- Yes

- No

- Yes

- No

2b9 AMB vehicle in the picture

History of the 2b9 automatic mortar:

The development of the 2B9 82 mm automatic mortar, the “Cornflower”, began in 1946 in the Soviet Union. The aim of the development was to develop a weapon with a high rate of fire. For the design task, Victor Konstantinovich Filippov a 37-year-old rocket design engineer was invited, who accepted the invitation and preliminary research began. By 1955, the first stand-mounted version “KAM” was completed with the designation (казематный вариант автоматического мино мета), then in 1959 with designation F-82, but they were not serially produced. The self-loading system of the mortar is caused by the backward slide of the barrel. Only in 1967 did they continue and renew the development of the mortar. The final version of the weapon was completed in 1970 and was regularized under the name 2B9 “Vasziljok” in the Soviet Red Army. A couple of years later the weapon was modernised. The weapons water-cooled system was changed to an air-cooled one. In order to increase the cooling surface, the barrel had been provided with ribs. In terms of external appearance, however the only major change was the ribbed barrel. The new version received the name 2B9M. The weapon was manufactured in the Soviet Union by Bolshevik Factory No. 232 in Leningrad (nowadays: GOZ Obukhov factory).

The towed version of the 2b9 was produced in Hungary, the hungarians produced the DE-82. The hungarians developed there own modification from the 2B9 called DE-82, there was a DE-81, the numbers indicate the caliber so the DE-81 has a caliber of 81mm. There is not much difference between the DE-82 and the 2b9, the hungarians modified the 2b9 for their needs. The differences are they installed a hydromassage stop instead of a hydraulic stop. Construction refinement of the height control structure, change of the cooling wheel mechanism in terms of ease of manufacturability and handling. Basically it was easier to manufacture and was more durable than the 2b9.

The purpose of the mortar is to destroy or pin down the enemy and destroy the combat equipment within a short time with a single or a series of bursts, with direct or indirect aiming. The mortar has two firing modes: single that is suitable for firing one shot and one where it fires a series of shots. The mortar has a magazine solution. The mortar is stocked with 24 magazines. There are 4 grenades in a magazine. The mortar was equipped with the PAM-1 optics. 82 mm mortars are primarily considered infantry weapons in terms of their task, but the 82 mm automatic mortar must definitely be classified as an artillery weapon. Advantageous properties of the mortar, ensures the execution of firing flat: from -1° to 20°; curved: from 20° to 45° and steep: from 45° to 85° trajectories alongside. Thus, it can be used for fire support and to defeat armored targets. Based on its structural design, firing at the same distances with various trajectories is ensured, and it is suitable for direct and indirect aiming.

The direct the possible distance of aimed shooting is 1100 m. The practical rate of fire of the automatic mortar is 100-120 shots/min. Based on the ammunition allowance, only 60 grenades are allowed to be fired during a 1-minute firefight. In terms of rate of fire, 1 automatic mortar is capable of firing like 3-4 conventional mortars in 1 minute, which significantly reduces the number of personel needed. The number of operators of the automatic mortar, including the driver of the transport vehicle, is 4 people. The structure of the automatic mortar is quite complicated due to its structural nature and specific weight.

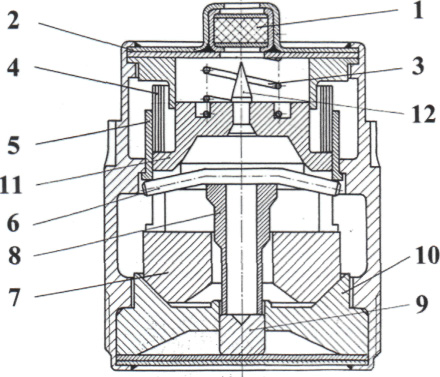

The operation of the machine is based on the forward sliding of the moving parts. At the moment of igniation of the grenade charge, the moving parts will have high kinetic energy. Most of the recoil energy is reused to stop the backsliding of the barrel. The remaining recoil energy is is taken by a mortar structure. The barrel is actually smooth, not like on the 2B9M where there are ribs. The lock mechanism, with the upper and 2 lower reset mechanisms, which are connected to each other by a switch block are connected, thees parts form the moving parts. The feeding mechanism of the weapon automatically activates after each shot, after a shot it feeds a grenade and than it can be fired again.

