why are yall changing the topic if its about the merky 4’s armor??

Because it’s hopeless.

alan tovarisch’s work MAY help us

I think the devs should review the armor on all Merkavas, especially the Merkavas 4, 3D, and 2D, and to some extent also the Magach Gal Batash and 7C. Essentially all Israeli tanks with modular armor.

Can some one make a bug report ? I think Moderators blocked me, I cannot make bug reports.

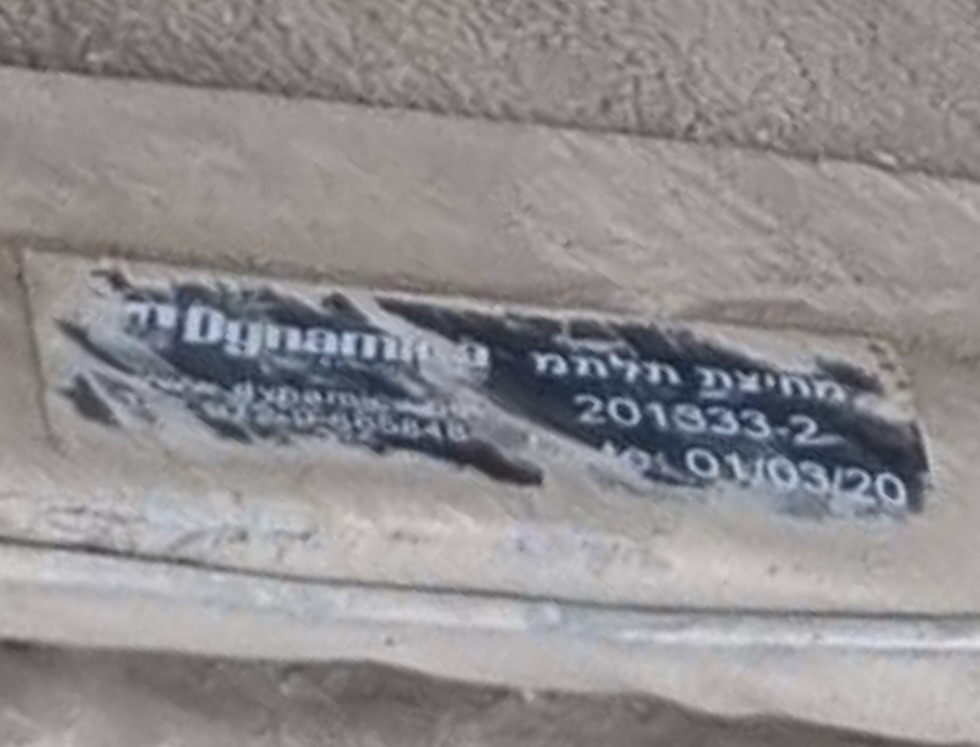

Here are 3 pictures showing spall liners before the crew compartment after the engine. It’s the grey fabric, in the last photo you can see it burned.

These wont hold up to the devs’ standards. The fabric can be anything. Not to mention spall liners are meant to be installed AFTER a piece of armor, as the inner most layer, And not outside the main compartment.

I would support your claim, but during my service on these machines we have never been once told that there are spall liners or that sort of thing in any variant of the Merkava. Unlike the Side plates containing Explosive materials, However on this matter, unfortunately I cannot provide eligible sources :)

Then what is it ? blanket to keep the tank warm ? this spall liner is for catching fragments from the hull armor and engine…

People don’t understand that the presence of the engine and 3 meters of space changes the hit dynamics considerably… after you shatter the penetrators you are now left with catching the fragments. Unlike in other tanks in the merk you just need to shatter the rod into many pieces, and after that they will be caught by the engine or other stuff in the way

Have you ever seen car engine insulation? It’s probably just that.

The heat in those machines is extreme. Insulation mitigates the amount of heat that transfers to the crew compartment

what you are showing is foam… made for insulation. Why does insulating fabric need to be bolted on to the armor ? if it was insulation, they would have clipped it to the tank and that’s it.

That’s for a specific type of Spall reduction mechanism. Other methods do exist (and are employed, such as the preferential use of dual hardness steels) Though they are not taken into account at all.

