7Ms to Iraq. Apart from exports to Jordan, one J-7M was sold to the United States.

Through the integration of advanced foreign avionics, the J-7M gained capabilities such as HUDs, high-accuracy rapid targeting, long-range radar detection, strong anti-jamming capabilities, advanced communication systems, and extended lifespan for its engine and onboard equipment. These enhancements significantly improved combat performance and export competitiveness. Overall, the J-7M represented a notable advancement over the J-7II, becoming China’s most advanced light fighter at the time and serving as the foundation for subsequent J-7 export variants. In 1985, the J-7M received the National Science and Technology Progress First-Class Award, followed by the National Quality Gold Medal in 1988—China’s first gold award for large, complex weaponry. The J-7M series achieved significant export success, with nearly 200 units sold to Jordan, Pakistan, Bangladesh, Iran, Zimbabwe, and other countries.

J-7IIH

Spoiler

After the Chinese Air Force abandoned plans to upgrade its J-7II fleet with British electronic systems, improving the combat capabilities of the J-7 became an urgent issue. During this time, Israeli involvement in the J-7 upgrade program introduced a cost-effective solution to enhance the aircraft’s attack capabilities.

In the early 1980s, large-scale air battles erupted between Israel and Syria over Lebanon’s Bekaa Valley. The exceptional performance of the Israeli Air Force during these battles shocked the world, leaving a strong impression on the Chinese Air Force, especially regarding the advanced infrared-guided “Python” air-to-air missiles used by Israeli fighter jets. Recognizing the importance of air-to-air missiles in future combat, the Chinese Air Force grew increasingly interested in such systems. Meanwhile, Israel sought closer relations with China in hopes of reducing Chinese weapons exports to Middle Eastern Arab nations, particularly the sale of long-range tactical surface-to-surface missiles.

From 1982, China and Israel began secret negotiations to import Python-3 missiles. Chengdu Aircraft Corporation’s engineers, with support from Israeli Rafael specialists, worked on integrating the Python-3 missile onto the J-7II aircraft. However, due to international diplomatic constraints—China had no official relations with Israel and sought to maintain friendly ties with other Middle Eastern countries—the collaboration remained unofficial and informal. Chinese engineers could not visit Israel, and Israeli experts only engaged with China under private identities as lecturers or tourists. Despite these limitations, the cooperation progressed smoothly, culminating in an agreement for production licensing and the acquisition of complete manufacturing technologies for the Python-3. This missile, known domestically as the PL-8, became China’s first highly maneuverable short-range infrared-guided air-to-air missile. The PL-8 utilized a nitrogen-cooled indium-antimonide infrared seeker, supporting large off-boresight angles and omnidirectional attack capability, with enhanced maneuverability. Its overall performance surpassed that of the U.S.-made AIM-9L and filled a critical gap in China’s arsenal of advanced air combat missiles.

On August 2, 1983, the Commission of National Defense Science, Technology, and Industry formally tasked Chengdu Aircraft Corporation with modifying the J-7II to carry the PL-8 missile. Chief designers Lu Yuying and Song Kaiji completed the integration design in March 1984. Over the next year, a prototype was modified and successfully test-flown in March 1985. On September 9, 1985, the Ministry of Aviation Industry and the Air Force approved the integration of the PL-8 missile, officially naming the upgraded aircraft the J-7IIH, which was later re-designated as the J-7H. The J-7IIH entered service in February 1986, and production continued until its discontinuation in 1993, with a total of 221 units delivered.

To integrate the PL-8 missile, the J-7IIH’s wing pylons were upgraded with GJ3-D universal weapon racks. The missile launch circuits were modified to accommodate the PL-2, PL-5B, and PL-8 air-to-air missiles. The aircraft also received the WP-7B engine with kerosene ignition and extended lifespan, improving operational reliability and maintenance. The wing structure and main landing gear struts were reinforced to handle the increased weight, and LS-16E tubeless main wheels were installed. For enhanced battlefield survivability, the J-7IIH was equipped with the 941-4C integrated chaff/infrared flare dispenser, marking the first deployment of electronic self-defense systems on a J-7 aircraft.

The PL-8 missile weighed 120 kg, a 60% increase over the PL-2’s 75 kg, significantly shifting the aircraft’s center of gravity rearward and adversely affecting flight stability. Initial attempts to balance this by redistributing fuel within internal tanks proved insufficient due to the limited fuel capacity of the J-7. As a result, additional ballast was installed in the forward fuselage to maintain flight stability comparable to the J-7II. However, the increased weight from the missile and ballast reduced the aircraft’s maneuverability. Since infrared-guided missiles like the PL-8 relied on positioning via maneuvering to engage targets in their rear hemisphere—where hit rates were highest—the decline in agility negatively impacted the missile’s effectiveness.