The PAM-1 optical sight is used to set the mortars barrel in the correct direction in the vertical or horizontal plane, using direct and indirect aiming when shooting. In a combat situation with the mortar, the sight is attached to the sight holder on the left side of the mortar. With the direct sight from -1° to +10° and with the indirect sight aiming can be performed from -1° to +85°. PAM–1 sight is equipped with the LUCS-2 night lighting device.

PAM-1 sight specifications:

Indirect sight

zoom: 2,5x

Field of view: 9 degrees

Direct sight

zoom: 3x

Field of view: 18 degrees

2B9 mortar specifications:

range: 4270 m

velocity of the munition: 270 m/s

practical firing rate: 100-120 rounds per minute

recommended number of ammunition: 226 grenades

caliber: 82 mm

Aiming elevation: Horizontaly: ±30o

Vertically: -1o +85o

the weight of the weapon: 622 kg

History of the 2B9 AMB:

The 82 mm automatic mortar (VASZILJOK) is unique among mortars with its high rate of fire (120 rounds/minute), high accuracy, and the possibility of direct aiming at lower angles. When the domestic development was started, the goal was to develop an armored combat vehicle with the 2B9 with high mobility ( and which could fire from a stationary position) that could carry the large amount of ammunition required for effective use. An additional goal essentially arose from this, as the high mobility justified the fact that the fire control and aiming of the weapon should be sufficiently fast. This was not made possible by the aiming device on the weapon, which is otherwise excellent in its category. It was necessary to develop a fire control system that could complete with the mortar’s excellent combat characteristics and that it could do that operating in several different modes. Using the elements of the fire control system respectively: the position of the target can be measured in the polar coordinate system which is attached to the vehicle with the laser rangefinder operated by the sight, which is also connected to a computer which calculates height, width and firing angles; the longitudinal and transverse tilt of the vehicle can be measured; the lateral and vertical angular position of the mortar can be measured; ground meteorological data can be measured; the temperature of the propellant charge of mine grenades can be measured.

Based on the data, the built-in computer determines the firing angles for the measured distance, taking into account the current inclination of the vehicle and the meteorological data, it determines the required lateral and vertical angular position of the mortar, and controls the servomotors to set the mortar to the firing position. The sight’s electric firing device can start the ignition to fire the grenades. The fire control system can operate in several modes. Its basic operating mode, when the target is visible for the laser rangefinder and if the distance to the target is between 1-4 km. In that case, the gunner can decide whether to fire in the lower or upper angle group (meaning should he fire directly or indirectly). After the decision has been made, the computer indicates if its ready-to-fire and a few seconds after aiming at the target the required number of shots can be fired.

If the target cannot be directly observed, then after occupying a firing position the coordinates are entered in the computer and the computer indicates if its ready to fire. In an emergency, for self-defense purposes, after directly targeting the target, the computer determines the firing elements with a simplified algorithm, and after quick adjustment, the shots can be fired within 1000 m.

In 1992 the 2B9 was installed in the AMB-1 medical transport armored vehicle. The 82 mm automatic mortars were equipped with shrapnel ammunition designed in the fifties (OF-832DU), which are generally not suitable for destroying armored targets. Given that the construction of the automatic mortar is also suitable for firing with direct aim, it seemed appropriate to develop a modern multi-purpose (shrapnel-cumulative) mine munition. Which is the BEKM-82.