To some degree the issue is complicated by the fact that the only things taken into account at the moment are the impacted plate’s thickness ( Arbitrarily no plates less than 6mm thick produce secondary spalling, can you subsequently guess which nation(s) just so happen to use said plates to protect their ammo?) and the RHAe value of the material, those with larger values (for a constant quantity of residual penetration remaining) produce a smaller quantity of large (higher) damage chunks across a smaller area which concentrates the damage.

And that all materials are modeled uniformly as generic RHA, where actual performance varies significantly ( see above reference, Figure 21 ) and is evidently not a linear relationship, with for example hardness, as softer materials are worse at resisting penetration, but produce less spall.

Which is why many armor plates are face hardened to very high Brinell values on the exposed face.

so you’re saying that many modern mbt have spall liners even if we can’t see them ?

*Russia ?

Exactly, as far as I know Abrams also have this feature.

It’s more so that liners specifically aren’t the only thing that can reduce spall, at least in comparison to an equivalent quantity of uniform, monolithic RHA.

And that with careful material selection and treatment, Spalling is much less of an issue for modern armor.

it is most certainly something that is taken into account in the design of modern systems, Liners just happen to be a fairly cheap method of refitting system to existing vehicles without extensive work after the fact.

After all we do know that there is a monolithic plate of steel at the back of the baseline Abram’s array that would be there for some reason.

Let alone that the above referenced document makes reference to “Tri-plate” assemblies(PDF page 12), which obviously would permit both a distinct strike-face, and back-plate element to exist, and as such is likely composite made of at least two different materials, with one being a DU infused Steel alloy.

And that the Chobham (which the initial M1’s arrays is based of) uses a “plastic” layer on the strike-face of internal array (laminated) elements, with a further layer of plastic terminal that is bonded to the wall of the fighting compartment.

They are in fact just about fine. The Chinese ones got passed for considerations.

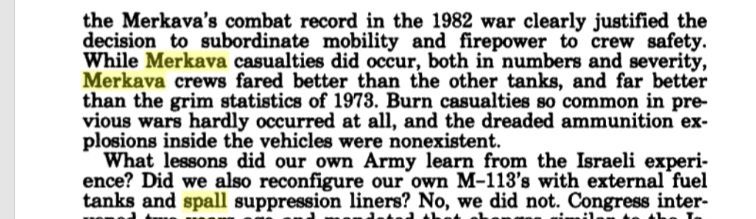

I found a bug report about merkava having spall liners with an evidance from a official washington document about the bradly

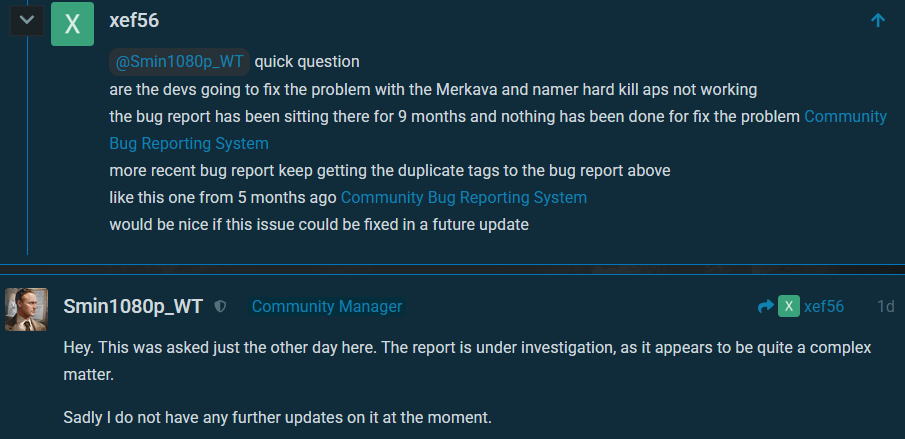

Gaijin said its not a bug ofc

https://community.gaijin.net/issues/p/warthunder/i/IU7Z28C8Si3U

Gaijin devs what do you have to say in your defense?

That’s a mega source lmao.

No correlation between the spall liner and the Merks tho. Only m-113 is mentioned

Huh?

Read the second image