J-7HH

Spoiler

The J-7HH is the naval variant of the J-7IIH aircraft, designed to meet the operational requirements of the naval aviation forces. Its configuration is largely identical to the J-7IIH used by the air force. However, due to the corrosive effects of high-salinity seawater and humid air on aluminum alloy structures, the J-7HH incorporates additional protective measures against moisture, salt spray, and mold. To further enhance durability in marine environments, all magnesium alloy components in the aircraft were replaced with aluminum alloy materials.

J-7IIK

Spoiler

The J-7IIK is a military aid aircraft developed based on the J-7IIH at the request of the air force, designated for export as the F-7BK. In response to Myanmar’s request, China decided to assist by providing a batch of J-7 aircraft to enhance the operational capabilities of its air force. The J-7IIK adopted the wings of the J-7M, which included an additional pair of outer wing pylons. These were equipped with improved universal weapon racks capable of carrying auxiliary fuel tanks, rocket launchers, or bombs. The fuel system was also derived from the J-7M to accommodate the use of auxiliary fuel tanks.

The aircraft was powered by the WP-7C engine, an extended-life and further improved version of the WP-7B engine, offering increased maximum thrust and reliability. To reduce costs, the J-7IIK omitted the foreign avionics imported for the J-7M. Instead, it featured a limited number of upgraded systems based on the J-7IIH, including the SRT-651C communication radio, 602 friend-or-foe identification system, GG-15 altitude signaler, and XJ-6 overload sensor. Additionally, the cockpit instrument panel was modified to align with foreign pilots’ operating habits, and other cockpit systems were adjusted to accommodate the updated onboard equipment.

In 1990, Chengdu Aircraft Industry Company delivered the first batch of 10 J-7IIK aircraft to the military. By 1999, a total of 58 units had been delivered.

J-7BS

Spoiler

The J-7BS is an export variant of the J-7IIK, further simplified to meet Sri Lanka’s cost-control requirements. It was designated as the F-7BS for export, with the “S” in the designation representing Sri Lanka. To reduce expenses, the J-7BS omitted certain expensive onboard electronic systems and simplified related functionalities. It was equipped with the WP-7B (BM Batch) IV engine.

The first flight of the J-7BS took place on September 13, 1991. In October of the same year, the aircraft was delivered to Sri Lanka. The Sri Lankan Air Force purchased a total of four J-7BS aircraft, with the serial numbers CF704, CF705, CF707, and CF708. These aircraft were stationed at Katunayake Air Force Base.

J-7IIM

Spoiler

The J-7IIM is a domestic variant of the J-7M designed for use by the Chinese Air Force. Due to the advanced fire-control systems and weapon mounting capabilities of the J-7M compared to the J-7II, the Chinese Air Force sought to equip the J-7M with PL-8 missiles to further enhance its overall combat performance. By the 1980s, China’s rapid economic growth, expanding foreign trade, and increasing GDP and foreign exchange revenues provided the air force with the funds to acquire a limited number of these advanced fighters.

The J-7IIM was developed on the basis of the J-7M but replaced the inner wing pylons with those of the J-7H, improving the GJ3-D universal weapon rack to support PL-2, PL-5B, PL-7 (the domestic version of the French R550 “Magic”), and PL-8 air-to-air missiles. Additionally, it included weight adjustments at the front fuselage as seen in the J-7IIH configuration, which slightly reduced its flight performance compared to the J-7M. The 956 head-up display (HUD) was upgraded to include ballistic parameters and missile tail-chase attack zone indicators for PL-8 missile deployment. The YD-3 friend-or-foe identification system from the J-7II was retained to align with domestic command environments. The engine was upgraded to an improved version of the WP-7B engine featuring dual-channel ignition and measures to prevent nozzle automatic expansion. The ejection system maintained the rescue range specifications of the J-7II: zero altitude to ceiling and airspeed of 250–850 km/h.

In 1986, the first batch of J-7IIM aircraft capable of deploying PL-8 missiles was delivered to the Chinese Air Force. With substantially higher combat efficiency compared to the earlier J-7H, the J-7IIM became the most capable variant of the J-7 equipped by the air force prior to the 1990s.