Specifications for the 2B9 AMB:

Length: 6805 mm

Width: 2940 mm

Height: 2110 mm

Combat weight: 13,600 kg + 622 kg (the 2B9)

Crew: 3-4 people (driver, commander, loader/gunner and maybe plus one loader)

Vehicle armament: 2B9

Maximum speed: 65 km/h

Average speed on the road: 21.5 km/h

Features: Night vision, laser rangefinder, if implemented a computer which you could fire directly or indirectly with

This is a night vision device which was made so that the crew could check their surroundings at night, and they could check in a 360 degree view meaning they could see all around the vehicle.

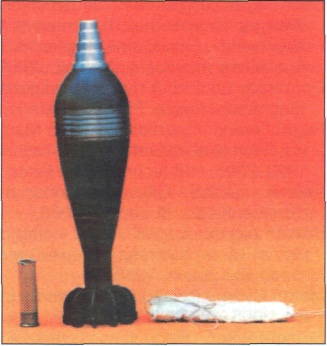

History of the BEKM 82 cumulative munition:

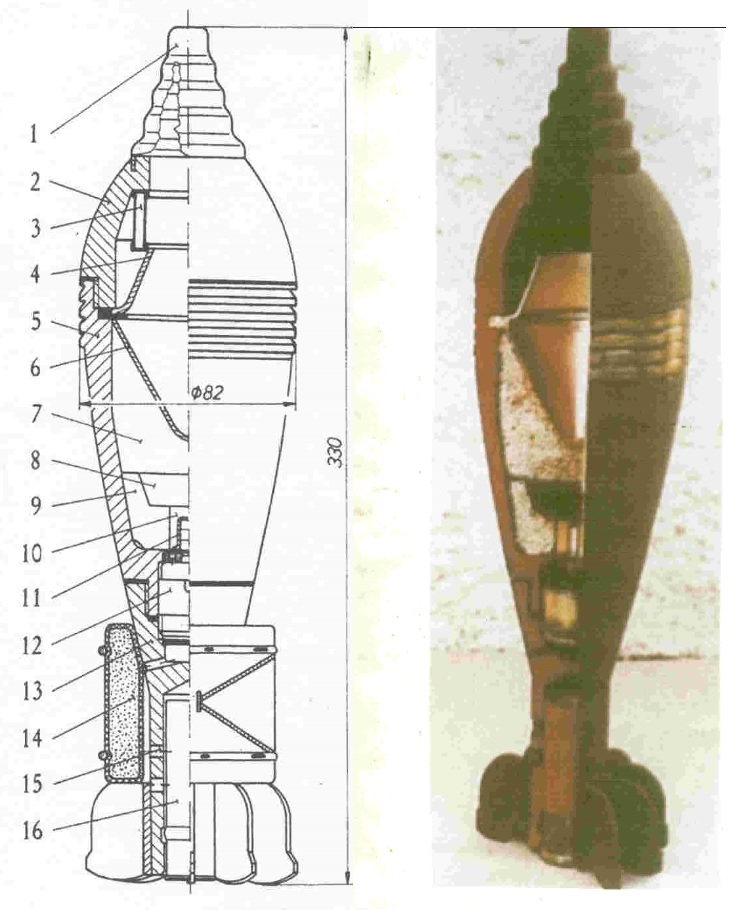

The HM Institute of Military Technology (HTI) developed and tested 82 mm shrapnel-cumulative grenades suitable for destroying armored targets. The goal of the development was to create a new munition that can be fired from both automatic and traditional mortars, and which, while maintaining the shrapnel effect, can also be used to defeat armored targets. The weight of the developed grenade was 3.1 kg, and its armor-piercing capability was 100 mm. The samples were produced at the then Mechanical Works. In the 1970s (the Hungarian Armed Forces still use this type) 82 mm, new type of Soviet ten-wing shrapnel mine grenade (known in the regulations: 82 mm improved ten-wing shrapnel mine grenade - O-832DU) with a fuse, it usually had a cast body, TNT-based explosives and a stabilizer screwed into the body. Their main shortcoming is that they are not suitable for destroying armored targets. The fuzes (M6, M12, etc.) that were in use and used in the Hungarian People’s Army, in case of flat impact angles they do not work, as they do not have a side impact mechanism. The goal was to develop a mine grenade that is suitable for direct and indirect targeting of armored targets and can be used both as an automatic grenade (e.g. 82 mm 2B9M “Vasziljok”) and conventional mine launchers (e.g. 82 mm 37M). It has a cumulative cone suitable for penetrating armored bodies, an igniter with a side-impact structure and a thick-walled body to maintain the shrapnel effect. The shrapnel-cumulative mine grenade is used to defeat and destroy armored targets, concrete fortresses, weakly covered and uncovered forces. The shrapnel-cumulative grenade is equipped with a cumulative liner cone, a mechanical igniter securing gas pressure, high-energy explosive press bodies (hexogen, nitropenta-based) and a flexible ballistic tip that helps the lifting height and the cumulative operation.

The shrapnel-cumulative mine grenade has a steel or cast iron body, split design (lower body and upper body) and thick walls. The lower body has a hole to receive the ignition. The body contains the cumulative liner cone, the DC-1M mechanical breech detonator with gas pressure release with side impact mechanism and the high-energy Á-IX-1 hexogenic explosive. The grenade is equipped with a flexible metal or plastic ballistic tip that ensures a cumulative effect and keeps the ballistic shape factor. The use of the flexible ballistic tip and the split body made it possible to use a mechanical igniter with gas pressure assurance, which made the use of expensive piezoelectric igniters redundant. Structurally, the mine grenade uses the same detonator as used in the PGR shrapnel and PGK cumulative rifle grenades developed for the 7.62 mm AMP rifle. The igniter is a Hungarian-made version of the original Polish design DC-1. That’s why it has the “M” marking on it. The igniter, by the way, was Hungarian-made and manufactured by the Ganz Transport and Measuring Instruments Factory in Budapest.

When the grenade hits the target, the flexible ballistic tip is easily deformed and prevents cracks and breaks in the explosive until the cumulative beam is formed, which would degrade the cumulative effect. The external shape of the flexible ballistic tip is the same as the external shape of the igniter standardized for the grenade at that time. On one hand, this ensures the optimal lifting height required for the cumulative effect, and on the other hand, it is possible to maintain the ballistic factor of the grenade used for the weapon. Of course, the split body structure also contributed to this, which made it possible to keep the weight and center of gravity at their original values. The flexible ballistic tip is threaded to the upper body. The lower body is also threaded to the upper body. The lower body houses the pressed bodies made of high-energy explosives (hexogen, nitropenta-based, etc.), the shielding disk and the detonator with the fuse. The mechanical igniter securing the gas pressure is located in the threaded hole of the lower body. The machined or cast iron stabilizer, in which the starter charge is located, is connected to the lower body with an external thread. The sealing of the threaded connection and the safe operation of the igniter are ensured by the copper disc. The holes are used for the introduction of gunpowder gases to the mechanical igniter that secures against gas pressure. The stabilizer is surrounded by the propellant charges. The starter charge can also be used by itself, because the gas pressure and acceleration it creates ensures the proper functioning of the igniter. The implemented construction provides a significant cumulative and shrapnel effect at the same time, using high-energy explosives. The split upper and lower body made it possible to place the mechanical igniter with gas pressure within the given length dimensions - which is an essential requirement for automatic mortars. This igniter (type DC-1M) is also equipped with a side impact mechanism, which ensures perfect operation even in the event of a flat angle impact. The shrapnel-cumulative grenade can be fired both from traditional and automatic mortars, with any currently regulated launcher charge