J-7IIN

Spoiler

The J-7IIN is an export variant of the J-7II, specifically modified for Zimbabwe, and is designated as the F-7BN for export. It features the wings, underwing pylons, landing gear, engine, and fuel system from the J-7M. The weapon and auxiliary fuel tank configurations are also identical to those of the J-7M. To reduce costs, the J-7IIN primarily uses domestically produced Chinese avionics. However, like the J-7B, it replaces the DBL-500A rotary converter used in the J-7II with the DH-1030-24-1200-CS-IIB static inverter imported from the U.S. Phoenix Company, ensuring sufficient power for launching French R550 “Magic” air-to-air missiles.

As Zimbabwe is located in a tropical region with consistently high temperatures, the J-7IIN was equipped with improved cockpit air conditioning for better cooling efficiency. Additionally, the alcohol-based windshield de-icing system, intended for cold regions, was removed. The aircraft also omitted the battery heating and helmet heating systems, as well as the friend-or-foe identification system.

In 1987, Chengdu Aircraft Industry Corporation delivered eight J-7IIN aircraft to the Zimbabwe Air Force. These aircraft were integrated with four previously supplied J-7II export variants to form the 5th Fighter Squadron. Apart from interception missions, the squadron also carried out ground attack operations.

J-7MP

Spoiler

The development of the J-7 sparked interest from China’s neighboring country, Pakistan. As early as 1983, during the radar precision test flights of the J-7IIA in Dalian, Pakistan’s Air Force Vice Chief of Staff, Lt. Gen. Jamal, and his delegation visited Dalian to inspect the aircraft. After the inspection, the Pakistani side expressed interest in purchasing the aircraft, as the onboard systems, such as the head-up display (HUD), met the needs of the Pakistan Air Force (PAF). They decided to send two pilots to test-fly the aircraft to determine its suitability as a replacement for their retiring J-6 fighters.

In December 1983, two Pakistani pilots arrived at the Xi’an Yanliang Flight Test Research Institute to conduct test flights on the J-7IIA. After 19 flights, they found the aircraft’s performance satisfactory but suggested improvements. To further assess the aircraft, Pakistan requested live-fire tests, requiring the aircraft to validate its fire-control system through live missile and cannon tests. In response, China sent one J-7IIA and one J-7M to Pakistan’s Peshawar Airport on June 9, 1984. Over two months, Pakistani pilots conducted 40 flights, testing the aircraft in air-to-air gun combat, air-to-ground gun strafing, rocket launches, and bombing exercises. Simulated combat flights were conducted against J-6, Q-5, Mirage-5, and F-16 aircraft. These tests proved the improved fire-control systems of the J-7 to be highly accurate—twice as precise as the original optical gunsight. Pakistan deemed the aircraft’s modifications successful and expressed an intent to purchase 55 J-7M aircraft.

Following the live-fire tests, Pakistan Air Force representatives began negotiations with CATIC (China National Aero-Technology Import & Export Corporation) and Chengdu Aircraft Corporation for purchasing J-7M aircraft. Due to Pakistan’s extensive requests for additional modifications, the negotiations were protracted, and the first order of 20 aircraft was finalized only in 1985. The technical specifications for the delivered aircraft were revised through eight rounds of discussions, with final agreement reached in November 1987.

The J-7M modified to meet Pakistan’s requirements was designated the J-7MP, or F-7P for export, with “P” denoting Pakistan. The J-7MP incorporated 24 modifications compared to the J-7M. Its avionics were significantly upgraded, including American Collins AN/ARC-164 and AN/ARC-186 radios, an APX-101 friend-or-foe identification system, and an LJ-2 omnidirectional radar warning receiver.

To accommodate the physical stature of Pakistani pilots, the control stick was shortened by 50 mm to reduce arm fatigue and improve ergonomics. Rearview mirrors were added to enhance situational awareness. Additional cockpit features included a backup magnetic compass, central warning light, and controls for the LJ-2 radar warning system. The layout of the cockpit was reorganized and optimized for easier access and operation, aligning with Pakistani pilots’ preferences. The ejection seat was replaced with the British Martin-Baker MK.10 zero-zero ejection seat, which provided superior performance compared to the seat used in the J-7M. As the PAF used Western-style pilot helmets, the original oxygen system was replaced with a Western-compatible oxygen disconnect system, ensuring safe oxygen supply up to 12,000 meters.