The final type designation of the mine grenade became the 82 mm BEKM type shrapnel-cumulative grenade. The type designation was named after the initial letters of the last names of the grenade constructors: Attila Berkesi (Mechanikai Művek), Dr. Elek Tibor. (Military Technical Institute), Ferenc Kocsis (Military Technical Institute), László Molnár dr. (Mechanical Works). In November 1993, the ammunition, together with the 82 mm DE-82 mortar, penetrated the roof armor of an M4 Sherman tank during a successful demonstration in the United States. Later, encouraged by the success of this presentation, in the hope of a possible American or Western export opportunity, in parallel with the development of the 81 mm automatic mortar, the value of the basic size and tolerance of the grenade guide ring was determined in such a way that the mine grenade had a diameter of 81 mm, according to the NATO standards it can also be fired from NATO mortars. But in the same way as the 82 or 81 mm DE type mortar, it was not possible to make a successful export deal with the ammunition either. With the exception of test and “0” series ammunition made from ammunition, a series was completed only for the demonstration held in the USA. This was used in its entirety. The remaining stock in the inventory of the Hungarian Defense Forces was handed over to the Republic of Iraq as aid in 2014.

Specification for the munition:

The length of the ammunition: 330 mm

The diameter of the ammunition: 82 mm

The weight of the ammunition: 3.1 kg

Starting speed 270 m/s from an automatic mortar

from a traditional mortar (3 discs) 210 m/s

Range from automatic mortar 4300 m

3200 m from a traditional mortar

Armor penetration: 100 mm

In game:

It should be a fun vehicle, even at range it would be scary for the enemy. The 120 fire rate with the laser rangefinder would be awesome and the vehicle would have a different playstyle than the rest. The problem with the vehicle is the deppression, -1o is really bad. Even with 100mm of pen it should be really good and do not forget it could overpressure light vehicles.

It should probably be at 5.3 or above that because it has a laser rangefinder and if Gaijin implements the computer, than it could fire into capture points, but Gaijin decides it.

It should be in the game because its unique and it is different than the other vehicles. And the shield should be made so you could close it so it would protect you from enemy machinegun fire, it would be neat.

It would be a fast, nimble vehicle which would be really good at closer ranges because of the fire rate, and at longer ranges it could use the laser rangefinder. The downside of the vehicle is its deppression angle and that its a lightly armoured casemate.

Conclusion of specifications:

PAM-1 sight specifications:

Indirect sight

zoom: 2,5x

Field of view: 9o

Direct sight

zoom: 3x

Field of view: 18o

2B9 mortar specifications:

range: 4270 m

velocity of the munition: 270 m/s

practical firing rate: 100-120 rounds per minute

recommended number of ammunition: 226 grenades

caliber: 82 mm

Aiming elevation: Horizontaly: ±30o

Vertically: -1 degree +85 degree

the weight of the weapon: 622 kg

Specifications for the 2B9 AMB:

Length: 6805 mm

Width: 2940 mm

Height: 2110 mm

Combat weight: 13,600 kg + 622 kg (the 2B9)

Crew: 3-4 people (driver, commander, loader/gunner and maybe plus one loader)

Vehicle armament: 2B9

Maximum speed: 65 km/h

Average speed on the road: 21.5 km/h

Features: Night vision, laser rangefinder, if implemented a computer which you could fire directly or indirectly with. A cumulative round with a great shrapnell effect, with a 100mm pen.

Specification for the BEKM-82 munition:

The length of the ammunition: 330 mm

The diameter of the ammunition: 82 mm

The weight of the ammunition: 3.1 kg

Starting speed 270 m/s from an automatic mortar

from a traditional mortar (3 discs) 210 m/s

Range from automatic mortar 4300 m

3200 m from a traditional mortar

Armor penetration: 100 mm at 90o

Sources:

https://mek.oszk.hu/12900/12993/pdf/12993_4.pdf

Soviet 2B9M Vasilek self-loading mortar - Armament Research Services (ARES)

https://podarilove.ru/hu/vasilek-2-minomet-vasilek/

Önjáró automata aknavető autonóm tűzvezető rendszerrel | Haditechnikai Intézet

82 mm repesz-kumulatív aknagránát | Haditechnikai Intézet

And here you can see the 2B9 being fired