The J-7MP’s weapon systems also saw significant upgrades. Outer wing pylons, which on the F-7M could only carry auxiliary fuel tanks, rocket launchers, or bombs, were modified to also support air-to-air missiles. The new universal weapon rack included bolt holes for missile launchers, interchangeable hooks for rocket pods, and dual hooks for various bombs. The inner wing pylons supported PL-5B, PL-7, R550 “Magic,” AIM-9P “Sidewinder” air-to-air missiles, LAP-68 rocket launchers, and MK.82, MK.20, and MK.117 bomb series. The outer pylons could carry PL-5B and AIM-9P missiles, LAP-68 rocket launchers, MK.82 and MK.20 bombs, or 480-liter auxiliary fuel tanks. The fuselage pylon supported a 720-liter auxiliary tank. These improvements provided a more versatile payload configuration, increasing the maximum takeoff weight and low-altitude top speed compared to the J-7M. The 956 HUD software was updated to include trajectory parameters and status indicators for these weapons.

Maintenance was also improved, with many removable access panels replaced with quick-release fasteners instead of screws, as requested by Pakistan. This made it easier for ground crews to access internal components for servicing, enhancing the aircraft’s overall maintainability.

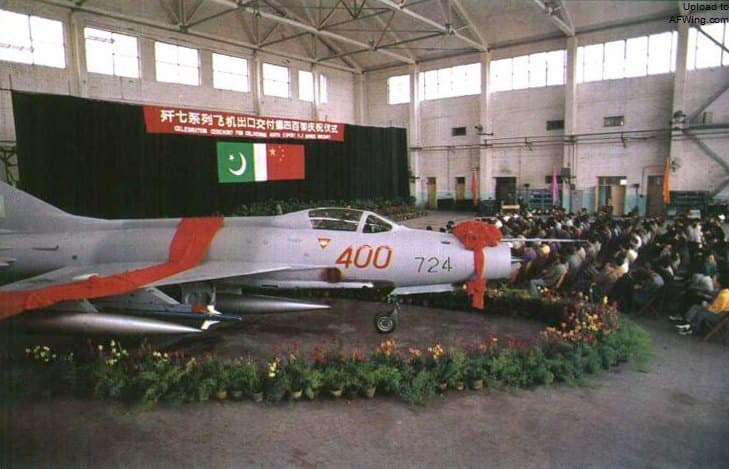

The chief designers of the J-7MP were Lu Yuying and Peng Renying. On June 9, 1988, test pilot Lu Guotang conducted the maiden flight of the J-7MP, which soon passed technical appraisal by the Ministry of Aviation Industry. On July 26, 1988, China and Pakistan held a handover ceremony, and the first batch of 20 J-7MP aircraft was delivered to the Pakistan Air Force from Hotan Airport in Xinjiang.

J-7P

Spoiler

The J-7P is a further upgraded version of the J-7MP. After receiving the first batch of 20 J-7MP aircraft, Pakistan expressed satisfaction with their performance and decided to purchase an additional 40 units by the end of 1987, while also requesting several enhancements. The second batch of J-7P aircraft was equipped with the Chinese-made HTY-4 rocket ejection seat, capable of safe ejection at zero altitude and airspeeds exceeding 140 km/h. The HTY-4 seat, developed from the HTY-3, was used not only in the J-7P but also in China’s J-8 fighter. It offered effective pilot-seat separation and could deploy a stabilizing parachute early, rapidly opening the main parachute to reduce deployment time.

The cockpit layout and navigation avionics were further refined, with more integrated control units. Notably, the cockpit layout differed slightly between the first 20 and the remaining 40 aircraft. The HUD (head-up display) underwent changes to meet Pakistan’s requirements, with all metric units replaced by imperial units for display. Additional functionalities included gun-priority selection and firing start/stop indicators to align with Pakistani pilots’ preferences. A new radar warning receiver (RWR) system was installed to replace the J-7MP’s LJ-2 omnidirectional RWR. The cockpit received updated control boxes and indicators for the RWR, and the HUD was integrated with the warning system to provide pilots with timely threat alerts. The environmental control system was upgraded with an improved turbine cooler, and two additional air conditioning vents were added to the cockpit instrument panel for better cooling efficiency. To facilitate aircraft adjustments, a quick adjustment mechanism for the rudder pedals and a trim tab for the rudder were added. Other systems and equipment remained largely consistent with the J-7MP configuration.

The first batch of J-7P aircraft was delivered to the Pakistan Air Force (PAF) in September 1989. In 1993, the PAF selected the Grifo-7 multifunction fire-control radar from Italy’s FIAR company to upgrade the J-7P, replacing the original “Skyranger” 7M radar rangefinder. The Grifo-7 radar, a compact and advanced system, featured pulse compression technology with a detection range of up to 55 km—far surpassing the capabilities of the Skyranger radar. It offered strong electronic countermeasures capabilities, full look-up and look-down search modes in pulse-Doppler and pulse-repetition frequency (PRF) waveforms, and the ability to detect both aerial and ground targets. Relevant data could also be displayed on the HUD, enabling the J-7P to perform all-weather air combat and ground attack missions.

The upgraded J-7P with the Grifo-7 radar first flew in May 1996. Pakistan subsequently ordered an additional 32 units of this improved J-7P model. Additionally, earlier-delivered J-7P aircraft were retrofitted with similar upgrades. Reports also indicate that the first 20 J-7MP aircraft were upgraded to the same radar and avionics configuration as the final batch of J-7P aircraft.

J-7MB

Spoiler

The J-7MB is an upgraded version of the J-7M, modified based on Bangladesh’s requirements and designated for export as the F-7MB, with “B” standing for Bangladesh. To replace its aging fleet of J-6 aircraft, the Bangladesh Air Force showed interest in the J-7M. In April 1989, China and Bangladesh signed a contract for the purchase of 14 J-7MB aircraft, which were delivered in October 1989 via Kunming Airport.

The J-7MB is largely similar to the J-7M but is equipped with the WP-7C engine, offering improved thrust characteristics compared to the WP-7B (BM Batch) engine installed in the J-7M. The inner wing pylons were modified to allow the mounting of PL-7 air-to-air missiles. Both the inner and outer wing pylons could carry rocket launchers, while the underside of the wings could be equipped with smoke dispensers. The fuselage pylon supported auxiliary fuel tanks and the 3A target towing system for aerial gunnery training.

To enhance the aircraft’s self-defense capability, the LJ-2 omnidirectional radar warning receiver was added. The cockpit instrument panel and control console layout were optimized to match the arrangement used in the J-7P aircraft. Additionally, to meet specific operational requirements from Bangladesh, some aircraft were fitted with aviation cameras under the wings for tactical reconnaissance missions.

J-7N

Spoiler

During the Iran-Iraq War, Iran’s Air Force encountered Iraqi Air Force J-7M aircraft in combat, and the impressive performance of the J-7M caught Iran’s attention. This led Iran to initiate contact with China National Aero-Technology Import & Export Corporation (CATIC) to acquire J-7M aircraft. Based on the requirements put forth by the Iranian Air Force, Chengdu Aircraft Industry Corporation developed a modified version of the J-7P, designated the J-7N for domestic use and exported as the F-7N. The “N” in the designation stands for Iran.

The J-7N replaced the original radio compass navigation system with the AD2780 TACAN navigation system, which included air-to-ground functionality, improving close-range navigation accuracy. To align with Iranian pilot preferences, the cockpit’s flight instruments—including the altimeter, speedometer, barometric altimeter, speed/Mach combination indicator, and climb/turn combination indicator—were converted from metric to imperial units. To lower procurement costs, the J-7N retained the oxygen system from the J-7M, instead of adopting the more advanced oxygen system used in the J-7P. Avionics included the AD3400 multi-band communication radio from the J-7M and a domestically produced flight parameter recorder.

The J-7N was equipped with the same WP-7C engine as the J-7MB, which increased maximum thrust. Further refinements were made to the aircraft’s structural systems and maintainability, making it easier to service. Between late 1990 and early 1991, Chengdu Aircraft Industry Corporation delivered two batches totaling 30 J-7N aircraft to the Iranian Air Force.

J-7II HUD Fire-Control System Test Aircraft

Spoiler

Since the 1960s, advanced foreign fighter aircraft began incorporating HUD (Head-Up Display) fire-control systems to replace traditional optical gunsights, significantly improving combat effectiveness. China initiated research on HUD technology in 1975 at the Aeronautical Airborne Fire-Control Research Institute (613 Institute). To support the development of the J-13 fighter at the time, the institute conducted feasibility studies starting in 1977 for the first-generation HUD prototype. This involved preliminary research on its electronic and optical components, followed by the completion of the system’s overall design and prototype production. In June 1982, the HUD fire-control system prototype was installed on a modified J-6A aircraft and underwent test flights, which demonstrated that the prototype’s performance essentially met requirements. Prior to this, in December 1980, the J-8II fire-control system’s feasibility studies compared the domestic HUD with the British-imported 956 HUD and concluded that using the domestic HUD for the J-8II was more reasonable. Building on the prototype, the institute further refined the technology to produce an engineering HUD for the J-8II. In 1985, the first engineering HUD was produced and completed testing, followed by initial test flights on a J-6 aircraft.

In 1986, the Air Force decided to test the HUD fire-control system on the J-7II aircraft to assess its tactical performance and operational value. To this end, a J-7II aircraft was converted into a HUD fire-control system test aircraft. The original Shemiao-7A optical gunsight was removed and replaced with the engineering HUD fire-control system, with associated electrical and other systems modified accordingly. Considering installation constraints, the control box from the original system was removed, and its switches and knobs were relocated to the HUD panel to address cockpit space limitations. To ensure the HUD fire-control system could display necessary atmospheric data without an atmospheric data computer, an auxiliary full-static pressure sensor was added to provide data input to the HUD. By September 1986, the aircraft modifications and ground system testing were completed. Between October and December 1986, the J-7II HUD test aircraft underwent two months of flight trials, testing the system’s functionalities, such as forward tracking and line-of-sight aiming. The system operated stably and met installation requirements.

By the early 1990s, the J-8II fighter was officially equipped with the finalized J8IIHK-13 HUD fire-control system.

(No image available)

J-7IIS Stealth Technology Demonstrator

Spoiler

In the early 1980s, the world’s first stealth fighter, the F-117, began secret deployment within the United States Air Force. To maintain secrecy, the F-117 exclusively conducted nighttime flight training, and it wasn’t publicly revealed by the U.S. Air Force until 1988, alongside the B-2 stealth bomber. The F-117’s exceptional performance during multiple conflicts demonstrated the immense strategic value of stealth technology for future warfare. Advances in aviation technology also made beyond-visual-range combat a reality, where gaining the ability to detect and attack first became critical to victory. To enhance fighter survivability and effectiveness while avoiding early detection in combat, aviation powers globally began investing in low-detectability technologies, particularly radar stealth. The United States emphasized stealth capability as a core requirement for fourth-generation fighters like the F-22, aiming to reduce the chances of detection and gain a tactical edge in air combat. Radar stealth technology primarily focuses on reducing radar cross-section (RCS), and the uniquely designed airframes of stealth aircraft like the F-117, B-2, F-22, and F-23 confirmed that optimizing airframe shape was the most effective way to reduce RCS. However, the cost and complexity of developing new stealth airframes made this approach unattainable for most countries except the U.S.

This presented a challenge for aircraft designers: how to retrofit stealth capabilities onto existing aircraft, achieving some level of stealth without altering the airframe or incurring excessive costs and risks. Since modifying existing airframes for optimal stealth design was impractical, alternative approaches focused on other stealth technologies. A combination of radar-absorbing coatings, impedance-loading techniques, and other methods significantly improved stealth characteristics. For example, modifications to the F-16 by applying radar-absorbing materials yielded positive results, and Russia applied similar coatings to the airframes, canopies, inlets, and turbine blades of its aircraft to reduce their RCS.

During this period, China began stealth technology research, analyzing the unique characteristics of the J-7 and considering economic and technological constraints. Chengdu Aircraft Industry Corporation proposed a stealth retrofit pathway for the J-7. Leveraging theoretical and material research progress from Chinese universities and institutes, they converted a J-7 into a stealth demonstrator to evaluate practical improvements. This project represented a significant step in transitioning China’s stealth technology research from theory to practical application.

The J-7 was designed as a close-range air combat fighter, lacking radar and advanced detection capabilities. The likelihood of detection by enemy radar primarily depended on the aircraft’s forward and rear-facing RCS characteristics. Research and testing indicated that within ±30 degrees of forward and rear views, the J-7 had a combined RCS of approximately 15 square meters. The largest RCS contributors included the radar rangefinder antenna, radome, air intake, and cockpit. To reduce the antenna’s RCS, a forward-slanted flat surface (FSS) panel with an angle greater than 30 degrees was placed in front of the antenna to block its direct line of sight. Metal components associated with the antenna were coated with radar-absorbing materials to further lower RCS. The radome, a significant source of scattering due to cavity effects, was modified with narrowband radomes or bandpass filter radomes to reduce radar reflection outside operational frequencies. For air intakes, RCS reductions were achieved by replacing the lip edge with radar-absorbing composite material and applying absorbing coatings to parts of the duct’s inner surface. The cockpit’s RCS was minimized by coating the canopy with a thin metallic film, addressing impedance mismatches between the glass and surrounding surfaces, reducing forward and rear-facing RCS. Secondary contributors to RCS included the wings, their interactions with the fuselage, the horizontal and vertical stabilizers, and the exhaust nozzle.

The stealth technology demonstrator was developed using Chengdu Aircraft Corporation’s J-7II aircraft, numbered 137. It tested improvements to the radome, air intake, and cockpit stealth features. The radome’s transmission properties, antenna patterns, and RCS were tested, and results aligned with theoretical performance predictions. For the air intake, computational fluid dynamics analyses were conducted to determine airflow characteristics, and structural vibration tests were performed using simulated components coated with radar-absorbing materials. Reliability testing on air intake coatings further validated their effectiveness. The cockpit’s RCS was analyzed by Beihang University, which studied the use of jagged canopy frame edges and radar-absorbing coatings.

The J-7IIS stealth demonstrator underwent cockpit and air intake ground studies and trials, followed by comparative stealth flight tests and RCS measurements at the Chinese Flight Test Research Institute. Results confirmed that the stealth modifications reduced radar detection probability and achieved the original design goals. This demonstrated the feasibility of retrofitting existing aircraft with stealth features without altering the airframe size or performance metrics. However, the level of RCS reduction achieved through retrofitting was limited. Attaining higher radar stealth capabilities would require entirely new airframe designs incorporating stealth considerations in shape, structure, and materials.

J-7III

Spoiler

The MiG-21F-13 originally acquired from the Soviet Union was a daytime fighter, incapable of conducting operations at night or in complex weather conditions. As soon as the J-7 began entering service, the Air Force demanded an all-weather combat-capable variant. To address shortcomings like the J-7’s limited radar-ranging capabilities and weak armament, Chengdu Aircraft Corporation began studying an all-weather version inspired by the MiG-21PF after observing it during a 1972 overseas visit. In May 1975, Chengdu submitted an improvement proposal to the Third Ministry of Machine-Building. By November 1976, the development task was transferred to Base 011 (in Guizhou), following another visit abroad to assess the MiG-21MF.

Collaboration between Base 011 and Chengdu Aircraft Corporation began in 1977, with Chengdu submitting a new design for the J-7 all-weather variant, then designated the “J-7A.” However, progress was slow due to design changes, production priorities, and challenges finalizing the J-7 baseline model. By late 1977, the Central Military Commission accelerated the timeline, demanding a design comparable to the MiG-21MF. It was decided the radar fire-control system should surpass the MiG-21MF in performance, and the aircraft was dubbed the “Major Upgrade J-7.” The Chengdu Aircraft Design Institute (611 Institute) was tasked with leading the overall design, with Wang Shounan as chief designer, later succeeded by Song Wencong.

Design work commenced in July 1978, including on-site visits to friendly nations operating MiG-21MFs, such as Romania and Bangladesh. Through diplomatic means, one MiG-21MF and one MiG-21US from Egypt were acquired to serve as reference aircraft. The modified J-7 was officially designated the J-7III in December 1978, later renamed the J-7C by the Air Force.

The MiG-21MF sample aircraft arrived at Chengdu in February 1979. Lacking a license agreement, the J-7III required reverse engineering from scratch. Although initial debates over whether to replicate or redesign the aircraft caused delays, the urgency of the program ultimately led to reverse engineering based on measurements of the sample aircraft. This approach prioritized speed but limited the ability to fully understand the original design’s rationale. By October 1979, after months of effort, the Chengdu Aircraft Design Institute completed the extensive measurement and mapping of the MiG-21MF.

Major improvements in the J-7III over the J-7II included a significantly larger forward fuselage to house a JL-7 radar with multiple functions such as air-to-air search, automatic tracking, and ground-ranging. The redesigned fuselage improved internal fuel capacity and aerodynamic stability. Additional innovations included larger vertical stabilizers, a new canopy with rearview mirrors, and a side-opening mechanism for ease of access. The lighting system incorporated red illumination for night operations. The emergency ejection system used an improved HTY-3 rocket ejection seat capable of zero-altitude and high-speed ejections. Powered by the domestically developed WP-13 engine, the J-7III’s maximum thrust increased to 6,600 kg with afterburner, while a new fuel system accommodated up to 4,316 liters with auxiliary tanks. Armament upgrades included a twin-barrel 23mm cannon and expanded payload options, including additional hardpoints and compatibility with various air-to-air missiles, rocket launchers, and bombs.

The J-7III faced significant challenges in development, particularly with its reverse-engineered WP-13 engine. Technical issues often delayed flight tests, though persistent efforts eventually met or exceeded the performance objectives comparable to the MiG-21MF. By the early 1980s, five prototypes completed over 638 flights, demonstrating their effectiveness in all-weather combat scenarios.

The J-7III was officially approved in December 1987, and limited production began, with the first aircraft delivered to the Air Force in December 1989. However, due to its lower maneuverability and shorter endurance compared to earlier J-7 variants, as well as delays in its delivery, it was not well-received. The initial procurement plan for the J-7III was drastically reduced, and production ended in 1996 after only 17 units were built.

J-7IIIA

Spoiler

The J-7IIIA was developed to address the shortcomings of the J-7III, which received negative feedback from pilots after entering service. Pilots primarily criticized the larger forward fuselage, which increased drag and reduced the aircraft’s maneuverability. Although the WP-13 engine enhanced the thrust-to-weight ratio, the increased takeoff weight and unchanged wing area resulted in higher wing loading. The aircraft’s takeoff performance with afterburner was comparable to the J-7II, but its performance at maximum load was worse. During summer operations, the J-7III often required afterburner-assisted takeoffs to shorten the runway roll, leading to greater fuel consumption during takeoff and reducing air time. Increased wing loading also resulted in higher descent and landing speeds, and without blown flaps, the landing performance and handling were inferior to the J-7II. Even with blown flaps, handling characteristics remained suboptimal. Additionally, pilots found the J-7III more difficult to control during medium-altitude horizontal and vertical maneuvers due to increased control forces, leading to fatigue during prolonged maneuvers. Pilots noted that while the J-7III was better at maintaining steady flight than the J-7II, its maneuverability and handling were inferior. Further complaints included poor rear visibility due to the enlarged dorsal fin and the JL-7 radar’s inability to suppress ground clutter, limiting its ability to detect low-flying targets.

To address these issues and improve overall combat capability, Chengdu Aircraft Industry Corporation initiated modifications to the J-7III under the designation J-7IIIA, with Wang Zifang serving as chief designer.

Key improvements included installing the more powerful WP-13FI engine, which increased thrust-to-weight ratio and flight performance. The WP-13FI produced a maximum thrust of 4,511 kg and afterburner thrust of 6,669 kg. The engine featured redesigned first-stage compressors, reducing blades from 24 to 19, increasing airflow, and incorporating boundary layer control technology. Enhancements to thermal shielding, materials, and manufacturing processes allowed for a turbine inlet temperature of 1,015°C. The engine’s first overhaul interval was extended to 300 hours, with a total lifespan of 900 hours.

The avionics and fire-control systems were significantly upgraded, greatly enhancing combat capability. The JL-7A radar replaced the earlier JL-7, and the HK-13A HUD replaced the HK-03D optical gunsight, advancing fire-control targeting capabilities. Additional upgrades included a KJ-11A autopilot, ADS-1 air data computer, JD-3II TACAN navigation system, 563B inertial navigation system, WL-7A radio compass, 265 radar altimeter, TKR-122 UHF radio, as well as compact angular velocity sensors and airspeed/Mach combination instruments. Together, these improved piloting and communication/navigation capabilities. The 930-4 radar warning receiver (RWR) and 941-4A chaff/flare dispenser enhanced survivability. Armament improvements included the installation of the 23-3A twin-barrel cannon and the ability to carry advanced PL-7 and PL-8 infrared-guided air-to-air missiles, increasing offensive capability.

Modification work on the J-7IIIA began in 1988 and was initially implemented on the Chengdu Aircraft Corporation’s J-7III aircraft numbered 151. On August 20, 1991, test pilot Liu Qingli conducted the aircraft’s maiden flight after modifications. The J-7IIIA underwent technical appraisal and entered limited production on November 27, 1994. Its design was formally approved by the Aviation and Military Industrial Product Standardization Committee on December 25, 1995. Despite improvements in combat performance and maintainability, the J-7IIIA did not fully resolve the J-7III’s shortcomings in range and maneuverability. Consequently, production was limited to 32 units, which ceased in 1999. The aircraft was designated the J-7D after delivery to the Air Force.

On October 1, 1999, during the 50th National Day parade, J-7C and J-7D aircraft flew together in formation over Tiananmen Square as part of the celebration.

J-7CP Concept/Programme

Spoiler

In addition to reverse-engineering the MiG-21MF, Chengdu Aircraft Corporation explored other approaches to enhance the J-7’s all-weather combat capability and flight performance. The nose intake design of the J-7 limited its ability to accommodate large radar antennas. To install a multi-functional radar with greater range, the nose space needed to be freed up.